High-speed pure-electric-vehicle planet-gear variable speed transmission system

A pure electric vehicle and variable-speed transmission technology, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of large size and weight of the drive motor, small space, and high motor cost, and achieve easy implementation, low cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

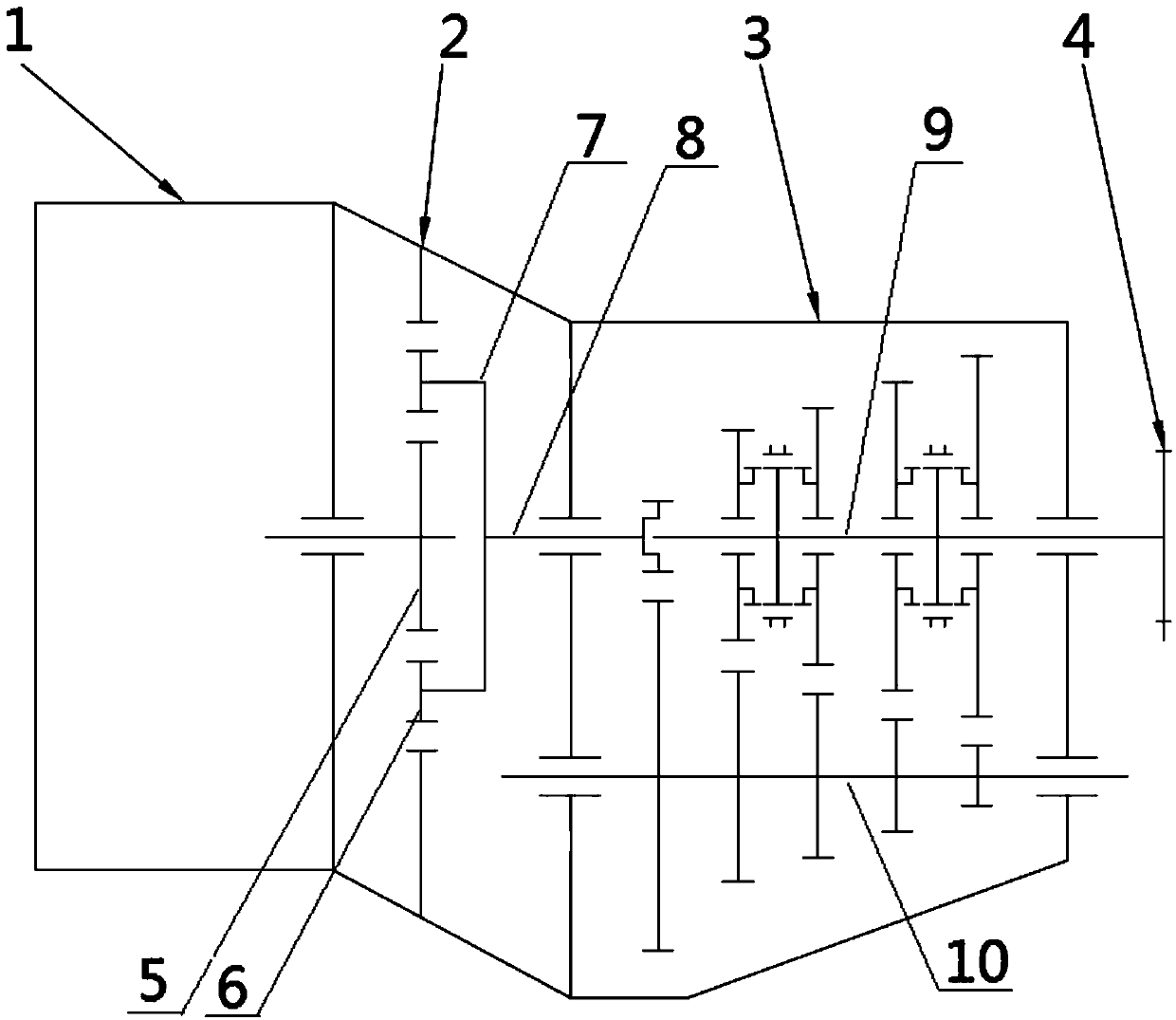

[0022] Such as figure 1 As shown, the present invention uses a high-speed driving motor for a pure electric vehicle variable speed transmission system, mainly including two parts: the high-speed zone 2 of the gearbox and the low-speed zone 3 of the gearbox. The drive motor 1 of the pure electric vehicle transmits power to the high-speed zone 2 of the gearbox through the spline, and the high-speed zone 2 of the gearbox adjusts the speed of the high-speed drive motor 1 to the speed of the traditional car gearbox 3 in front of a shaft 9 through a set of planetary gears The range that can be adapted is suitable for the design, process, production and maintenance of traditional automobile gearboxes.

[0023] The high-speed zone 2 of the gearbox is a planetary gear reduction mechanism, and the low-speed zone 3 of the gearbox is an automobile multi-speed gearbox; the drive motor 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com