Denture molding flask having check valve installed therein and method for manufacturing denture prosthesis using denture molding flask made of heterogenous materials

A technology of heterogeneous materials and auxiliary materials, applied in functional valve types, dentures, dentistry, etc., can solve problems such as long manufacturing time, low work efficiency, and distortion of denture auxiliary materials, and achieve easy wearing, good quality, and preventive products deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

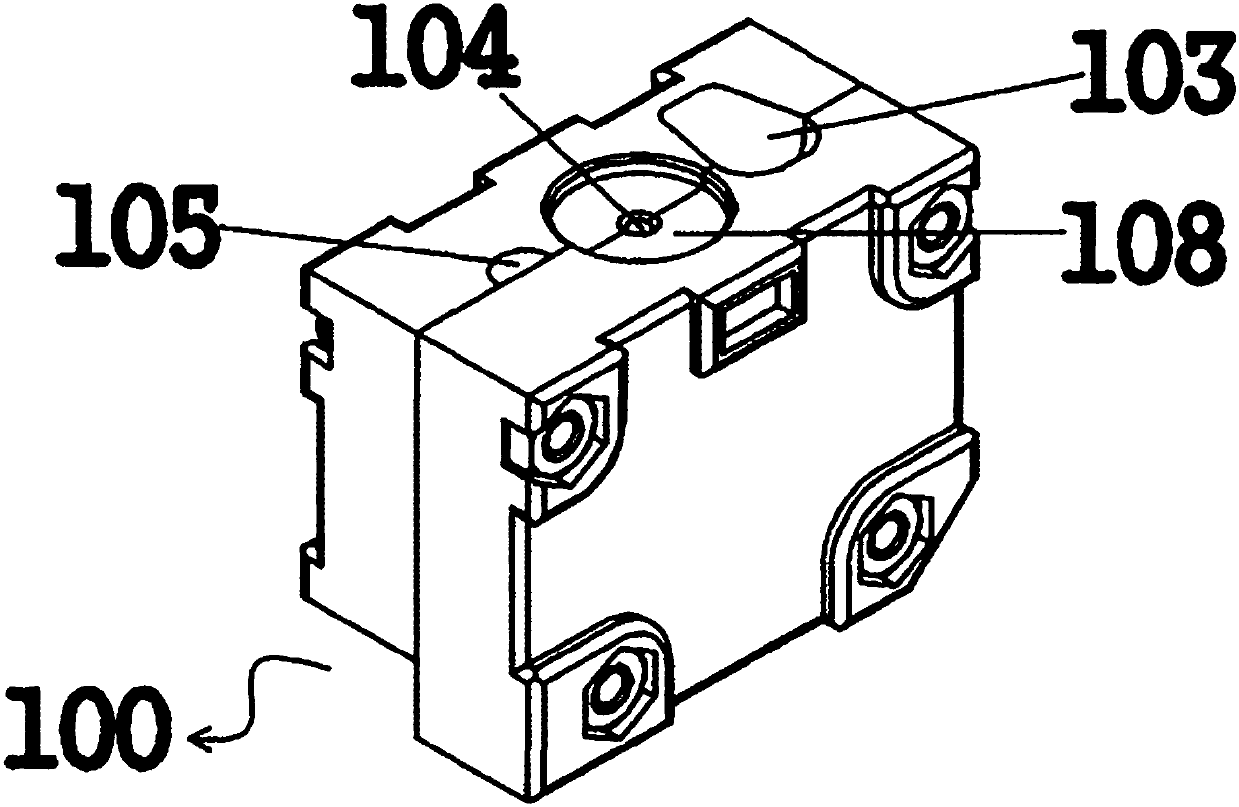

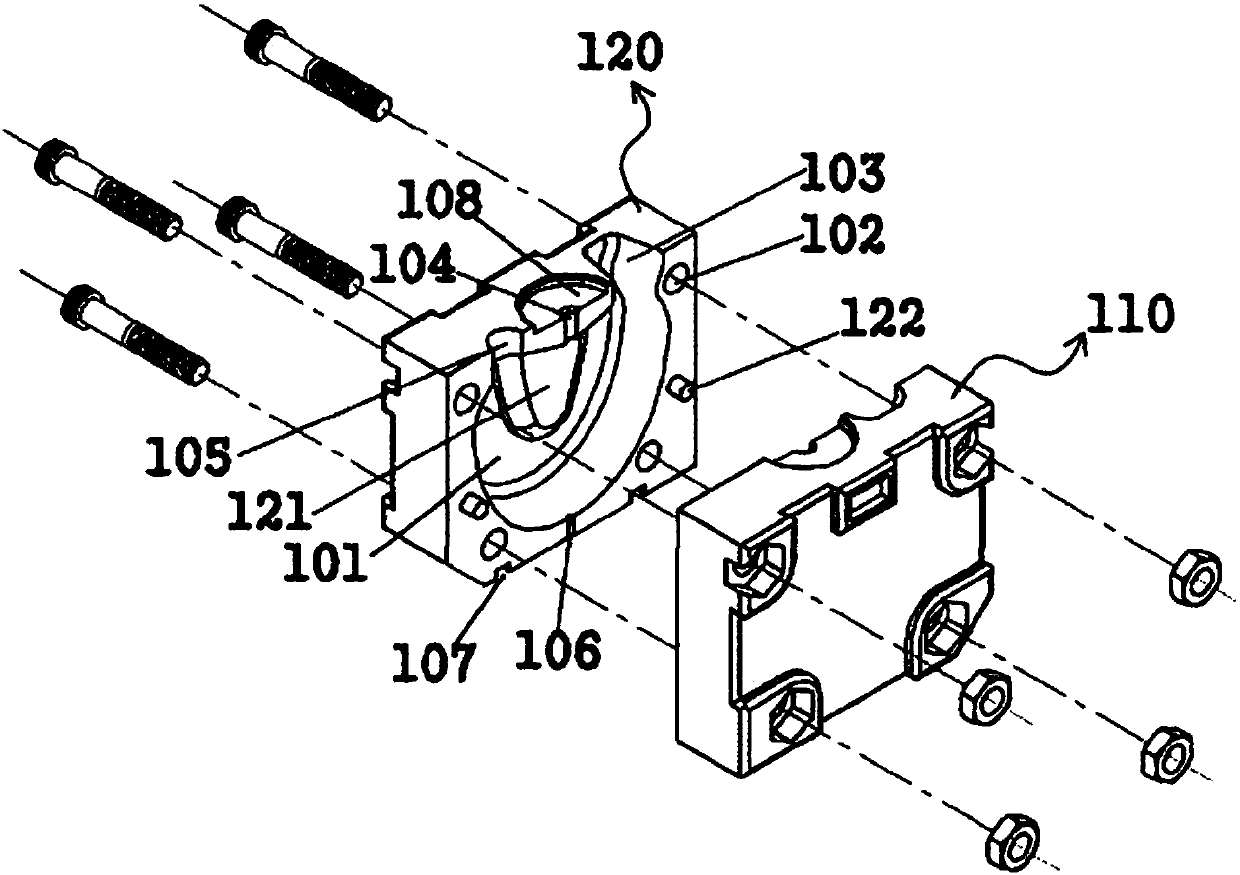

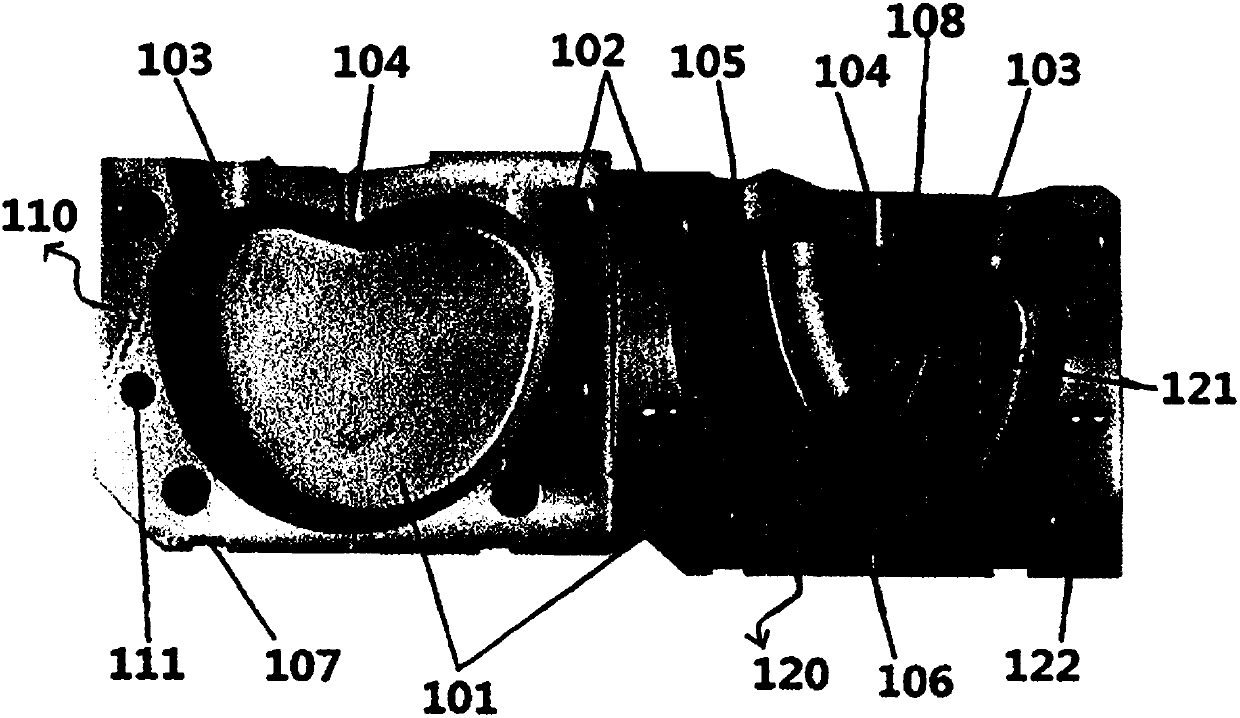

[0043] The present invention relates to a method of manufacturing denture aids using denture molding boxes of heterogeneous materials. As far as denture molding boxes of heterogeneous materials are concerned, they are used to make denture aids through left and right main bodies. 110, 120 formed by the combination, the resin injection port 104 for injecting resin is formed in the upper joint part where the left and right main bodies 110, 120 are combined, and the investment material injection port 103 for injecting gypsum as the investment material is formed. Spaces are formed inside the left and right main bodies 110 and 120 at a certain distance from the resin injection port 104, so that after the wax denture base is inserted into the space, the embedding The material injection port 103 injects the investment material, and when the denture base and the investment material made of wax are inserted into the hollow part 101 and heated, the melted wax is discharged, and the wax di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com