Pipe-hanger support

A technology for supporting hangers and pipes is applied in the field of supporting and hanging frames, which can solve the problems of poor shock absorption performance, complicated installation and complex structure, and achieve the effects of improving shock absorption performance, prolonging service life and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

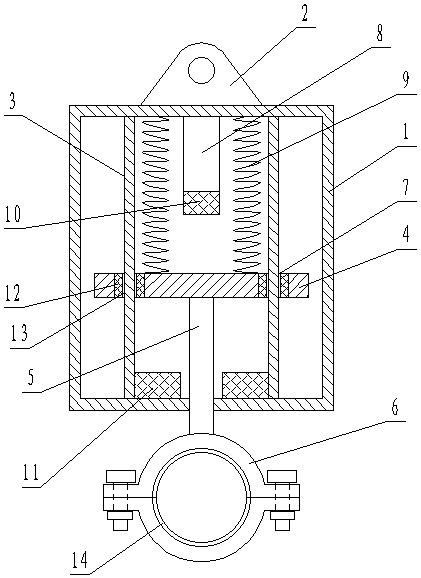

[0017] Such as figure 1 As shown, a pipe support and hanger includes a housing 1, the top of the housing 1 is provided with a hanging plate 2, and the housing 1 is provided with a guide column 33 and a spring pressure plate 4, and the bottom of the spring pressure plate 4 is connected to the suspension rod 5 , the bottom end of the boom 5 is connected to the pipe clamp 6, the guide column 33 has two and is respectively located on the left and right sides of the boom 5, and the two sides of the spring pressure plate 4 are provided with the guide column 33 Corresponding to the guide hole 7, a limit rod 8 is also provided in the housing 1, and the limit rod 8 is located between two guide columns 33, and the top of the limit rod 8 is fixed on the top of the housing 1. On the inner wall, the bottom end of the limiting rod 8 is provided with a shock absor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap