A kind of sealing agent for CTP plate material sealing and using method thereof

A pore sealing agent and pore sealing technology, used in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve the problems of difficult to control the sealing, high energy consumption, coating white spots, etc. , excellent performance, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

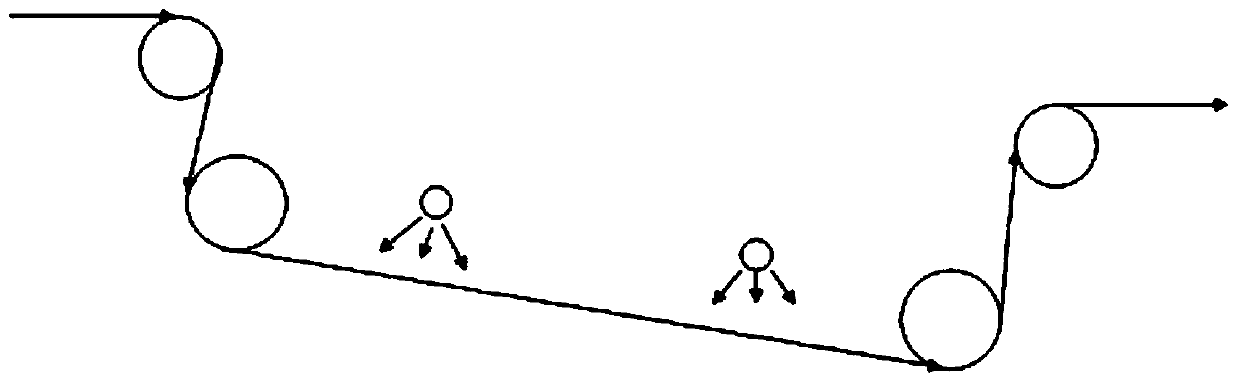

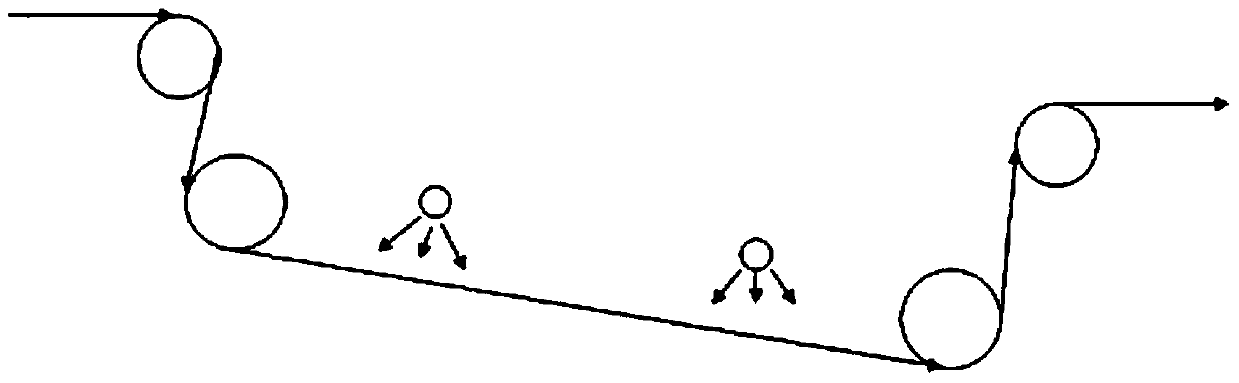

Image

Examples

Embodiment 1

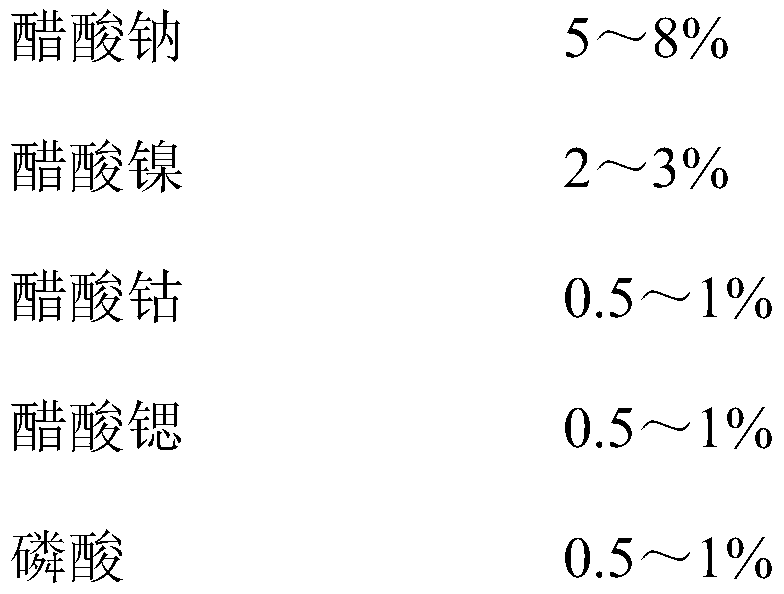

[0022]

[0023] The balance is water, and the pH value of the sealing agent is 4-7.

[0024] Use the sealing agent to spray the anodized aluminum plate at 35°C for 15 seconds, and then wash it with deionized water to complete the sealing treatment of the aluminum plate. Plate making and development of the CTP plate obtained through the sealing treatment And the plates were tested accordingly, and the results are shown in Table 1.

Embodiment 2

[0026]

[0027] The balance is water, and the pH value of the sealing agent is 4-7.

[0028] Use the sealing agent to spray the anodized aluminum plate at 40°C for 12 seconds, and then wash it with deionized water to complete the sealing treatment of the aluminum plate. Plate making and development of the CTP plate obtained through the sealing treatment And the plates were tested accordingly, and the results are shown in Table 1.

Embodiment 3

[0030]

[0031] The balance is water, and the pH value of the sealing agent is 4-7.

[0032] Use the sealing agent to spray the anodized aluminum plate at 55°C for 10 seconds, and then wash it with deionized water to complete the sealing treatment of the aluminum plate. Plate making and developing of the CTP plate obtained through the sealing treatment And the plates were tested accordingly, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com