90-degree elbow for buffering water hammer force

A technology of water hammer and elbows, applied in the field of 90° elbows, can solve problems such as undiscovered, and achieve the effects of low cost, avoiding vicious damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

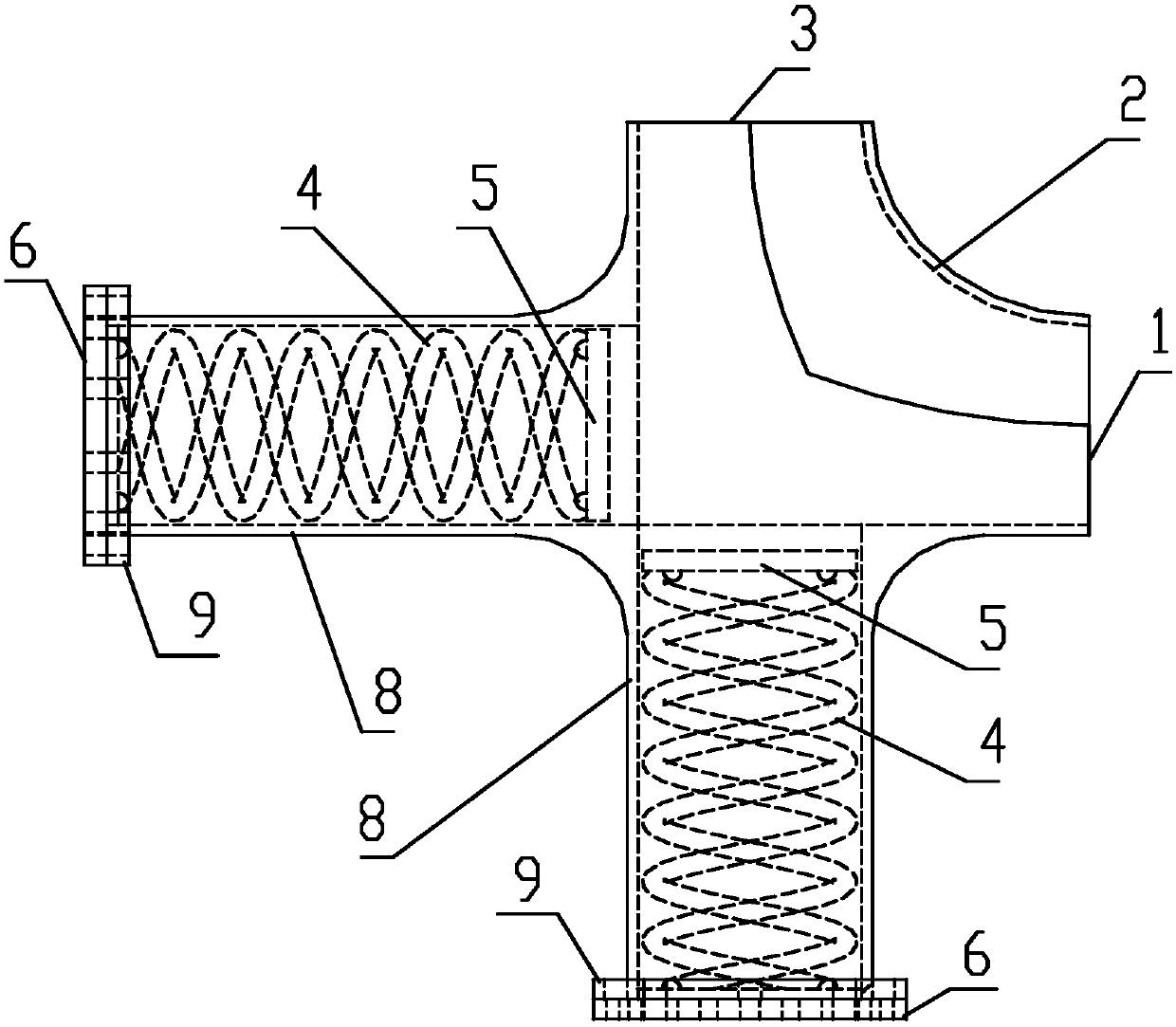

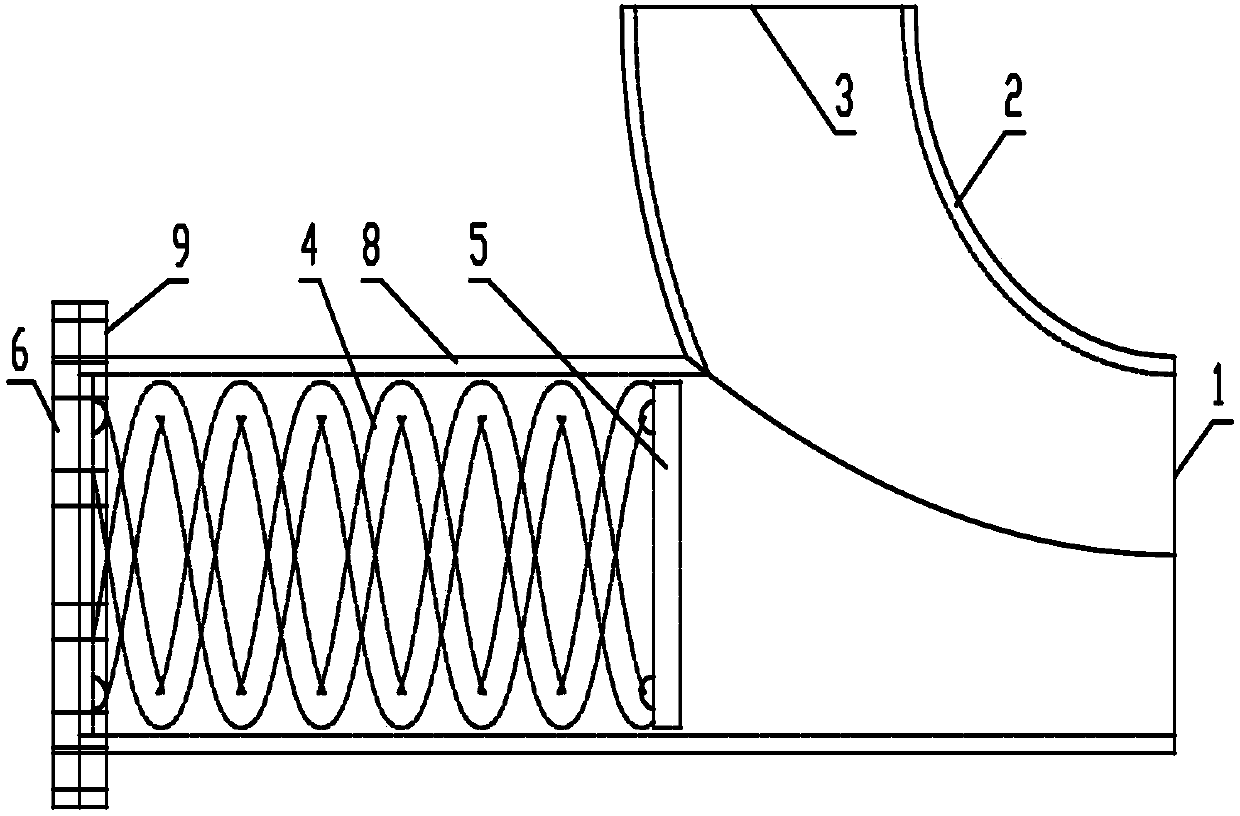

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

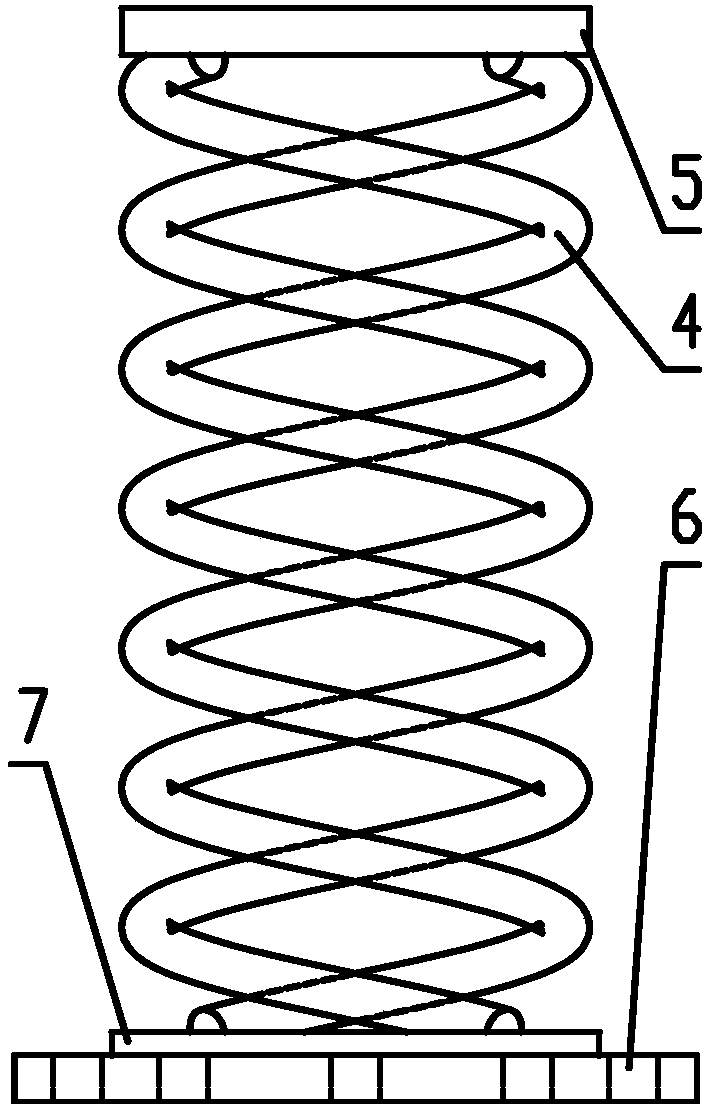

[0016] figure 1 is a structural schematic diagram of an embodiment of the present invention, consisting of figure 1 and image 3 It can be seen that the 90° elbow for buffering the water hammer force is mainly composed of a 90° elbow 2 and two buffer pipes, and the buffer pipe is mainly composed of a tubular cylinder 8 with a flange 9 at one end, a flange cover 6, a spring base 7, The spring 4 and the pressure plate 5 are composed. The spring base 7 is welded on the side of the flange cover 6 facing the flange 9; the spring 4 is two, forming a double helix structure; one end of the double helix structure spring 4 is welded to the spring base 7, and the other end is connected to the pressure plate 5 Phase welding. Both the flange cover 6 and the pressure plate 5 are perpendicular to the axis of the spring 4, the flange cover 6 at one end of the spring 4 matches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com