Acoustic insulator mat with liquid applied sprayable coating and method for making the same

A sound-insulating pad and coating technology, which is applied to the surface coating liquid device, coating, non-woven fabric, etc., can solve the problems of low transmission loss and increased weight of highly sound-absorbing materials, and achieve improved sound-absorbing performance, The effect of resonance effect reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

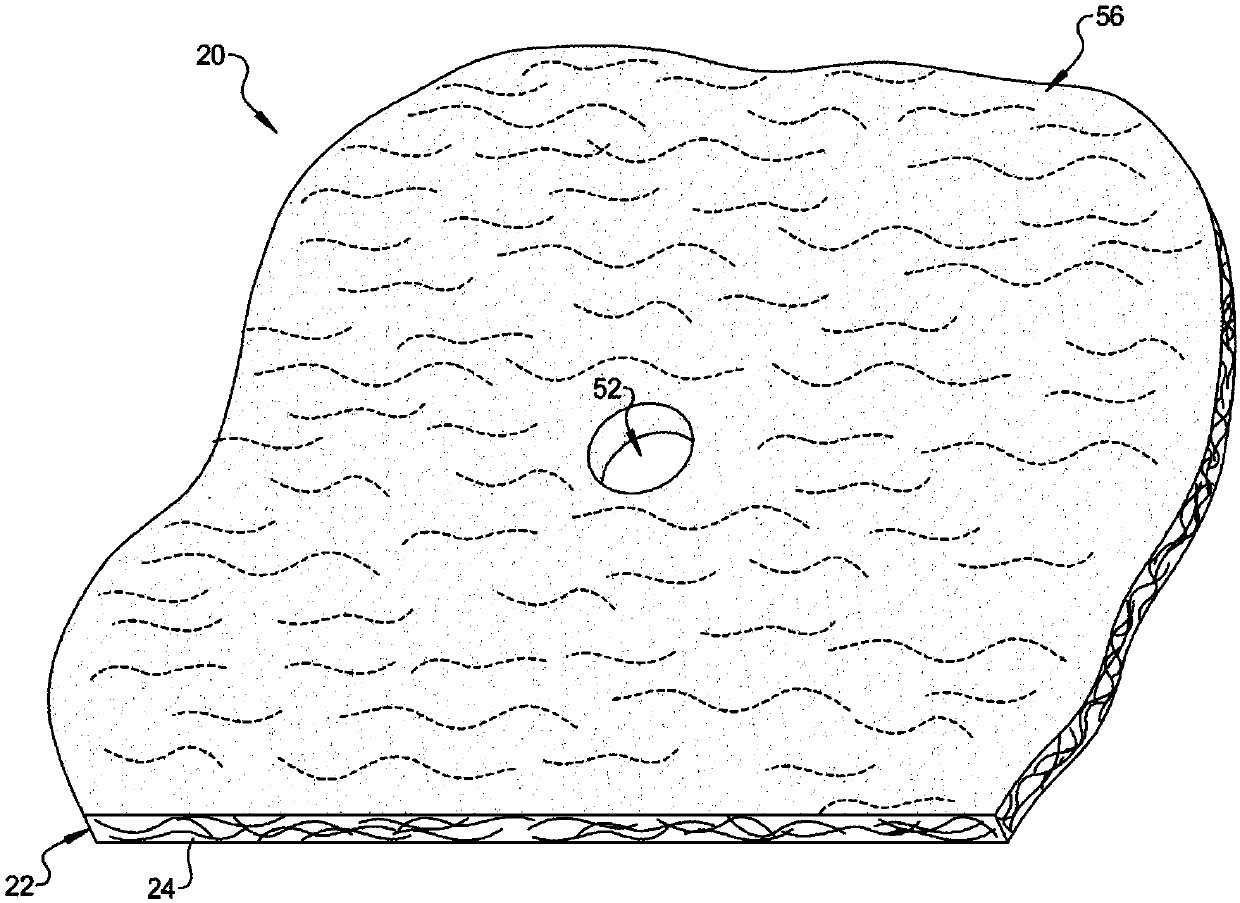

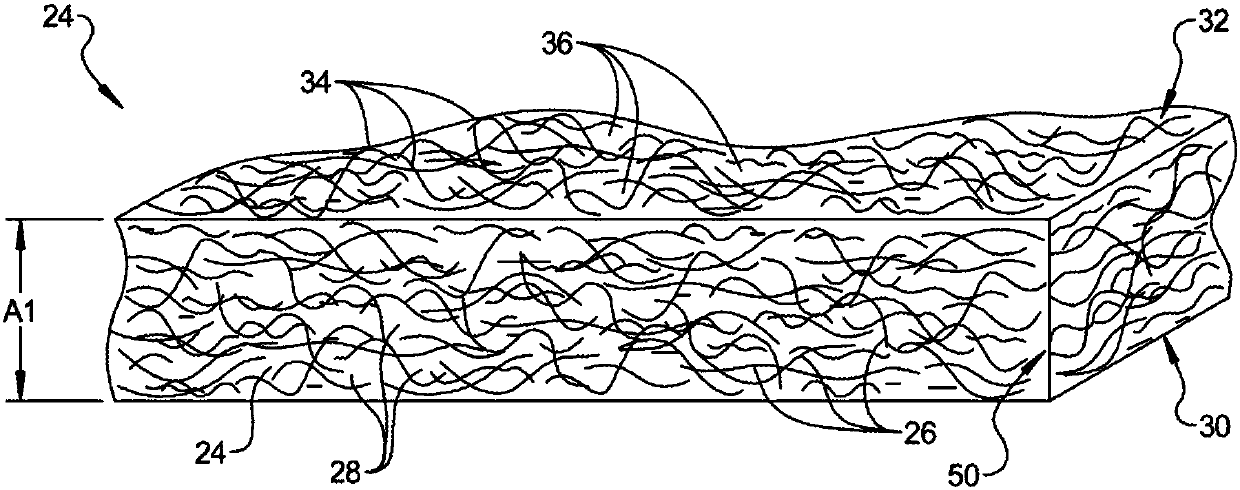

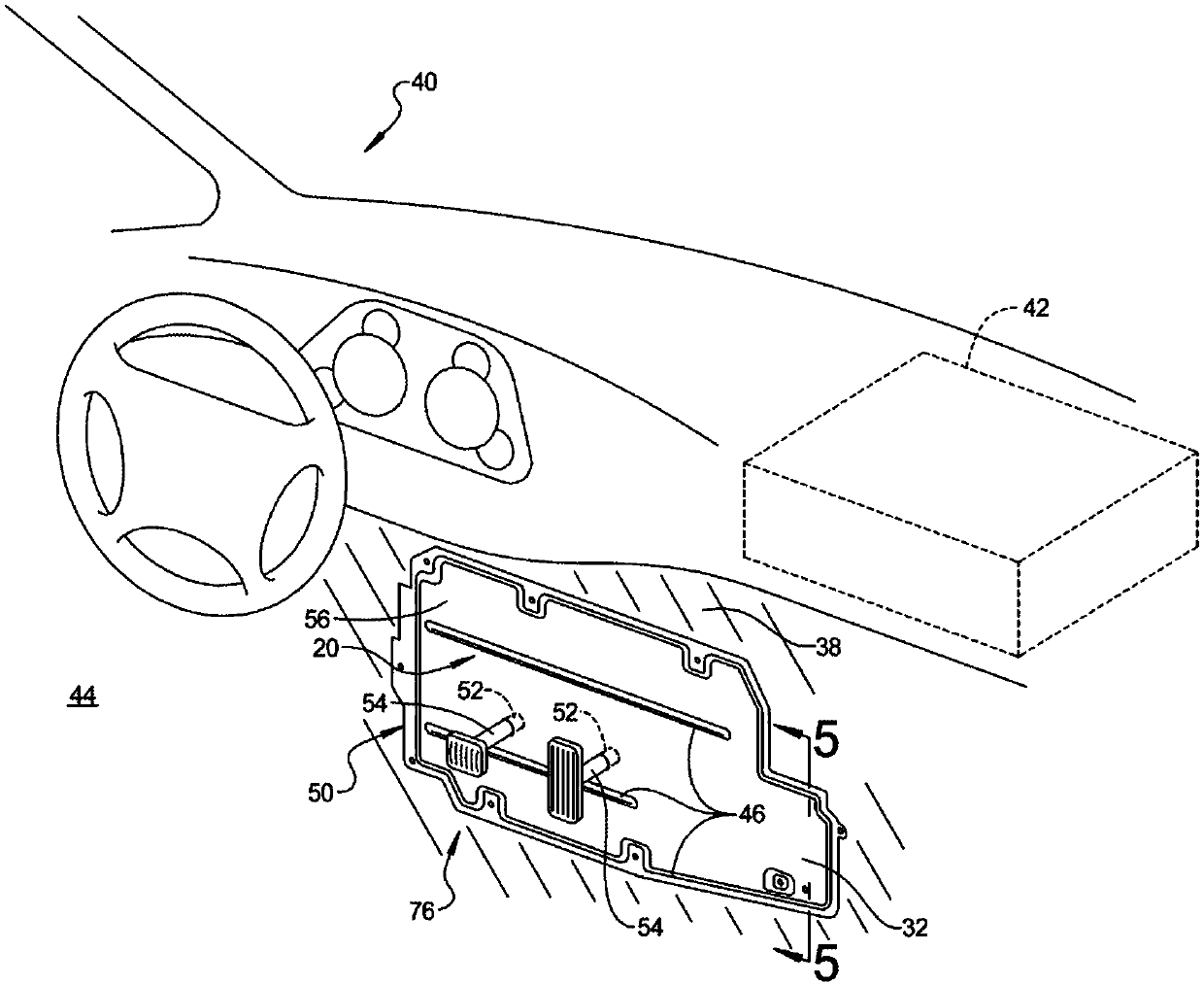

[0030] Referring to the drawings, an acoustic mat 20 is disclosed, wherein like reference numerals indicate corresponding parts throughout the several views.

[0031] The embodiments described above as examples are intended to fully convey the present disclosure to those skilled in the art. Numerous specific details are described, such as examples of specific components, devices and methods, are intended to provide insight into the present disclosure. It will be apparent to those skilled in the art that the above specific details need not be exhaustively employed, that example embodiments may be embodied in many different forms, and that neither should be construed to limit the scope of the disclosure. In some embodiments, well-known processes, well-known device structures, and well-known technologies are not described in detail.

[0032] The terms used herein are used to describe specific embodiments only, and are by no means limiting descriptions. A description of a singul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com