Automatic tillage mechanical arm

A robotic arm and automatic technology, applied in the field of tillage robots, can solve the problems of uneven planting, depth, time and width of agricultural land that cannot be accurately controlled, and achieve better results, simple uneven planting, avoid failure and high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

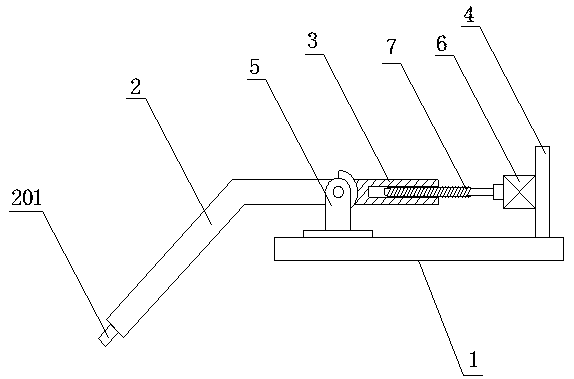

[0035] Option One:

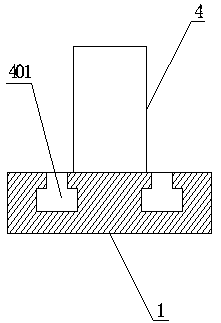

[0036] The telescopic mechanism includes a hydraulic telescopic rod and a second motor 6, one end of the hydraulic telescopic rod is connected with the second end of the arm 2 3, and the other end is connected with the second motor 6, and the second motor 6 is installed on the baffle plate 4.

[0037] Option II:

[0038] Telescoping mechanism comprises screw mandrel 7 and second motor 6, and described arm two 3 is provided with the threaded hole that matches with screw mandrel 7, and screw mandrel 7 one end is installed in the threaded hole and the other end is connected with second motor 6, and second motor ( 6) Installed on the baffle 4. ,

[0039] In order to automatically control the first motor 8 and the second motor 6, the base 1 is provided with a control switch for controlling the first motor 8 and the second motor 6.

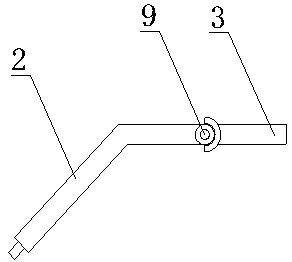

[0040] Finally, in order to conform to the actual operation, the first arm 2 is preferably designed as an arc or "L" shape, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com