Radial scraper

A scraper and cutter head technology, applied in the field of radial scrapers, can solve the problems of unsatisfactory requirements and slow smoothness of ball cutter milling, and achieve the effect of high efficiency and high smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

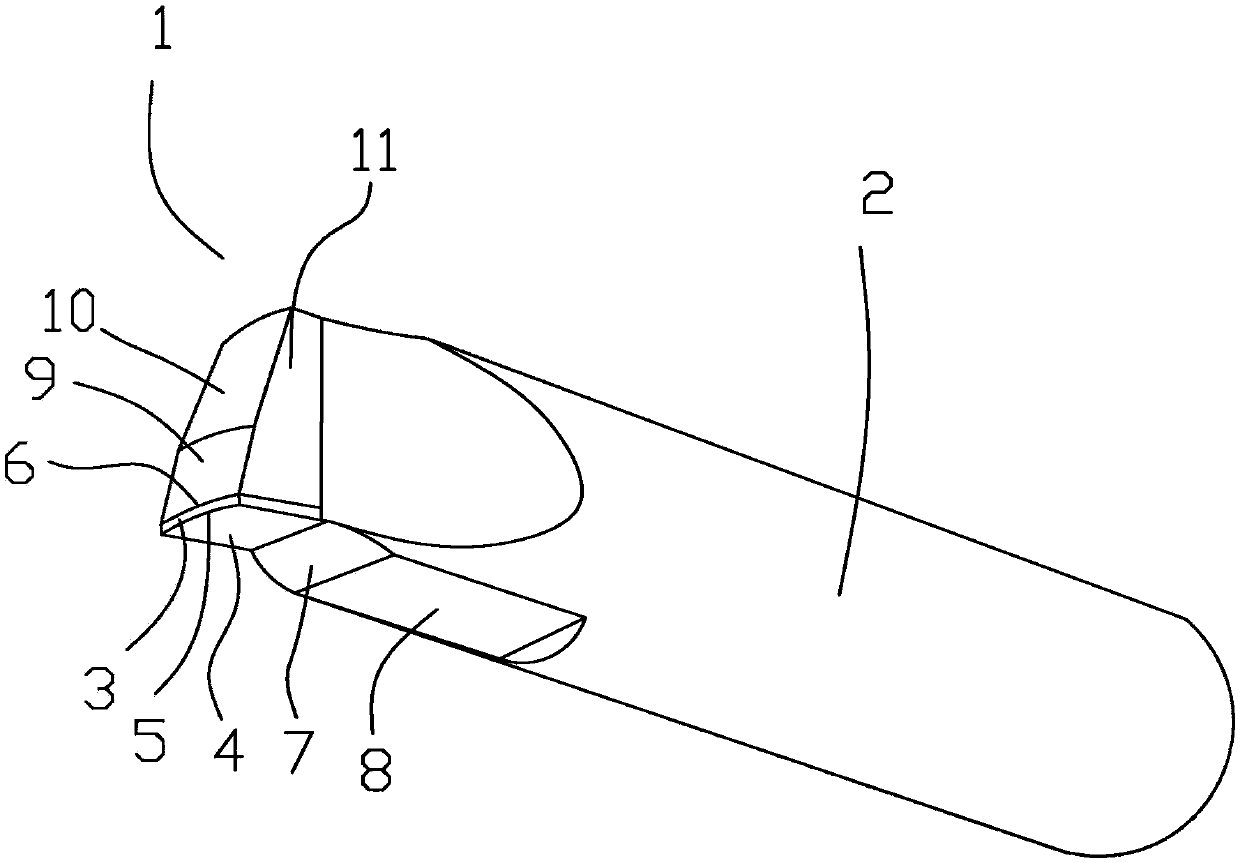

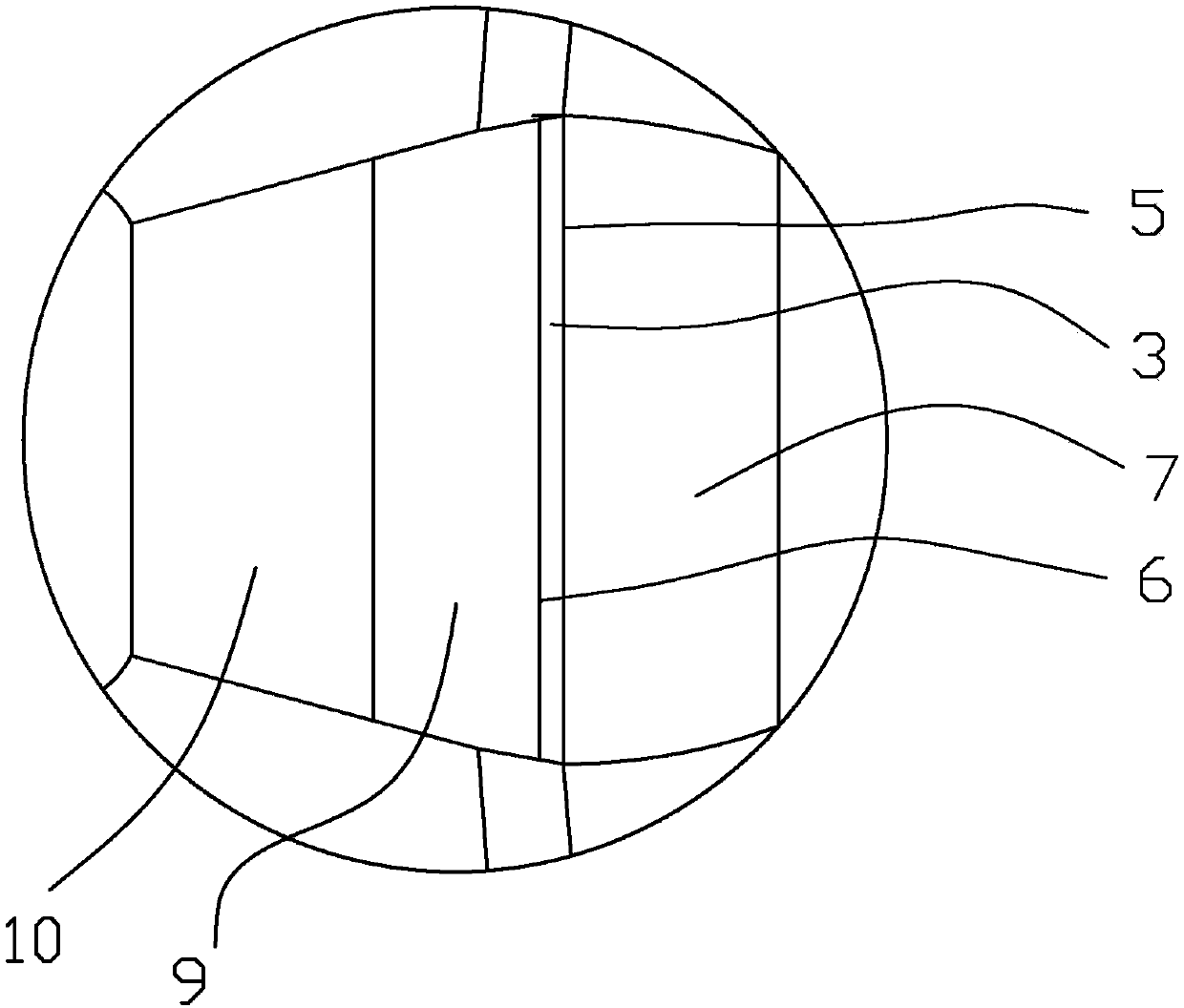

[0013] refer to figure 1 , figure 2 , the invention discloses a radial scraper, including a cutter head 1 and a cutter bar 2, the cutter head 1 includes a scraping edge surface 3, a rake surface 4 and a flank surface, and the flank surface and the scraping edge surface 3 Both are arc-shaped surfaces, the scraping edge surface 3 intersects with the rake face 4 to form the first cutting edge 5; the scraping edge surface 3 intersects with the flank surface to form the second cutting edge 6, so that the first cutting edge 5 and The second cutting edge 6 is arc-shaped, so that the arc-shaped groove can be scraped out. The knife bar 2 is provided with a transition surface 7, which can play the function of chip removal through the transition surface 7, and can avoid The problem of stress concentration can avoid reducing the strength of the cutter head 1. The transition surface 7 is in contact with the rake face 4, and the distance between the first cutting edge 5 and the apex of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com