Remote control system for spraying, dissolving and cleaning of camera shield

A technology of remote control system and protective cover, applied in the direction of transmission system, cleaning method and appliance, TV system components, etc., can solve problems such as inconvenient, time-consuming, labor-intensive, low efficiency, etc., to improve cleaning ability and reduce difficulty , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

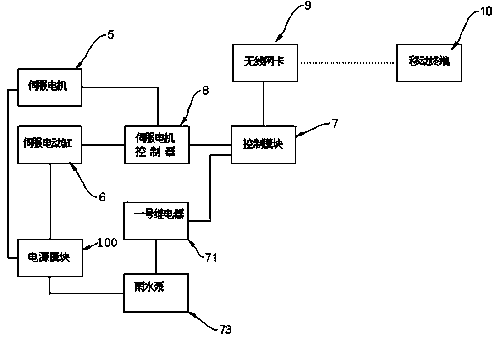

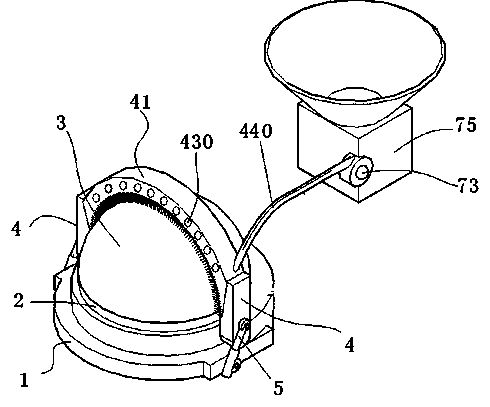

[0025] Refer to attached image 3 , attached Figure 5 , attached Image 6 And attached Figure 7 , a remote control system for spraying and dissolving cleaning of a camera protective cover, comprising a camera body 21, a base 1, and a protective cover 3, a rotating disc 2 is installed on the base 1, and the camera body 21 is installed on the rotating disc 2 to protect The cover 3 covers the camera body 21 on the rotating disk 2, and the base 1 is equipped with a servo motor 5 for driving the rotating disk 2 to rotate; Brush 41; also includes a servo electric cylinder 6, the cylinder body of the servo electric cylinder 6 is hinged on the base 1, the end of the ejector rod of the servo electric cylinder 6 is hinged on the cleaning brush bracket 4, and the servo electric cylinder 6 can push the cleaning brush bracket 4 Rotate to send the cleaning brush 41 to the top of the protective cover 3; refer to the attached figure 1 , also includes a control module 7, a power module 1...

Embodiment 2

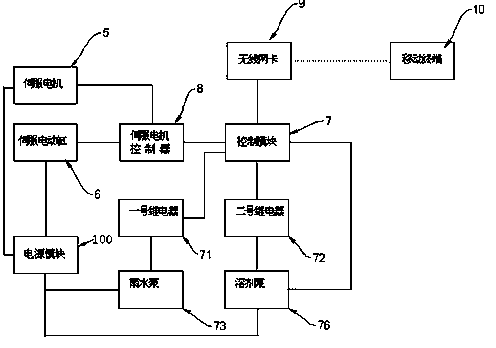

[0029] Refer to attached figure 2 , attached Figure 5 , attached Image 6 And attached Figure 7 , a remote control system for spraying and dissolving cleaning of a camera protective cover, comprising a camera body 21, a base 1, and a protective cover 3, a rotating disc 2 is installed on the base 1, and the camera body 21 is installed on the rotating disc 2 to protect The cover 3 covers the camera body 21 on the rotating disk 2, and the base 1 is equipped with a servo motor 5 for driving the rotating disk 2 to rotate; Brush 41; also includes a servo electric cylinder 6, the cylinder body of the servo electric cylinder 6 is hinged on the base 1, the end of the ejector rod of the servo electric cylinder 6 is hinged on the cleaning brush bracket 4, and the servo electric cylinder 6 can push the cleaning brush bracket 4 Rotate to send the cleaning brush 41 to the top of the protective cover 3; refer to the attached figure 2 , also includes a control module 7, a power module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com