Automatic feeding device of shot blasting machine

An automatic feeding and shot blasting machine technology, applied in the direction of grinding/polishing safety devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of hopper shaking, no limit slot, and no feeding device Moving and other issues, to achieve the effect of easy to use, easy to move up and down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

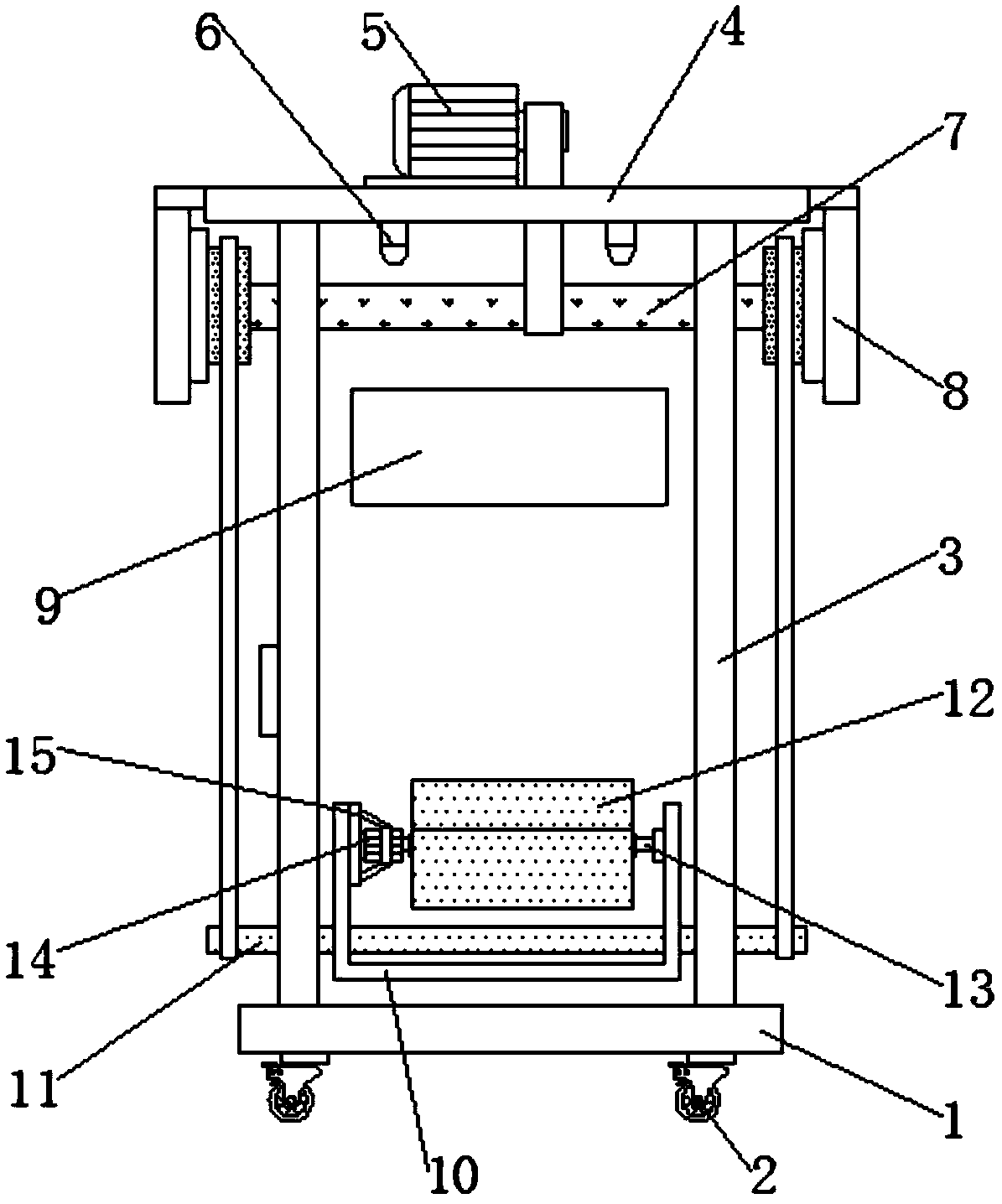

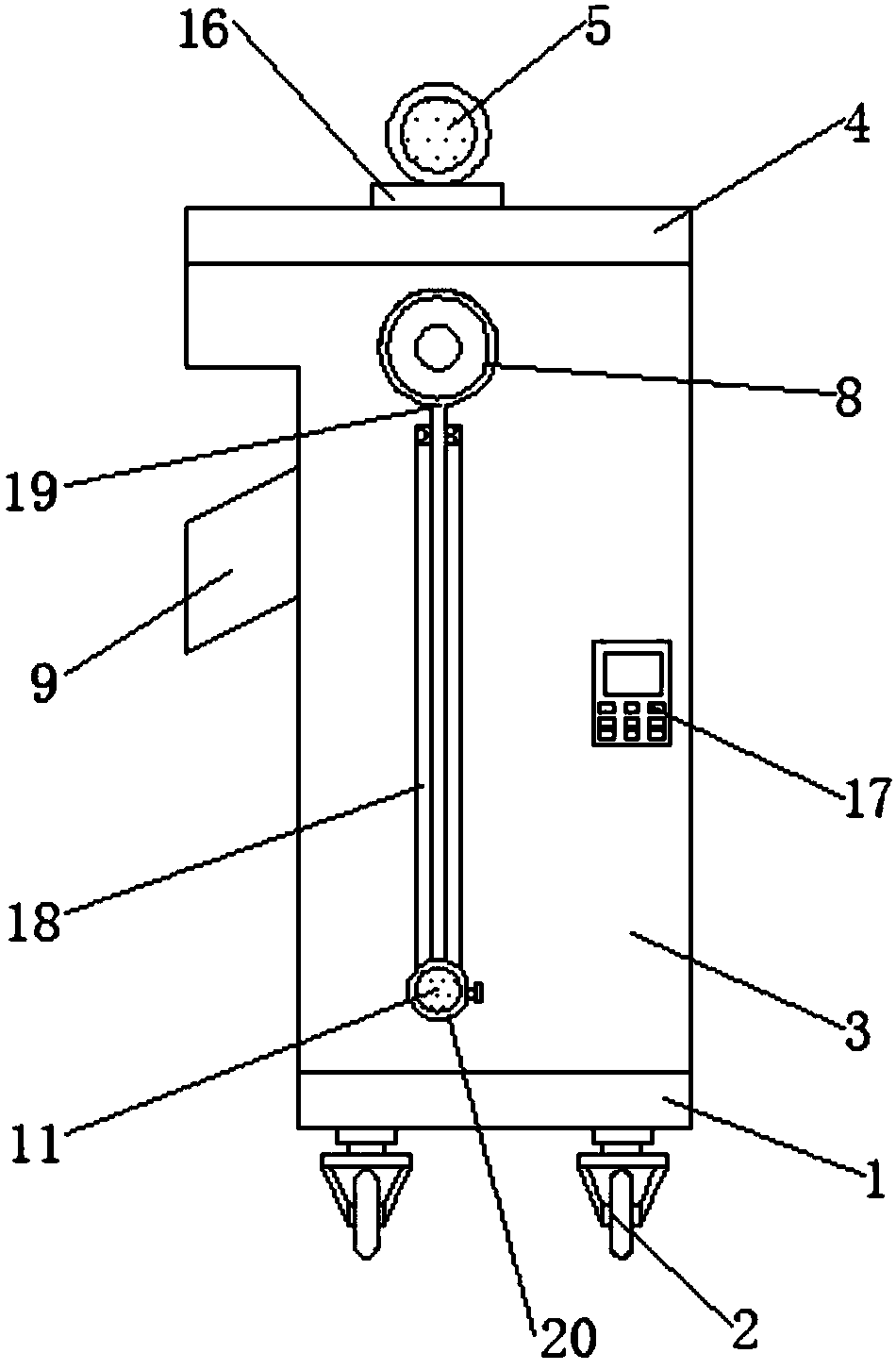

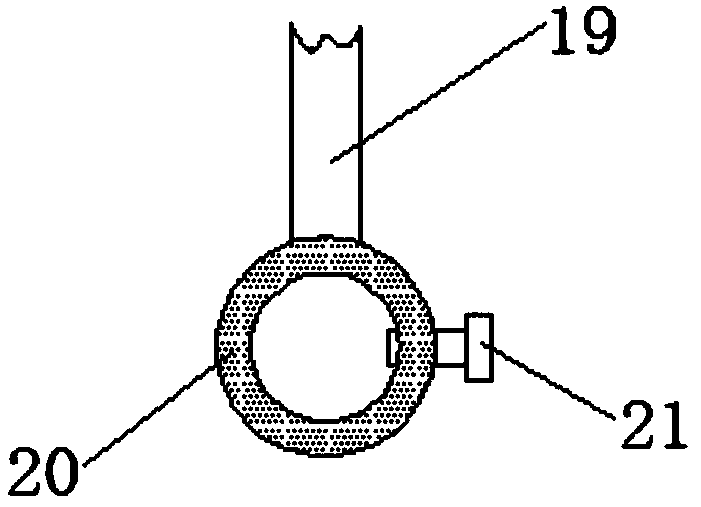

[0024] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, an automatic feeding device for a shot blasting machine, including a support base 1, a universal wheel 2 is installed on the bottom end of the support base 1, and a protective plate 3 is connected to the top end of the support base 1 , the top of the protective plate 3 is connected with a fixed plate 4, the first servo motor 5 is installed above the fixed plate 4, the bottom end of the first servo motor 5 is provided with a rubber pad 16, and the bottom end of the fixed plate 4 is equipped with an LED lighting lamp 6. A first rotating shaft 7 is inserted in the inner part of the protective plate 3 close to the lower position of the LED lighting lamp 6. The two ends of the first rotating shaft 7 are connected to the two sides of the protective plate 3 with a take-up reel 8, and the protective plate 3 The rear side of the rear side is connected with the feed inlet 9 near the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com