Closing coil overhaul apparatus of electromagnetic mechanism

A technology of closing coil and maintenance device, which is applied in the direction of lifting device, switch device, electrical components, etc., can solve the problems of small moving space of the process switch cabinet, damage to the body by the electromagnetic mechanism, difficulty, etc., and achieves convenient installation. The effect of avoiding bodily injury and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

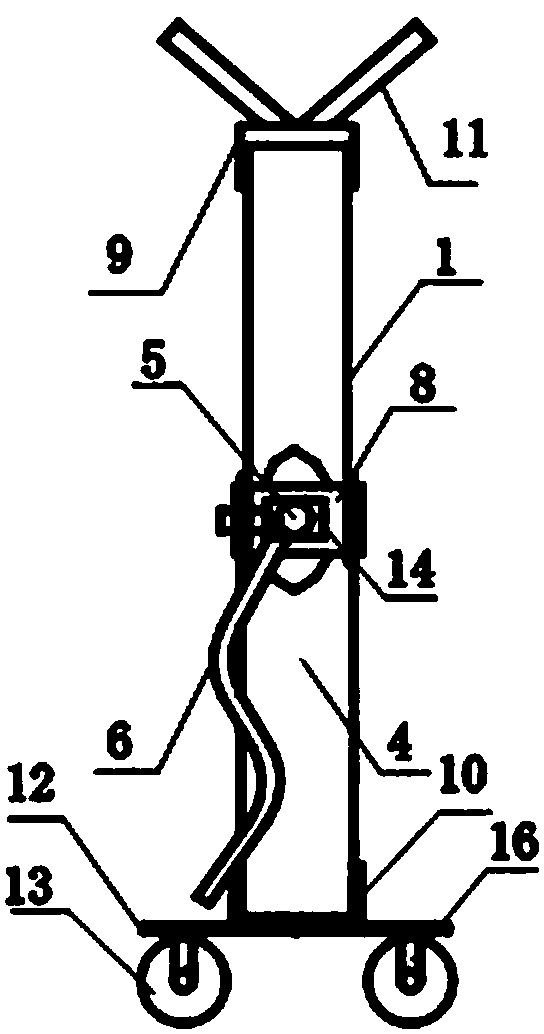

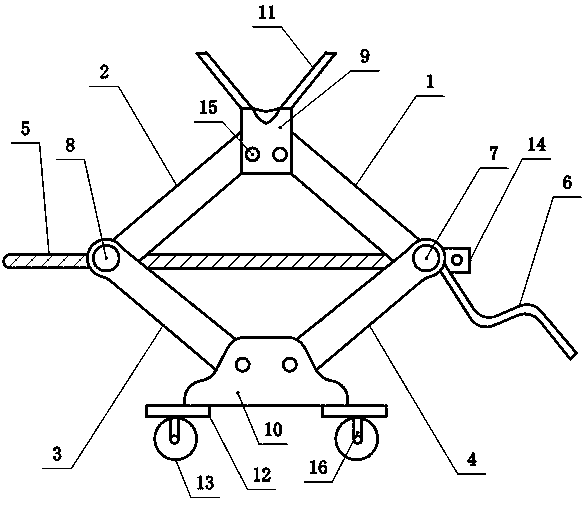

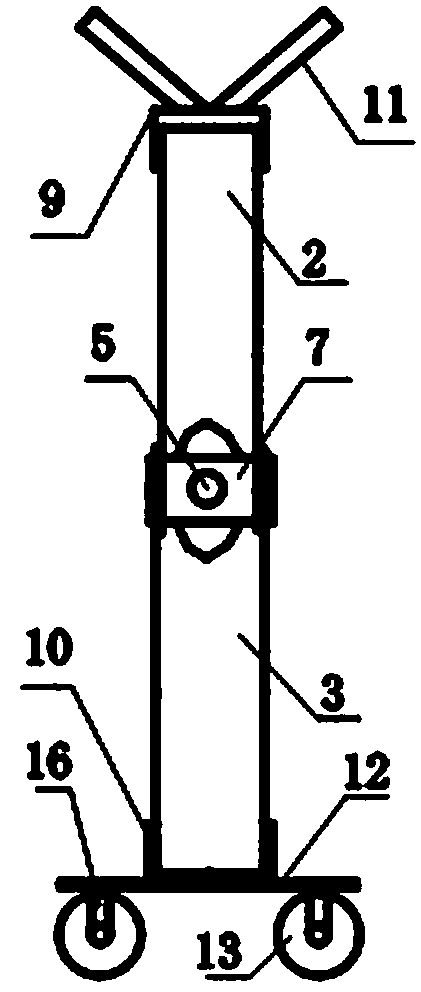

[0023] Embodiment: An electromagnetic mechanism closing coil maintenance device includes a jack and a universal wheel 13. The jack is composed of a bracket, a threaded rod 5 and a hand handle 6. The bracket includes four poles, and the four poles are connected end to end. The first articulated column 7, the second articulated column 8, the third articulated column 9 and the fourth articulated column 10 are respectively used for hinged fixing. One end of the threaded rod 5 is connected with the hand handle 6, and the other end passes through the first articulated column 7. Connected with the third articulated column 9, the second articulated column 8 is fixed with an upper connection and fixed piece, the fourth articulated column 10 is fixed with a lower connection and fixed piece, the upper connection and fixed piece is welded with a fixing frame 11, and the lower connection and fixed piece The lower end is welded with a connecting plate 12, and the connecting plate 12 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com