Glass automatic edge grinding machine for camera protection lens

An automatic edging machine and lens protection technology, which is applied to machine tools, grinders, and grinding drives suitable for grinding workpiece edges, can solve problems such as labor-intensive handling of fixtures, labor-intensive processes, and electricity costs. Achieve the effect of improving edge yield, saving operator labor, and simplifying workflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

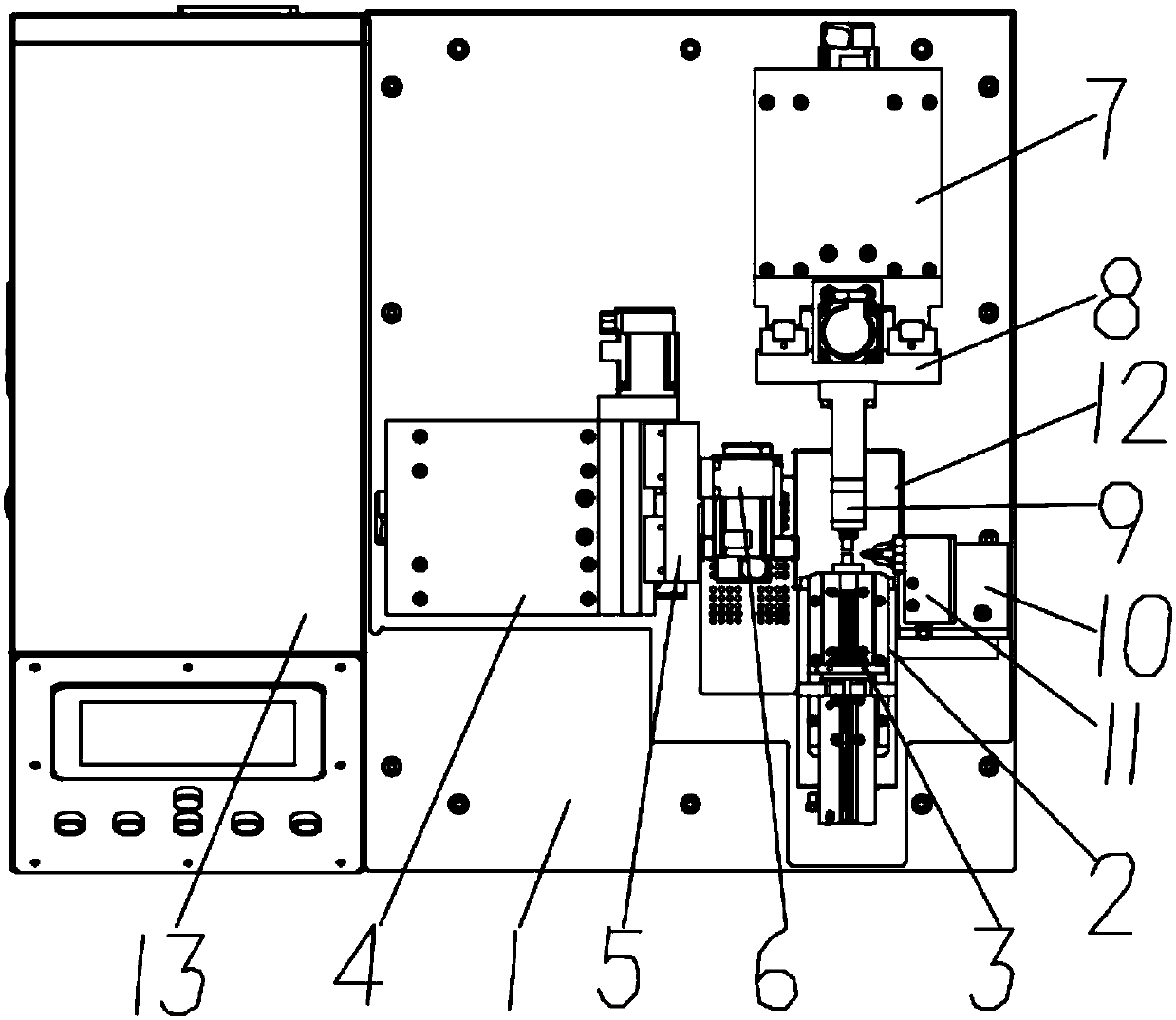

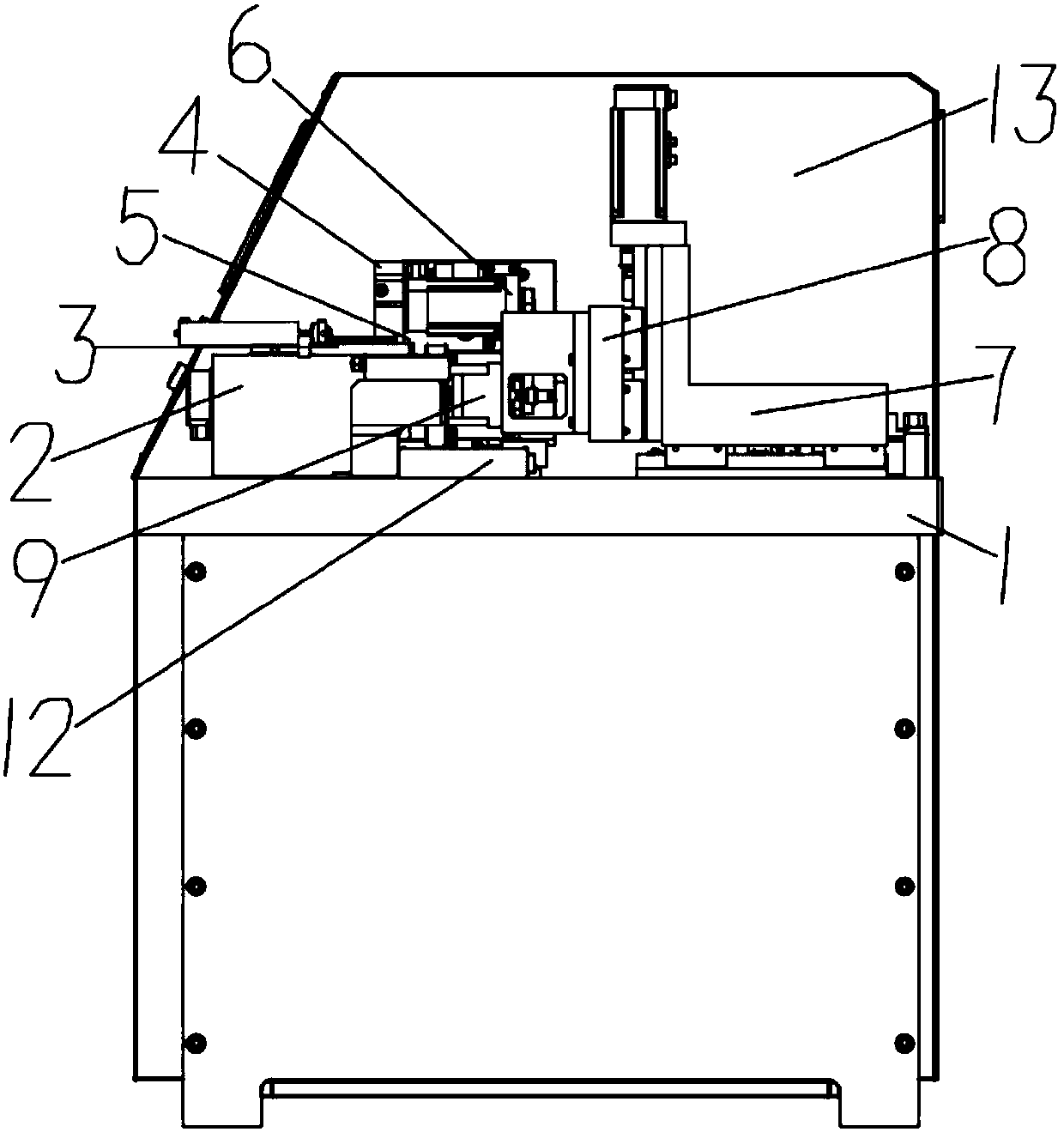

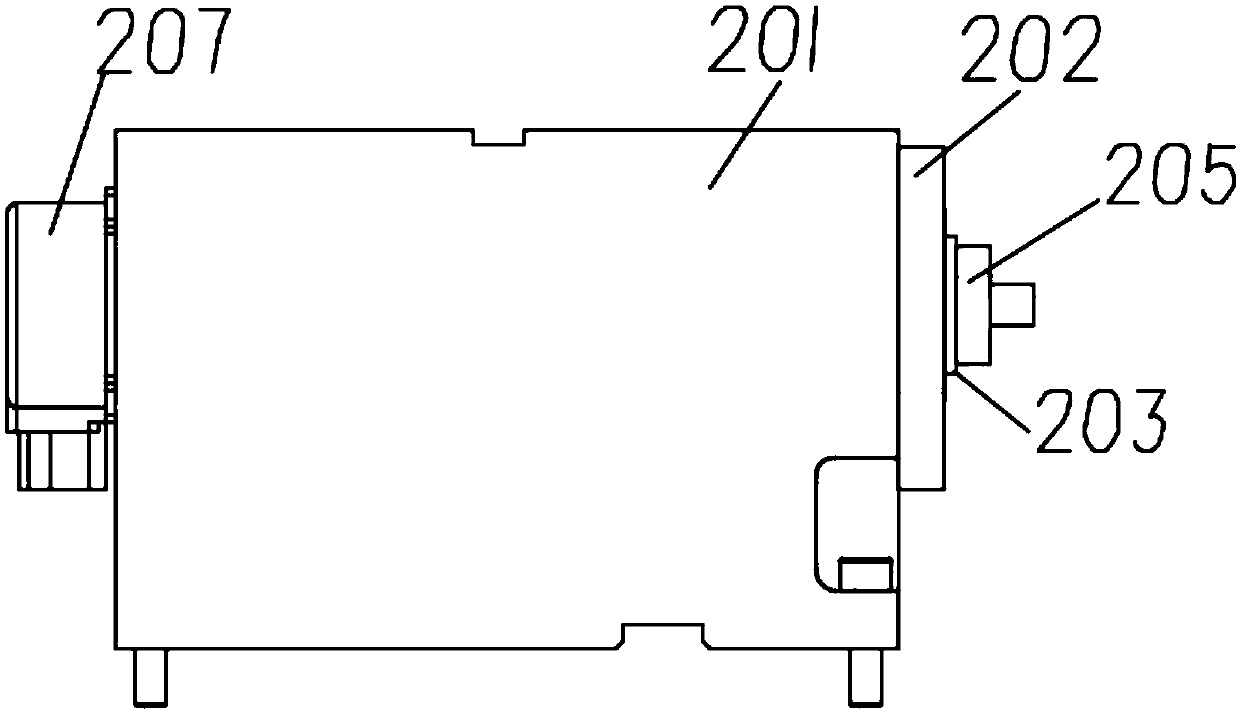

[0058] Such as Figure 1 to Figure 4 As shown, the present invention provides an automatic glass edger for camera protection lenses, comprising a frame 1 and a rotary station 2, the rotary station 2 is fixedly mounted on the frame 1, and the rotary station 2 includes a rotary Station seat 201, the two ends of the rotary station seat 201 are respectively equipped with a main shaft seat 202 and a rotary servo motor 207, the main shaft seat 202 is equipped with a main shaft 203 through a bearing 204, and a supporting seat 205 is movably installed on the main shaft 203 , the rotary servo motor 207 drives the main shaft 203 to rotate through the rotary coupling 206, the support base 205 rotates synchronously through the main shaft 203, and the finished product collection device 12 is arranged under the support base 205, and the finished product collection device 12 has structure, and the finished product collection device 12 is a detachable design structure, and a control box 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com