Modified polyurethane carrier for grafting acrylic acid by ultraviolet and preparation method and application of carrier

A polyurethane and acrylic technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of poor hydrophilic properties of polyurethane carriers, long microbial film hanging time, easy to float, etc. , to achieve the effect of improving anti-pollution ability, improving hydrophilicity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the polyurethane carrier used in following examples is as follows:

[0041] Mix isocyanate and polyester polyol at room temperature according to the ratio of 100:46, put it in a mixer, stir evenly at 800rpm, wait for it to foam and expand and solidify, cut into cubes of 2-3cm, and place Dry in an oven at 60°C for later use. It is required that the specific surface area of the foamed polyurethane foam (that is, the polyurethane carrier) is greater than 1000, and the porosity is greater than 96%.

[0042] The characterization method to the hydrophilic modified polyurethane carrier in the following examples is specifically as follows:

[0043] The contact angle is directly measured and read by an instrument, and the instrument used is a DSA100 contact angle measuring instrument.

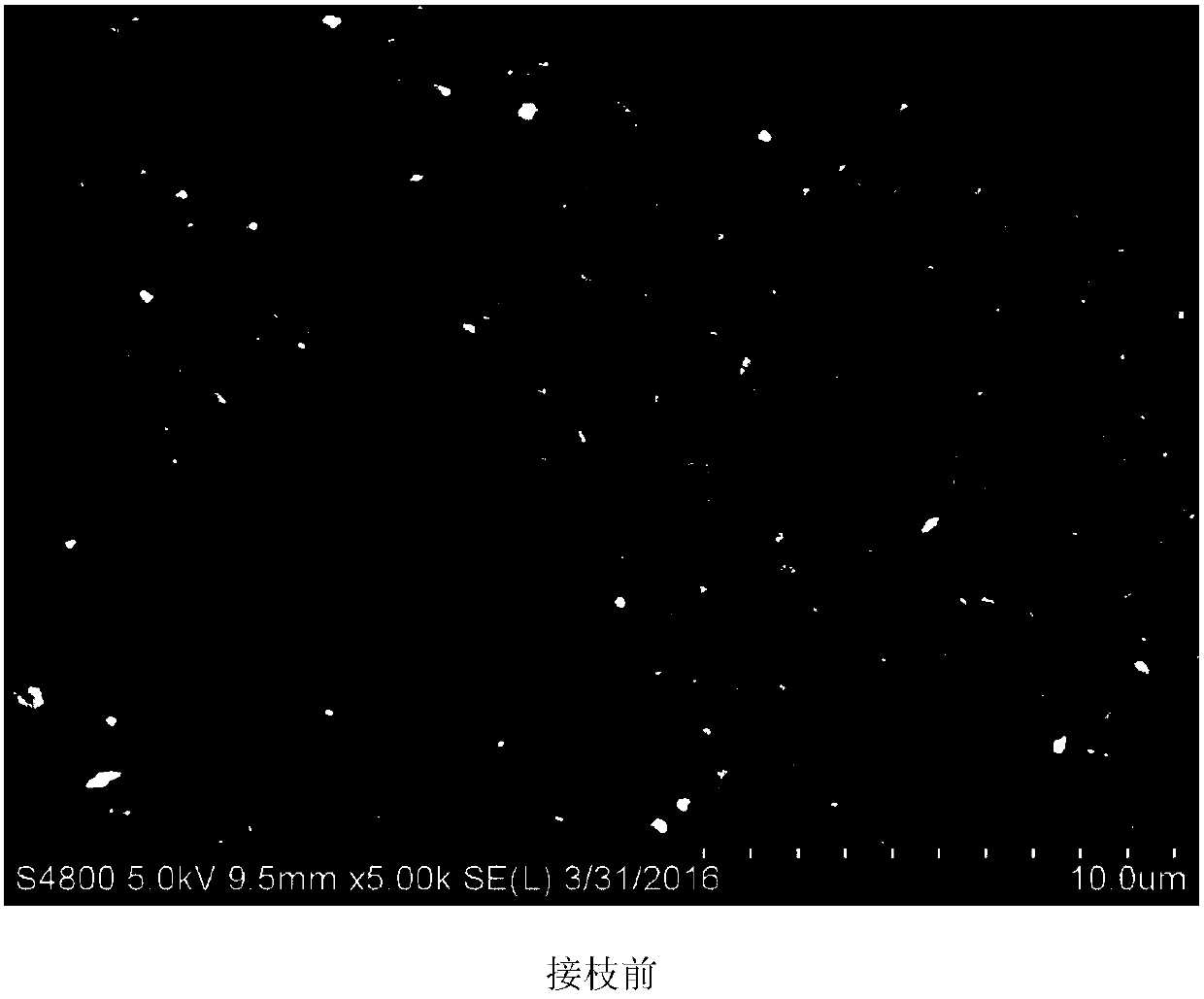

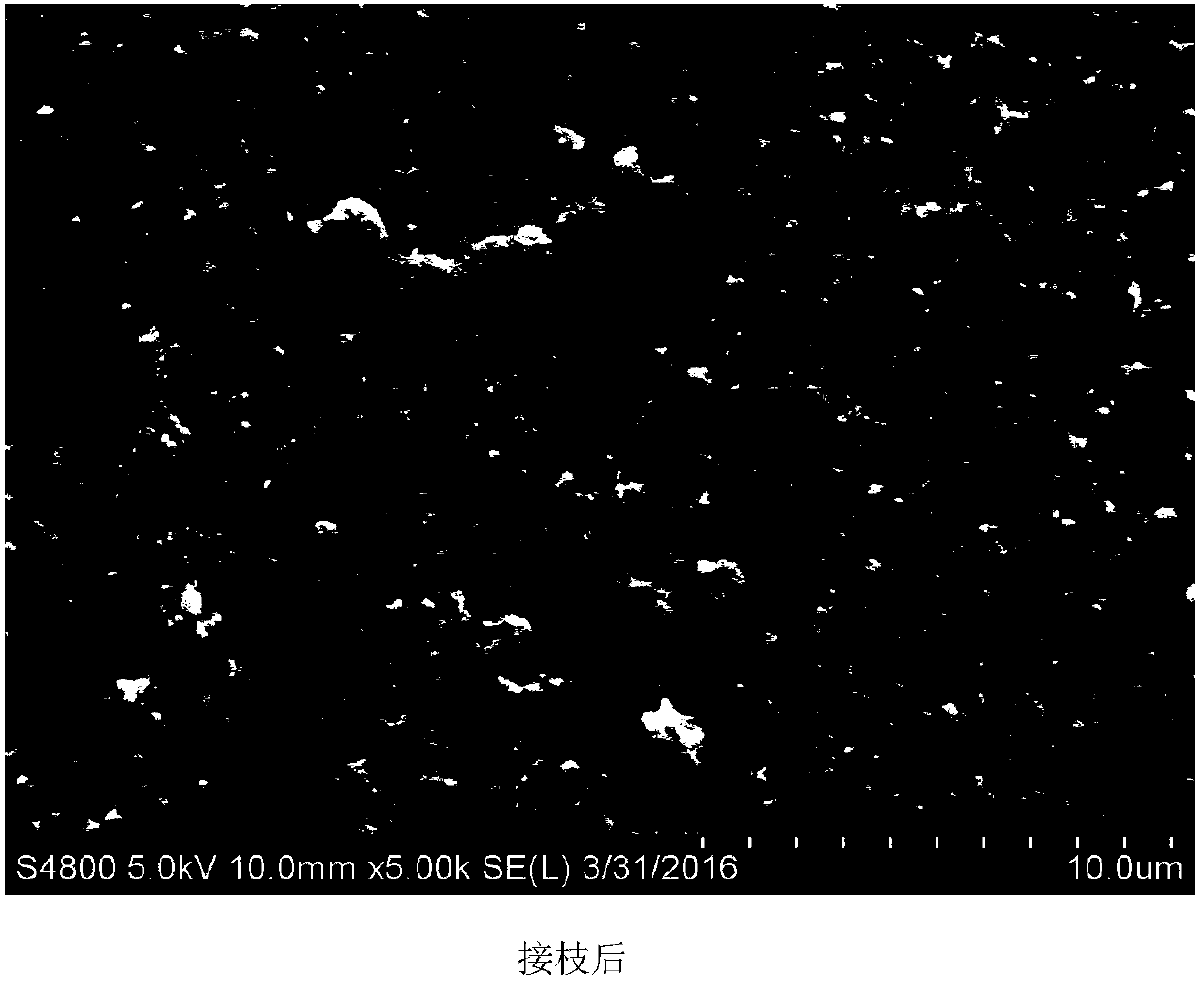

[0044] Electron micrographs were tested with an electron microscope, and the instrument used was a Hitachi S-4800 cold field emission scanning electron microscope. ...

Embodiment 1

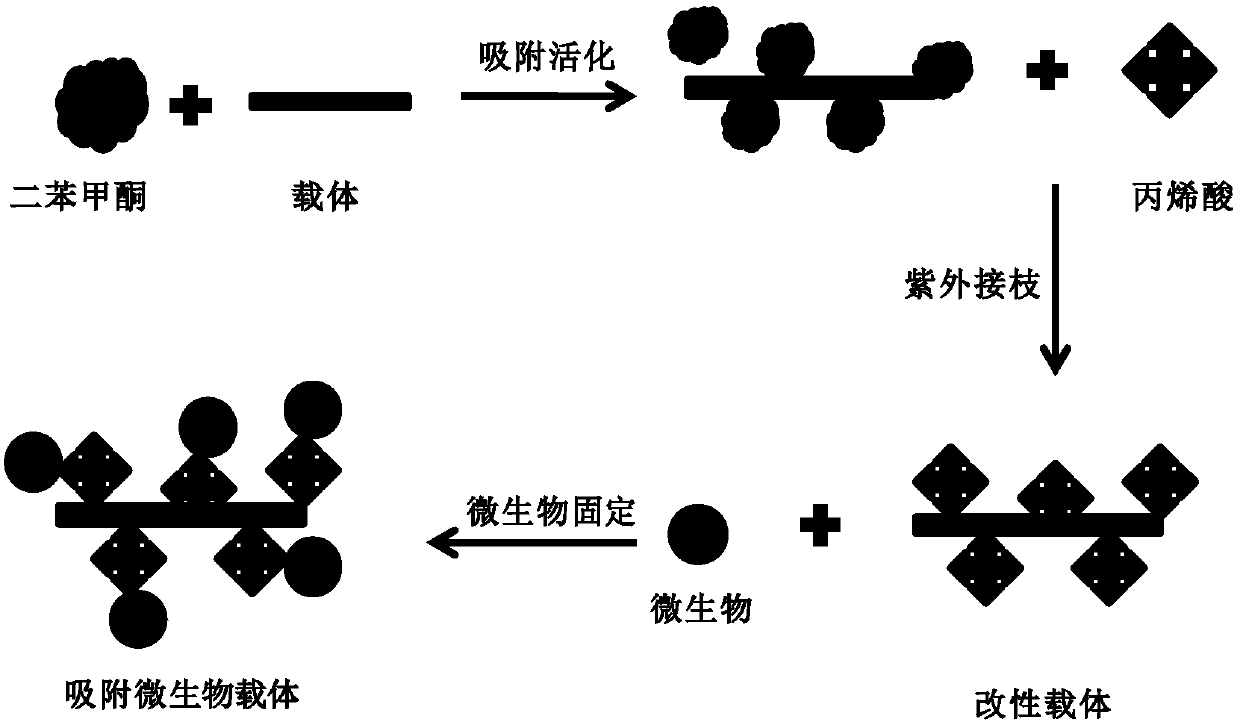

[0050] 1. UV-grafted acrylic modified polyurethane carrier (such as figure 1 shown)

[0051] Step a: immerse a cubic polyurethane carrier with a side length of 2 cm in a methanol solution of 0.2 mol / L benzophenone, take it out after soaking for 2 hours, and let it dry naturally for use;

[0052] Step b: Put the polyurethane carrier treated in step a into the ultraviolet light generating device, immerse it in 15% acrylic acid solution, take it out after 30 minutes of ultraviolet light irradiation, put it in distilled water and wash it clean, and obtain the hydrophilic modified polyurethane carrier.

[0053] 2. Characterization results

[0054]The contact angle of the polyurethane carrier before and after the hydrophilic modification in step 1 was tested, and the results were 116° and 71° respectively. The contact angle of the polyurethane carrier after the hydrophilic modification decreased significantly, and the hydrophilicity improved significantly.

[0055] 3. Immobilizat...

Embodiment 2

[0062] 1. UV-grafted acrylic modified polyurethane carrier

[0063] Step a: immerse a cubic polyurethane carrier with a side length of 3 cm in a 0.5 mol / L ethanol solution of 2,4-dihydroxybenzophenone, take it out after soaking for 1 hour, and let it dry naturally for use;

[0064] Step b: Put the polyurethane carrier treated in step a into the ultraviolet light generating device, immerse it in 20% acrylic acid solution, take it out after 10 minutes of ultraviolet light irradiation, put it in distilled water and wash it clean, and obtain the hydrophilic modified polyurethane carrier.

[0065] 2. Characterization results

[0066] The contact angle of the polyurethane carrier before and after the hydrophilic modification in step 1 was tested, and the results were 118° and 63° respectively. The contact angle of the polyurethane carrier after the hydrophilic modification decreased significantly, and the hydrophilicity improved significantly.

[0067] 3. Immobilization of microor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap