Whole vehicle drive-by-wire system and control method for unmanned vehicle

A technology for unmanned vehicles and vehicle lines, which is applied to vehicle components, braking safety systems, circuits or fluid pipelines, etc., can solve problems such as unmanned heavy-duty vehicles, and improve dynamic control capabilities and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

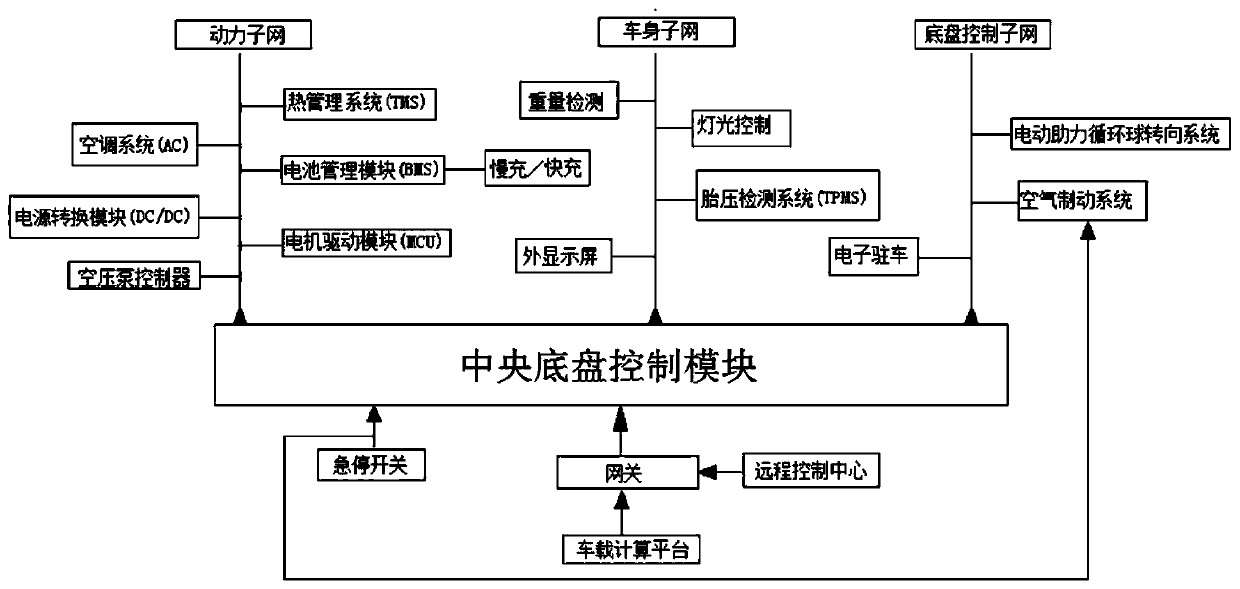

[0022] refer to figure 1 As shown, this embodiment is a vehicle-by-wire control system for an unmanned vehicle, including a central chassis control module, an emergency stop switch connected to the central chassis control module, and an air brake system connected to the emergency stop switch;

[0023] The central chassis control module is connected to the power subnetwork used to execute the electronic braking of the vehicle, the air brake system used to implement the mechanical brake of the vehicle, and the parking system for the electronic braking of the vehicle or the parking system when the mechanical brake fails through the CAN bus interface. Braking electronic parking system.

[0024] The power subnet includes air conditioning system, power conversion module, air compressor controller, thermal management system (TMS), battery management module (BMS), and motor drive module (MCU). The battery management module is connected with a fast charging / slow charging module to sup...

Embodiment 2

[0040] This embodiment is a vehicle-by-wire control method for an unmanned vehicle, comprising the following steps:

[0041] 1) The emergency stop switch is connected to the central chassis control module. When the vehicle is out of control, the emergency stop switch is manually operated. After the central chassis control module detects the emergency stop information of the emergency stop switch, it sends a parking command;

[0042] 2) The central chassis control module is connected to the power subnetwork, air brake system and electronic parking system through the CAN bus interface. After the power subnetwork receives the parking command, it executes the electronic braking of the vehicle; after the air brake system receives the parking command, it Execution of the mechanical brakes of the vehicle;

[0043] 3) When the electronic brake or mechanical brake fails, or when the electronic parking system detects that the vehicle speed drops to zero; the electronic parking system ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com