A vane type servo swing hydraulic cylinder and its mechanical equipment

A technology for swinging hydraulic cylinders and mechanical equipment, applied in the direction of fluid pressure actuating devices, etc., can solve problems such as increased wear, increased leakage, and increased leakage, and achieves the effect of preventing contact and improving dynamic control performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

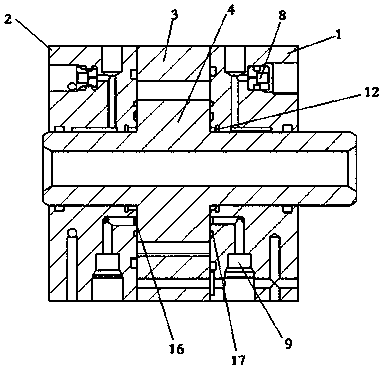

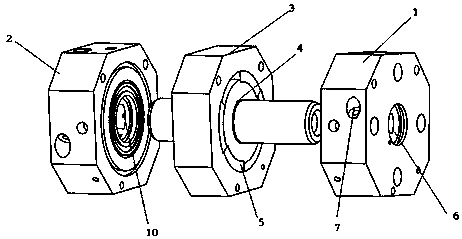

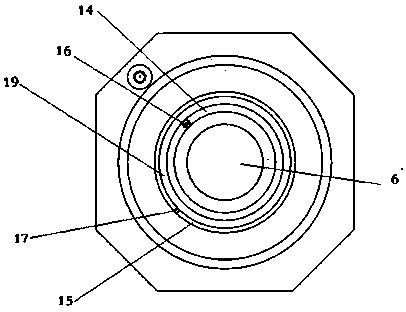

[0025] combine Figure 1 to Figure 5As shown, a vane-type servo swing hydraulic cylinder of the present invention and its mechanical equipment include a front end cover 1, a rear end cover 2, a stator 3 and a rotor 4, the stator and the rotor are assembled between the front end cover and the rear end cover, The rotor is placed inside the stator. There are four oil chambers 5 between the blades of the rotor and the stator. The front end cover 1 and the rear end cover 2 are provided with shaft holes 6. A high-pressure oil source oil inlet hole 7, four radial bearing restrictors 8 and one thrust bearing restrictor 9 are installed in the front end cover 1 and the rear end cover 2, and the shaft holes of the front end cover 1 and the rear end cover 2 is provided with 4 radial bearing oil outlet holes 10, the oil outlet ends of the 4 radial bearing throttles 8 are connected to 4 radial bearing oil outlet holes 10, the end faces and shafts of the front end cover 1 and the rear end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com