Wall climbing operation robot suitable for moving on variable-curvature wall surface

A technology of operating robots and variable curvature, which is applied in the direction of motor vehicles, tracked vehicles, transportation and packaging, etc., can solve the problems of inability to flexibly adapt to surface changes, robot movement failure, lack of flexibility, etc., to avoid underpinning or movement failure, The overall structure is simple and compact, and the effect of convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the embodiments and accompanying drawings, but this should not be used as a limitation to the protection scope of the claims of the present application.

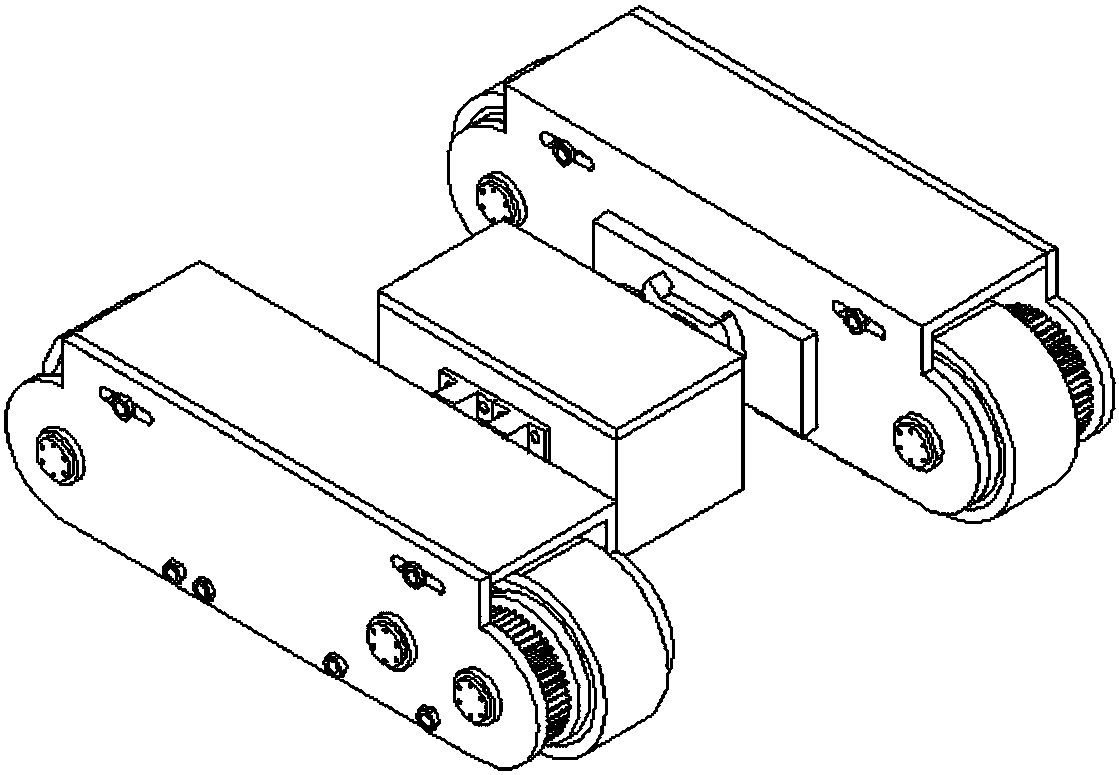

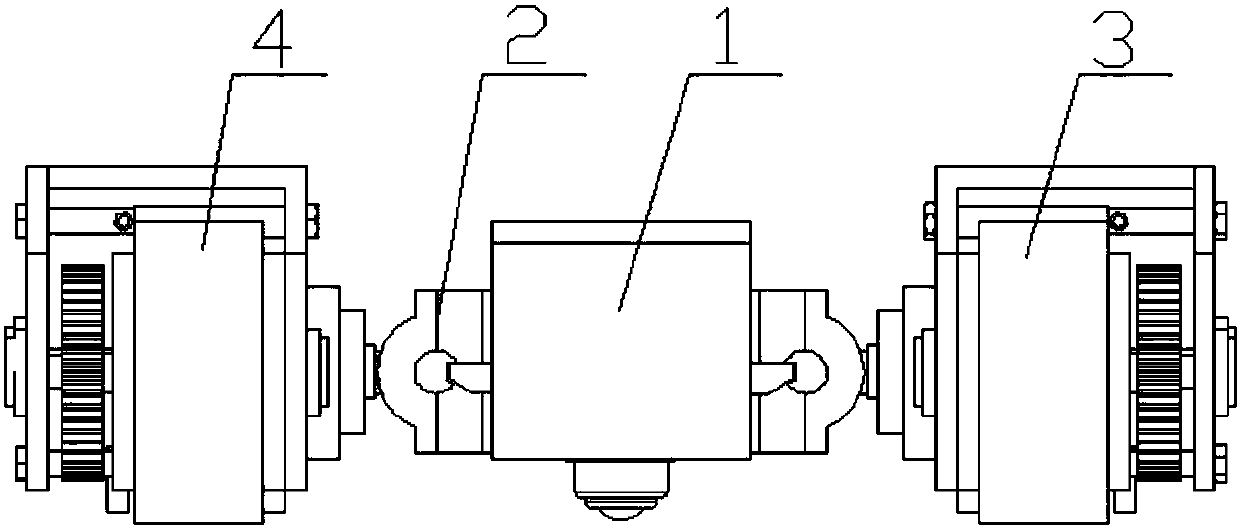

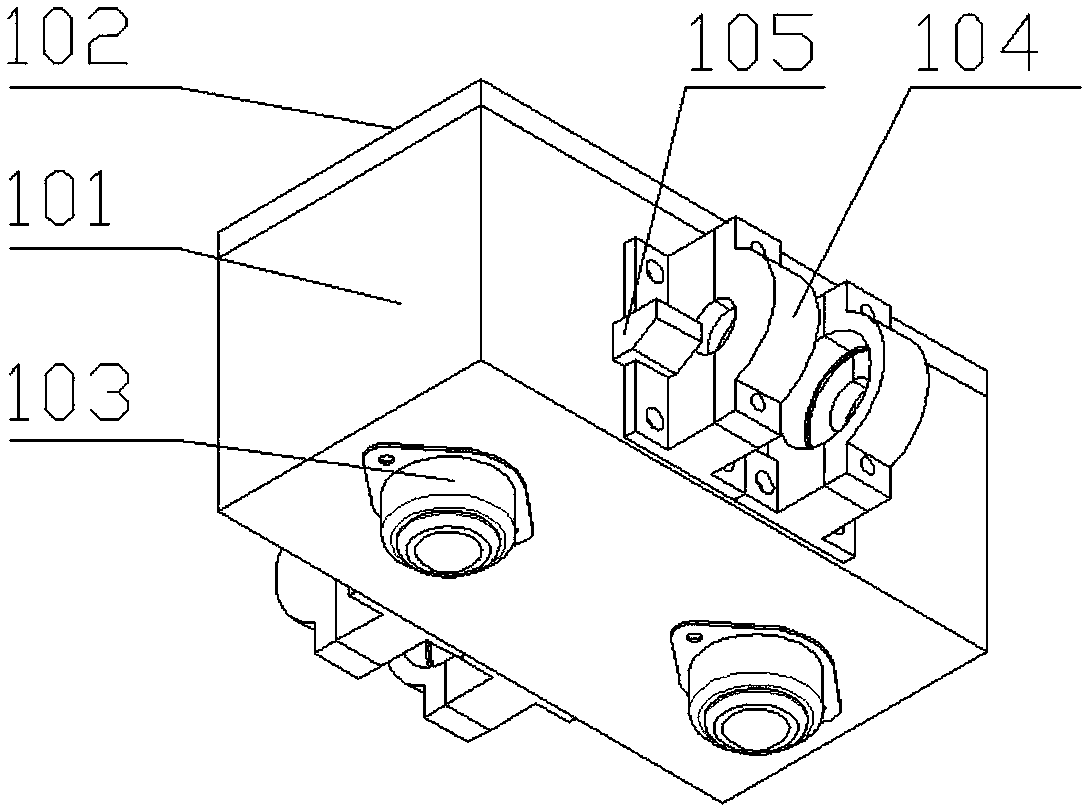

[0032] The present invention is applicable to the wall-climbing operation robot (abbreviation robot, see Figure 1-10 ) includes two mutually independent mobile modules and a vehicle body intermediate platform 1, the two mutually independent mobile modules are identical in structure, arranged symmetrically with the vehicle body intermediate platform 1 as the center, and pass through the two-degree-of-freedom The limit connection joint 2 is connected with the middle platform 1 of the vehicle body, and the two mutually independent mobile modules include a right mobile module 3 and a left mobile module 4, and each mobile module includes a driving structure fixed on the vehicle frame, a transmission structure, Walking structure, tension structure an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com