A driving mechanism for corn grain cleaning screen

A technology of driving mechanism and cleaning screen, which is applied in the fields of filtering, solid separation, chemical instruments and methods, etc. It can solve the problems of high vibration and noise, complex driving mechanism and uncompact structure, etc., and achieve stable operation and clean operation. The effect of high selection efficiency and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

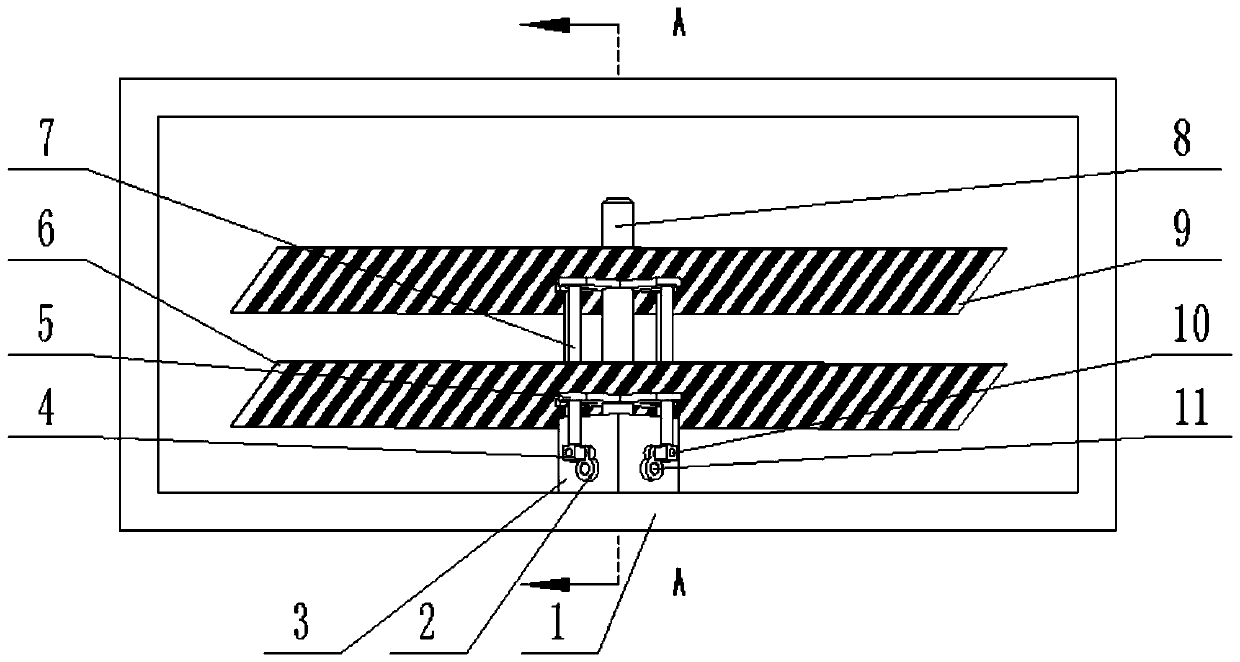

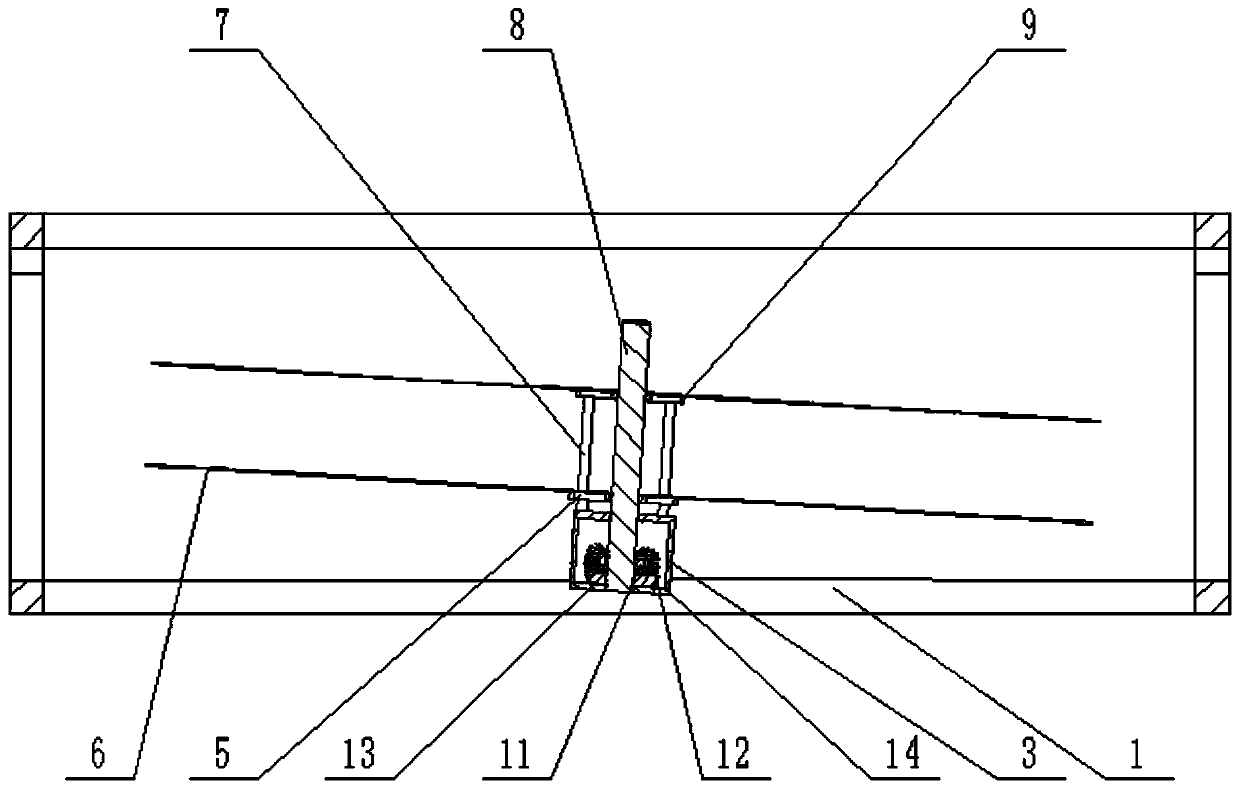

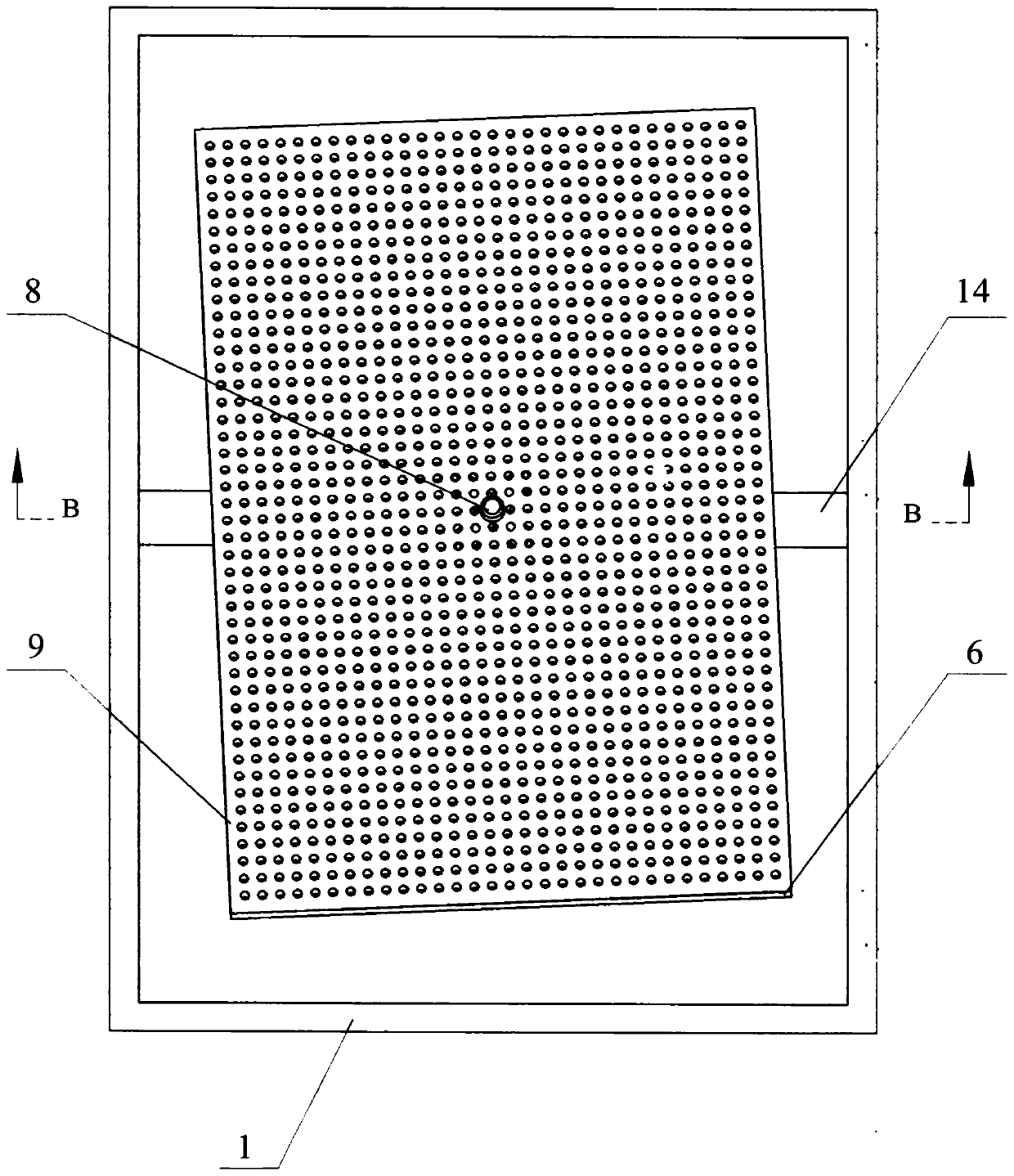

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A corn grain cleaning sieve drive mechanism includes an upper sieve 9 and a lower sieve 6, a support beam 14 is fixed on the bottom side of the sieve box frame 1, and a gearbox housing 3 and a column are respectively fixed on the support beam 14 Slideway 8, described column slideway 8 is positioned at the central part of gear box housing 3, and driving bevel gear 13 and four driven bevel gears 12 are installed in described gear box housing 3, and described driving bevel gear 13 Engaging with four driven bevel gears 12, the four driven bevel gears 12 are respectively fixed with four gear shafts 11, and the four gear shafts 11 are fixedly connected with four connecting rods 2 respectively, and the four driven rods 10 They are fixed on the four connecting rods 2 respectively, and the four driven rods 10 respectively rotate circumferentially and axially move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com