End cover of servo oscillating type hydraulic cylinder

A hydraulic cylinder, swing-type technology, applied in the field of end caps of servo swing hydraulic cylinders, to achieve the effect of preventing contact and improving dynamic control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

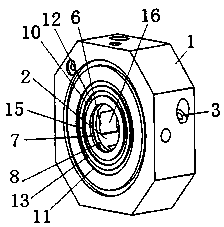

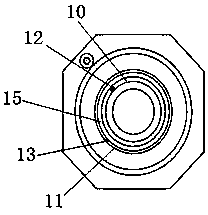

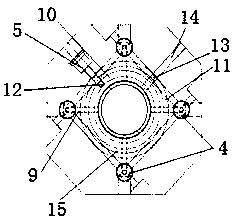

[0018] combine Figure 1 to Figure 4 As shown, the end cover of a servo swing hydraulic cylinder in the present invention includes a cover body 1 and a shaft hole 2 opened in the middle of the cover body. The outer surface of the cover body 1 is provided with four high-pressure oil source oil inlet holes 3, There are 4 radial bearing restrictors 4 and 1 thrust bearing restrictor 5 installed in the cover body, and 4 radial bearing oil outlet holes 6 and 4 radial bearing restrictors are opened in the shaft hole 2 The oil outlet end of 4 is connected with four radial bearing oil outlet holes 6, and a radial bearing oil drain groove 7 is set between the end face of the cover body 1 and the shaft hole 2, and a radial bearing oil drain hole is opened in the radial bearing oil drain groove 7 8. The radial bearing oil drain hole 8 is connected with the radial bearing oil drain line 9. The end surface of the cover body 1 is provided with a thrust bearing oil outlet groove 10 and a thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com