Negative-pressure liquid cooling system and control method thereof

A control method and technology of cooling system, applied in the direction of electric fluid pressure control, electrical components, electrical equipment structural parts, etc., can solve problems such as coolant leakage, reduce the risk of system leakage, avoid potential safety hazards, avoid Effect of coolant leakage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

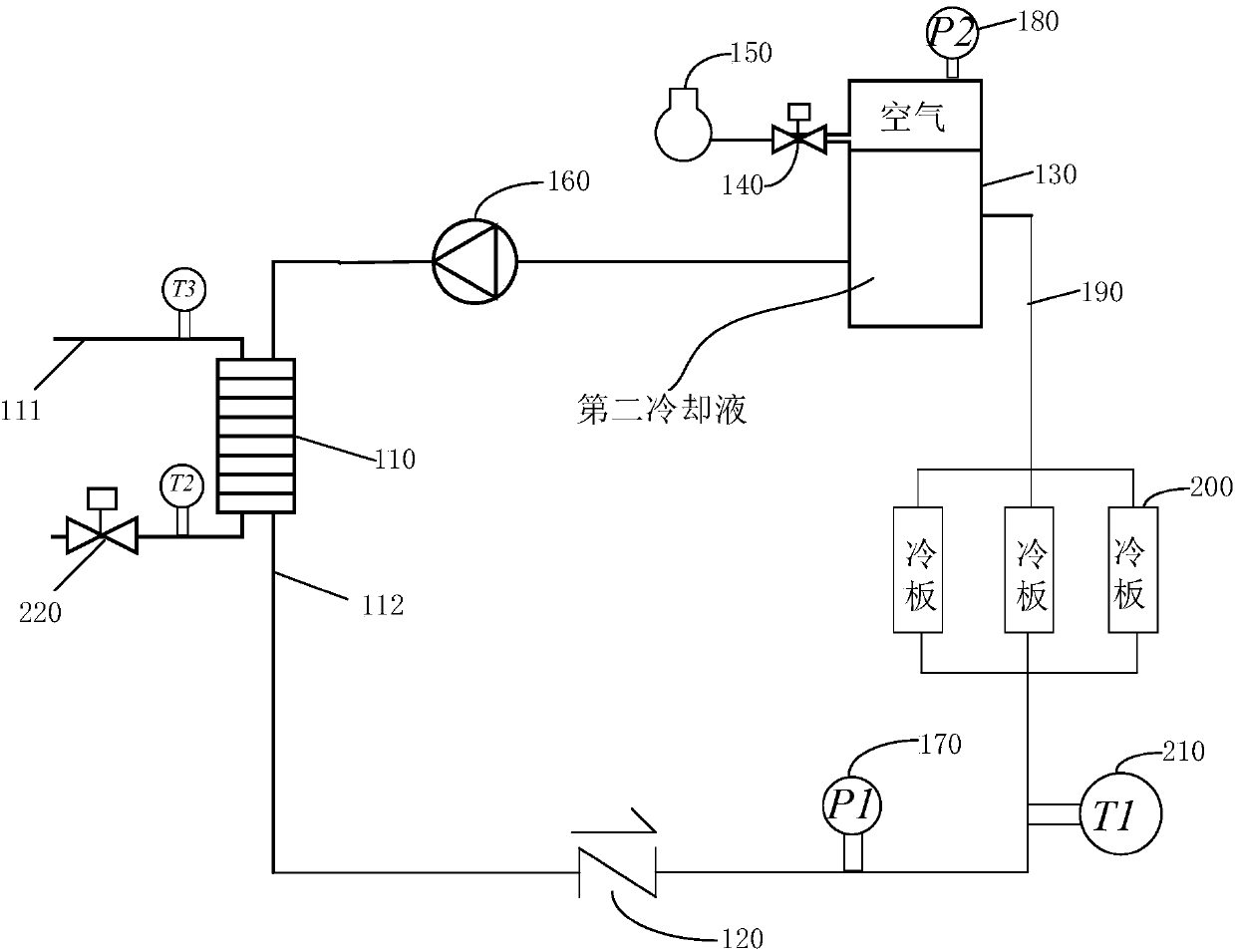

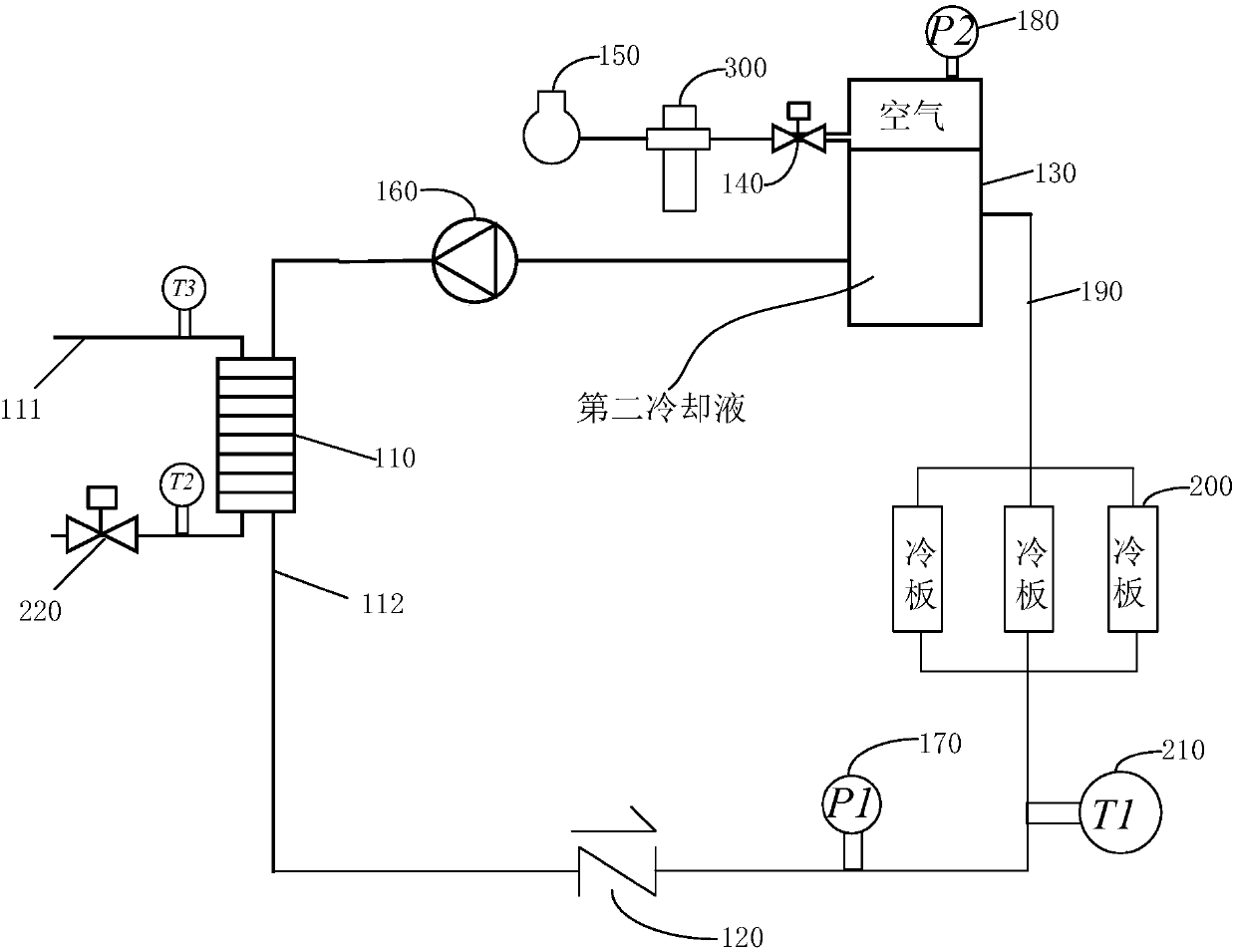

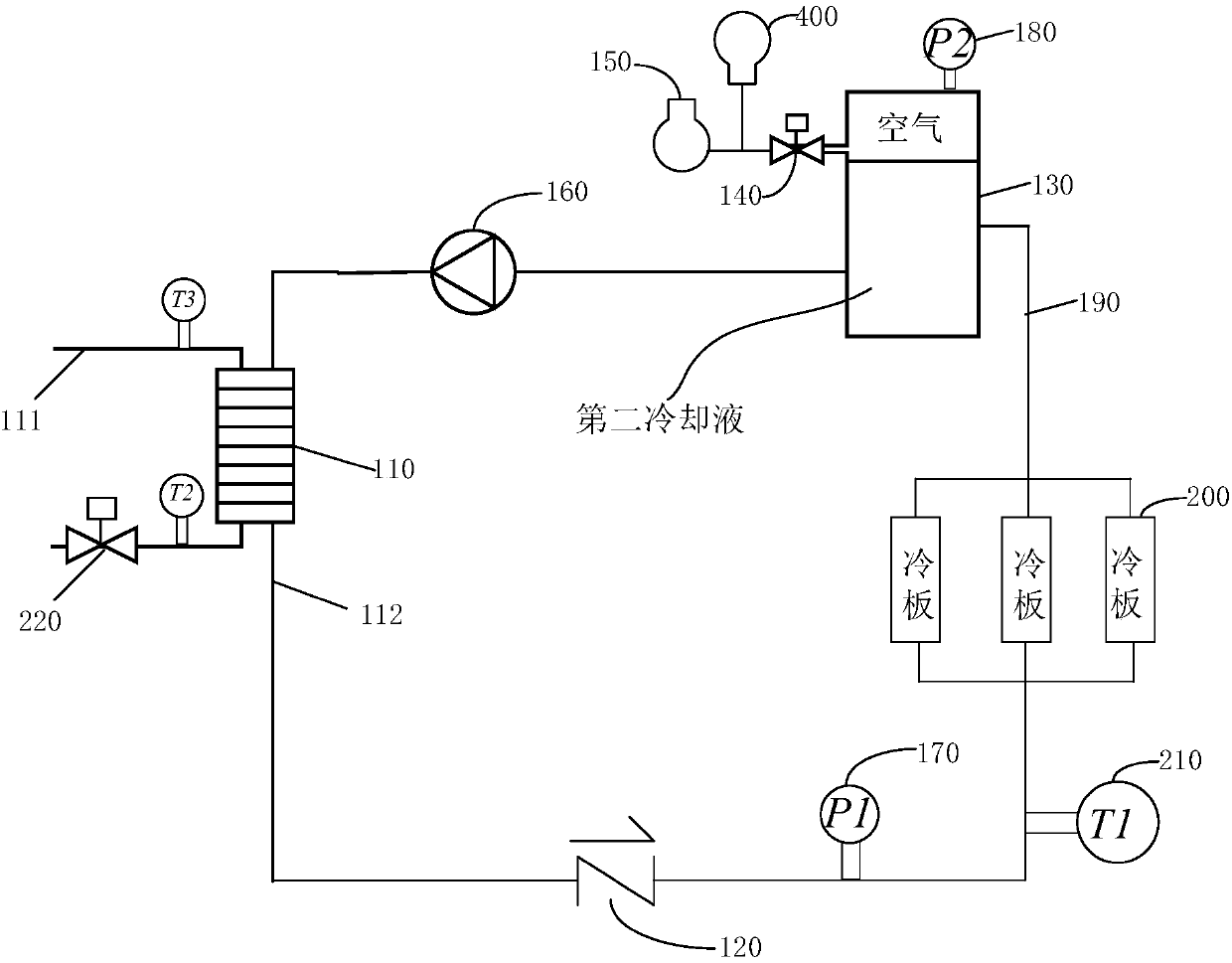

[0041] The traditional liquid cooling system is usually a positive pressure system, that is, the liquid pressure in the pipeline is greater than the ambient pressure outside the pipeline. In this way, when the pipeline between the inlet and the outlet of the cold plate is perforated, the liquid in the pipeline will leak from the perforation to the electronic equipment to be cooled, which may cause damage to the electronic equipment to be cooled or potential safety hazards. Part of the negative pressure system is also adopted, but the traditional negative pressure system uses a constant pressure difference between the inlet and outlet of the cold plate to control the flow in the system. The system can maintain the negative pressure in the system during normal operation, but when the cold plate is between the inlet and the outlet When the pipe is perforated, the pressure at the outlet of the cold plate rises. If the flow is still controlled according to the constant pressure diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com