Electric control flat-tyre hedging system

A puncture, electronic control technology, applied in tire measurement, tire parts, transportation and packaging, etc., can solve problems such as reducing the degree of danger, and achieve the effect of ensuring safety, restoring control ability, and ensuring balanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

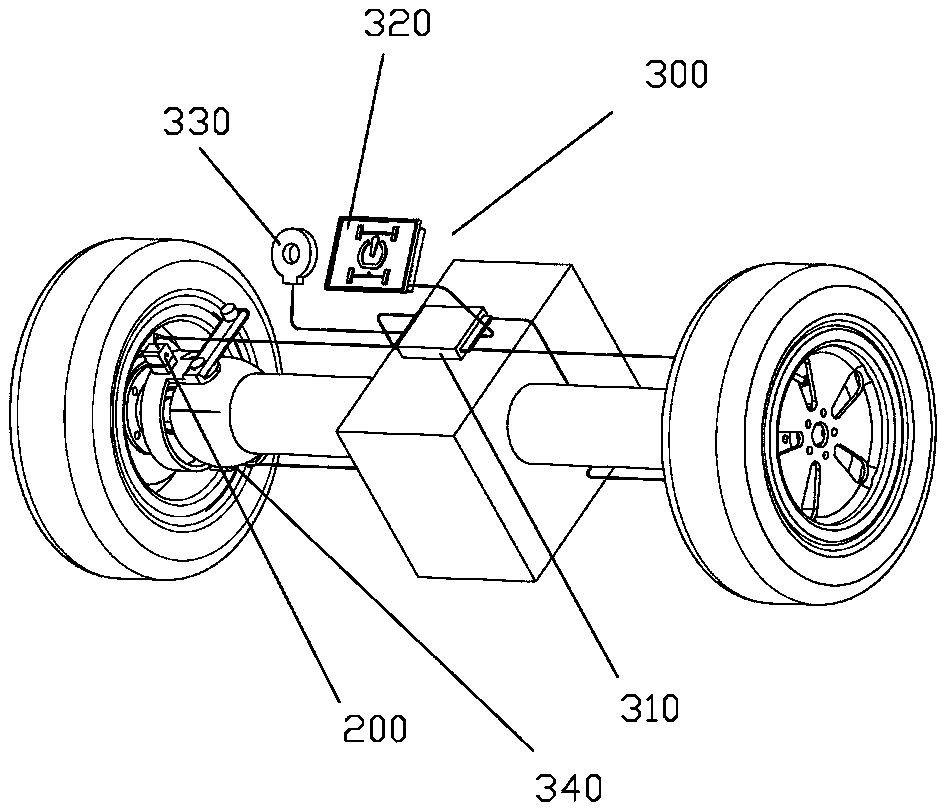

[0032] like figure 1 As shown, the electronically controlled tire blowout avoidance system includes a deflation valve 100 installed on the tire, a linear motor 200 for controlling the deflation valve and a motor control system 300 for controlling the linear motor; the motor control system 300 It includes an electronic control unit 310, a tire pressure detection system 320, a wheel speed sensor 330 and a steering wheel angle sensor 340; , when the electronic control unit 310 receives an abnormal signal from the tire pressure monitoring system 320, it will refer to the instant wheel speed signal and the steering wheel angle signal sent back by the wheel speed sensor 330 and the steering wheel angle sensor 340 to determine whether to issue a working command to the linear motor 200 judgment; when the electronic control unit 310 makes the judgment of sending an operating command to the linear motor 200, it immediately sends an operating command to the linear motor 200, so that the ...

Embodiment 2

[0043] like figure 1 As shown, the electronically controlled tire blowout avoidance system includes a deflation valve 100 installed on the tire, a linear motor 200 for controlling the deflation valve and a motor control system 300 for controlling the linear motor; the motor control system 300 It includes an electronic control unit 310, a tire pressure detection system 320, a wheel speed sensor 330 and a steering wheel angle sensor 340; , when the electronic control unit 310 receives an abnormal signal from the tire pressure monitoring system 320, it will refer to the instant wheel speed signal and the steering wheel angle signal sent back by the wheel speed sensor 330 and the steering wheel angle sensor 340 to determine whether to issue a working command to the linear motor 200 judgment; when the electronic control unit 310 makes the judgment of sending an operating command to the linear motor 200, it immediately sends an operating command to the linear motor 200, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com