Drawer structure of switch cabinet

A switchgear and drawer technology, applied in pull-out switchgear, switchgear, switchgear components, etc., can solve problems such as hidden dangers, existing safety, and shortening the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

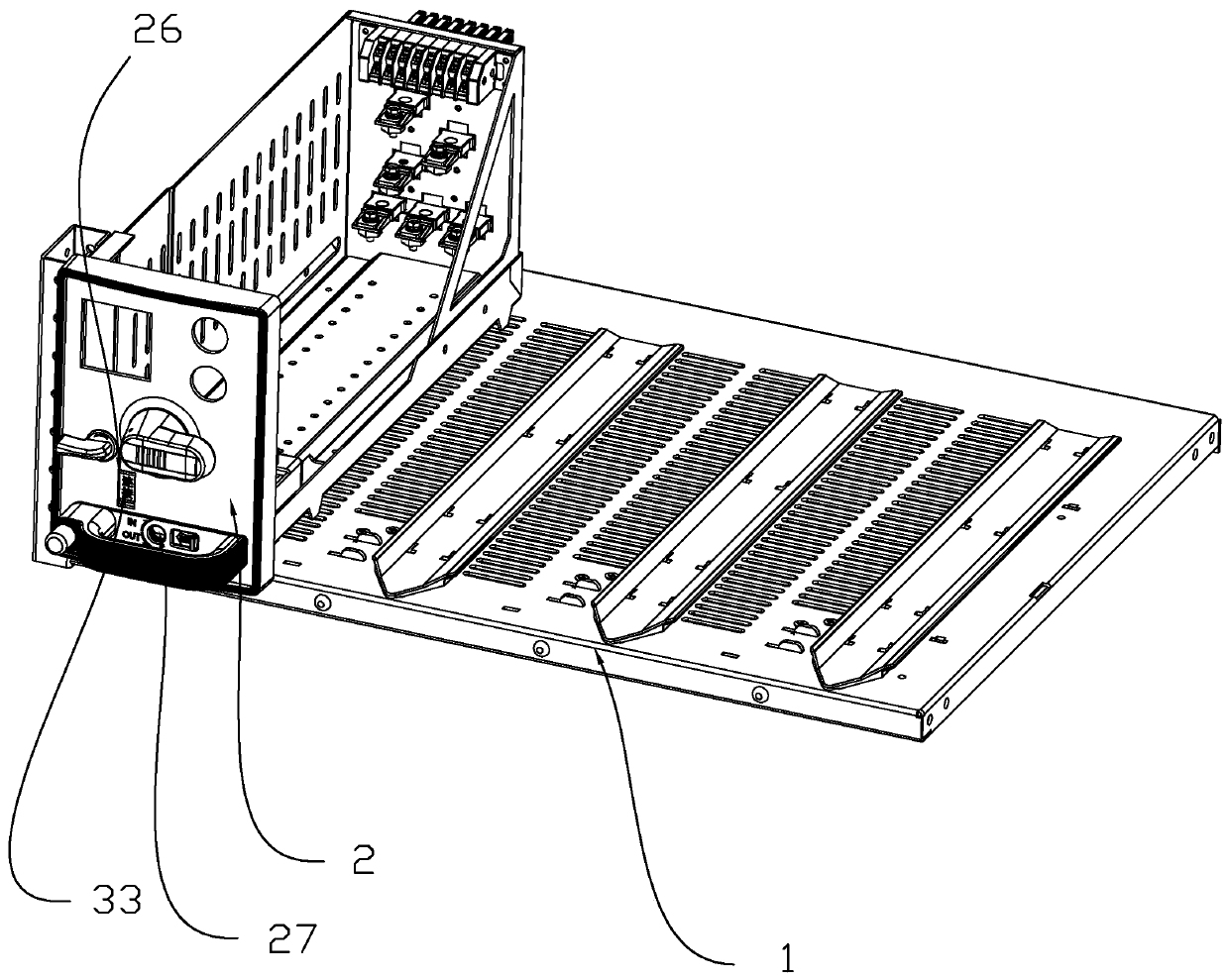

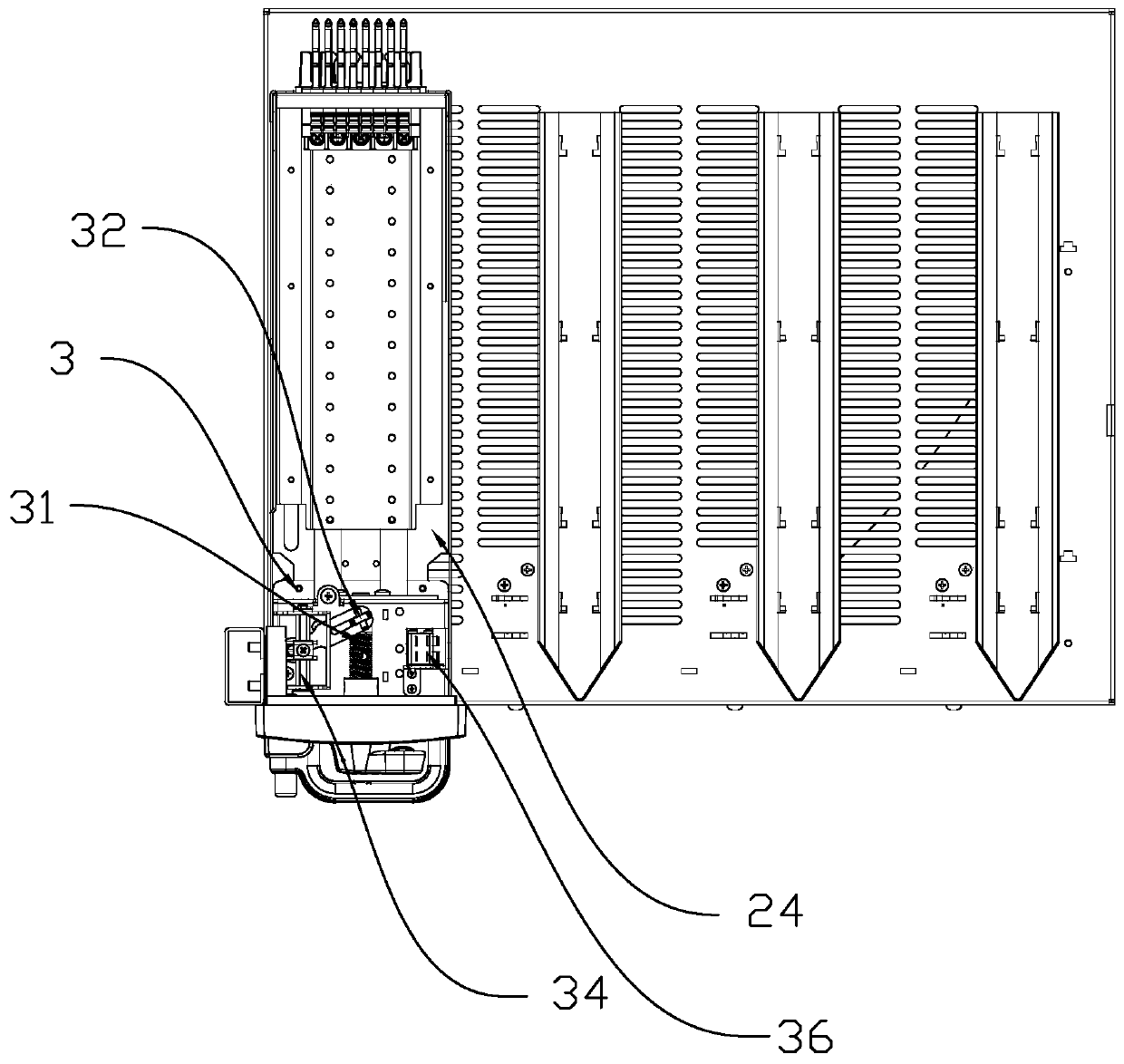

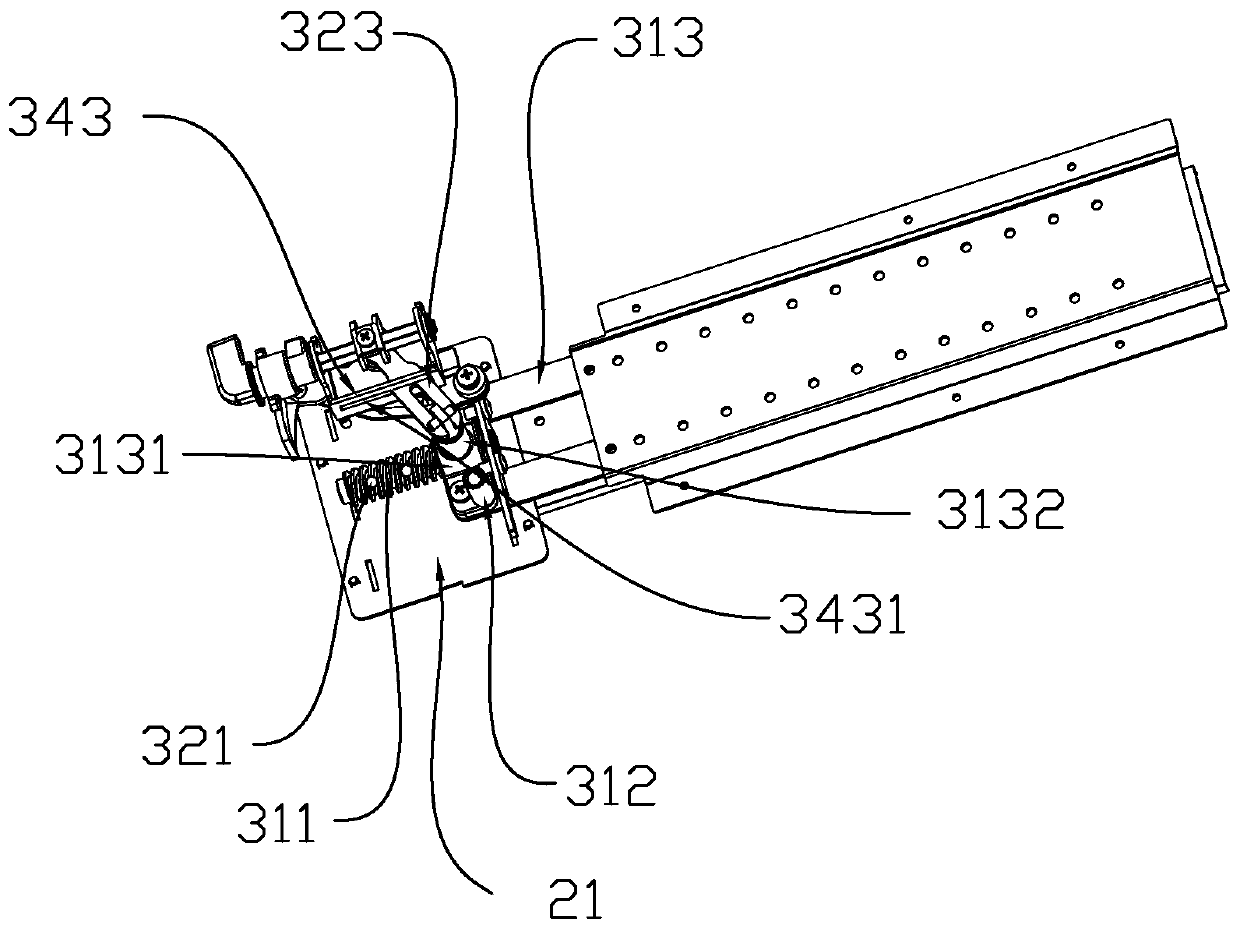

[0039] Specific embodiments of the present invention such as Figure 1-13As shown, a drawer structure of a switchgear includes a cabinet body 1 and a drawer body 2 arranged in the cabinet body 1. An operating assembly 3 is arranged in the drawer body 2. The operating assembly 3 includes a pushing mechanism 31 and a locking mechanism 32. And the display mechanism 33, the propulsion mechanism 31 includes the rotating screw rod 311, the contact push block 312 and the threaded contact push plate 313 arranged in the drawer body 2, the contact push block 312 and the contact push plate 313 are fixed or integrated Set, the rotating screw rod 311 is rotated and arranged in the drawer body 2, the rotating screw rod 311 is threaded with the contact push plate 313, the rotating screw rod 311 rotates to drive the contact push plate 313 and the contact push block 312 to move, and the drawer body 2 is provided with a The handle that drives the rotating screw 311 to rotate. The locking mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com