Low-temperature combustor

A low-temperature combustion and high-temperature-resistant technology, which is applied in the field of electronic cigarettes, can solve the problems of complicated filter making process, inability to use raw materials, and ineffective effects, and achieve the effects of saving production costs, increasing speed, and reducing harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

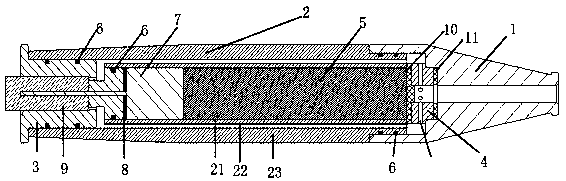

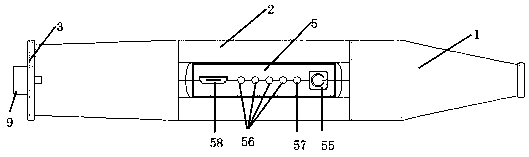

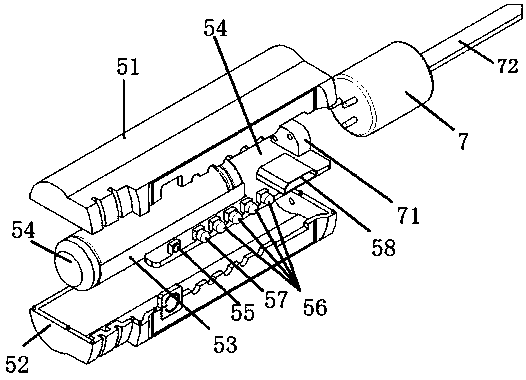

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] As shown in the figure, a low-temperature burner includes a suction nozzle 1, a smoke chamber 2, a pipe 3, a heating head 7 and a control system 5. It is characterized in that the smoke chamber 2 is provided with a control system 5 installation groove, so The heating head 7 described above is installed at one end of the control system 5, the heating head 7 and the control system 5 are installed in the smoke chamber 2, the suction nozzle 1 is clipped on the smoke chamber 2, and the heating head 7 and the control system 5 are locked in the smoke chamber 2 Inside, the nozzle core 4 is installed at the junction between the nozzle 1 and the smoke chamber 2, the nozzle 1 is provided with a vent hole A, the nozzle core 4 is provided with a circular hole in the middle of the same size as the vent hole A, and the nozzle core 4 There is a ventilation hole B that is the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com