Stir-frying apparatus used for making beef jerky

A technology of beef jerky and pot body, which is applied in the field of stir-frying devices for making beef jerky, which can solve the problems of uneven stirring, rotten beef, and shapeless, so as to avoid appearance, promote uniform mixing, and avoid chipping and scraping. force effect

Inactive Publication Date: 2018-01-19

贵州真安食品有限责任公司

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In view of the above technical problems, the present invention provides a stir-frying device for making beef jerky to solve the technical problems that the existing beef jerky stir-fry pot is not evenly stirred, and the beef is not formed when it is stirred.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention will be further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

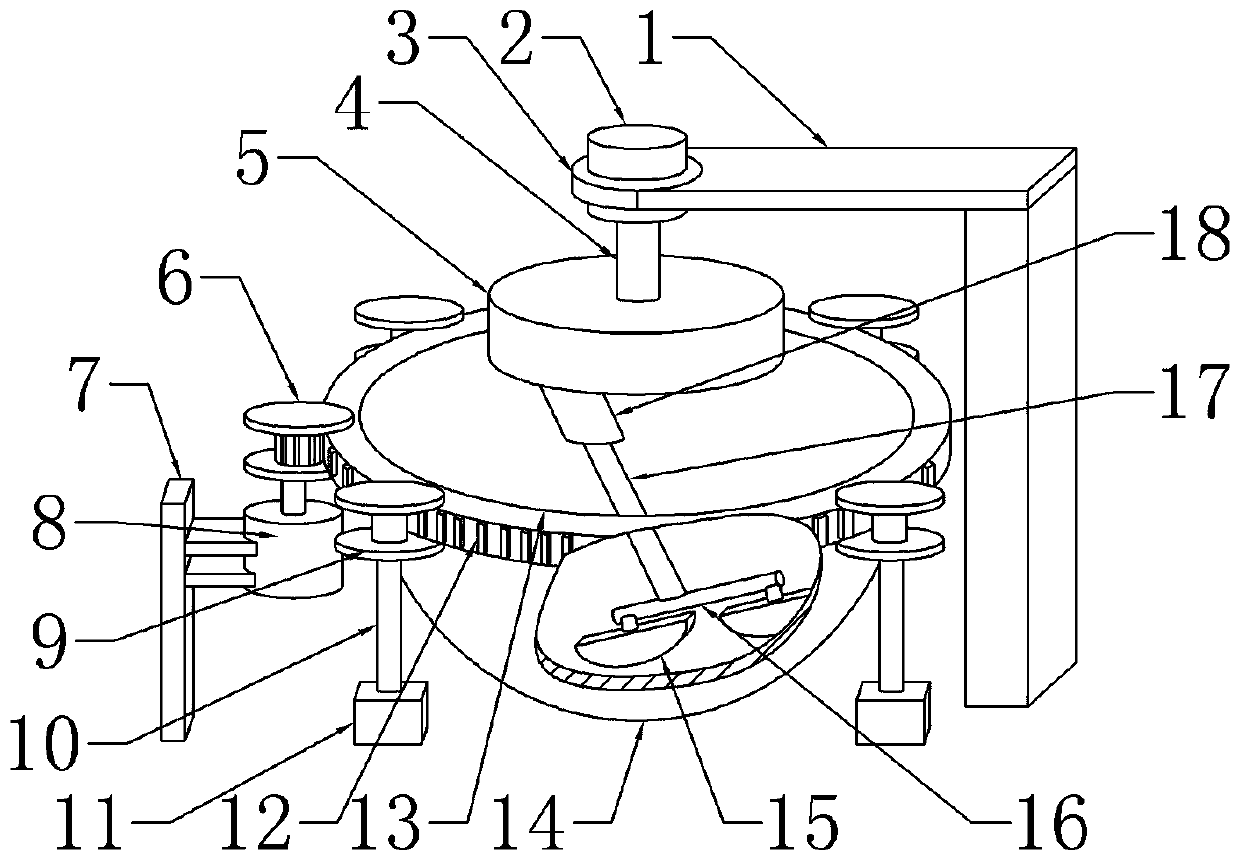

The invention discloses a stir-frying apparatus used for making beef jerky, and belongs to the field of food processing equipment. The stir-frying apparatus used for making the beef jerky comprises ahemispherical pan, a stirring mechanism, and a support used for supporting the pan; the stirring mechanism comprises a stirring motor, a rotating disk, and a stirring unit; the stirring unit comprisesa driving gear, a driven gear meshed with the driving gear, and a stirring shaft connected with the driven gear; a cavity is arranged in the rotating disk; an output shaft of the stirring motor penetrates through a top of the rotating disk, and stretches into the cavity in the rotating disk, wherein the output shaft of the stirring motor is connected to the top of the rotating disk; a through hole is arranged at a bottom of the rotating disk, and communicates with the cavity; the driving gear and the driven gear are located in the cavity; the driving gear is connected with the output shaft ofthe stirring motor; the stirring shaft penetrates through the through hole; stirring blades are connected to a lower end of the stirring shaft; and lower edges of the stirring blades contact with aninner wall of the pan. By utilizing linkage effects, the stir-frying apparatus is capable of allowing rotation and revolution of the stirring shaft so as to realize full mixing of the beef with the seasonings.

Description

technical field [0001] The invention relates to the field of food processing equipment, in particular to a stir-frying device for making beef jerky. Background technique [0002] Beef jerky is generally used for beef marinated with yellow beef and other seasonings. [0003] Beef is the second largest carnivorous food in China, second only to pork. Beef has high protein content, low fat content, delicious taste, and is loved by people. It enjoys the reputation of being the favorite of meat. Beef jerky contains a variety of minerals and amino acids needed by the human body, which not only maintains the chewy flavor of beef, but also keeps it from deteriorating for a long time. [0004] The processing flow of beef jerky is: meat selection, segmentation, soaking, cooking, cutting, frying, baking, inspection, packaging and storage. When frying, the currently used wok is a drum-type stirrer, including a drum and a stirring shaft arranged in the drum. The stirring shaft is provid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23L5/10B01F9/22B01F9/12B01F15/00B01F29/83B01F29/90

Inventor 王建军

Owner 贵州真安食品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com