Method and system for controlling temperature of engine coolant

A technology of engine coolant and temperature control method, which is applied in the direction of engine cooling, coolant flow control, engine components, etc., can solve the problems of water temperature shock, difference, and long response time of the execution unit, so as to achieve efficient water temperature control and fuel Low economy, avoid high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

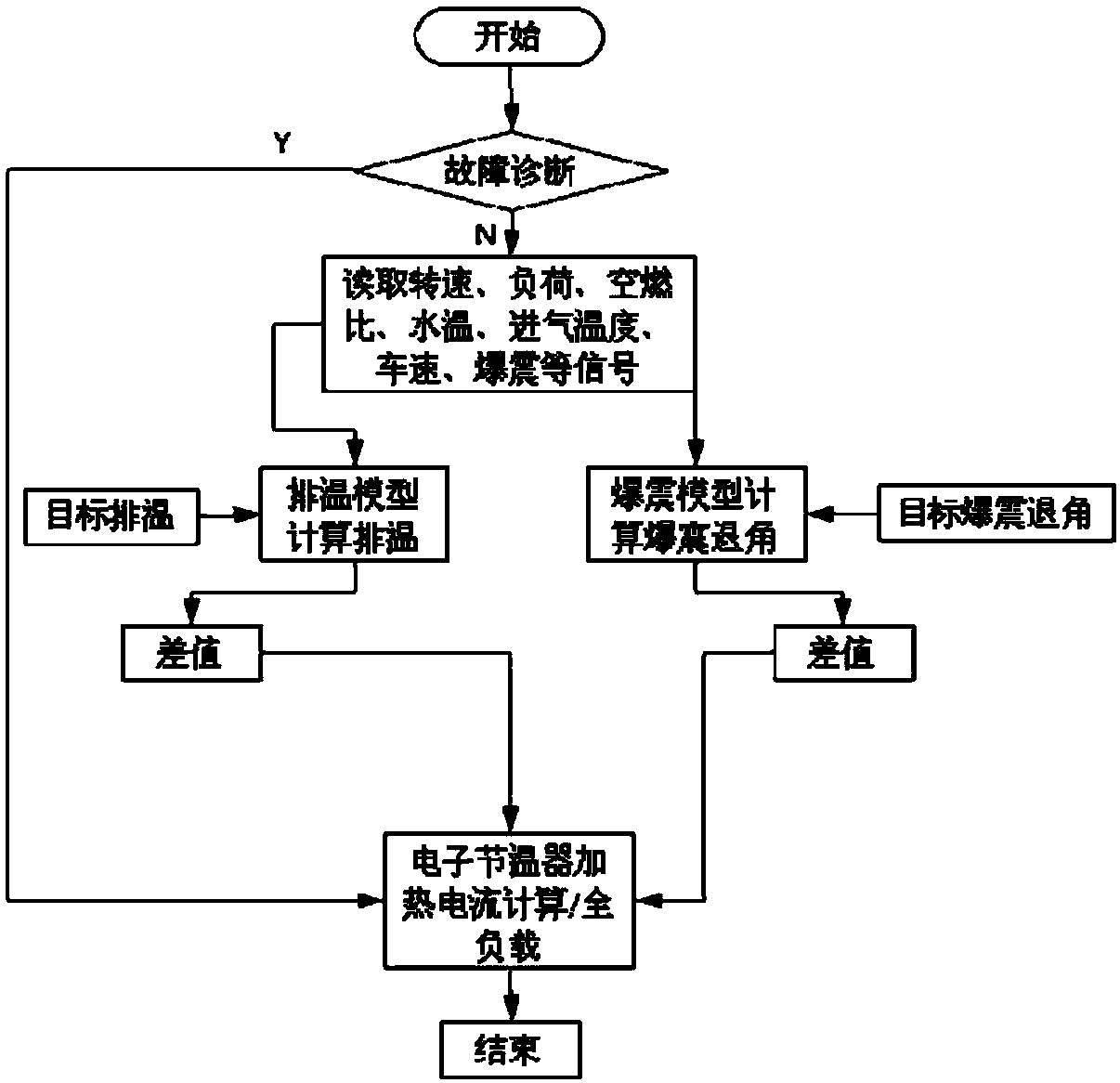

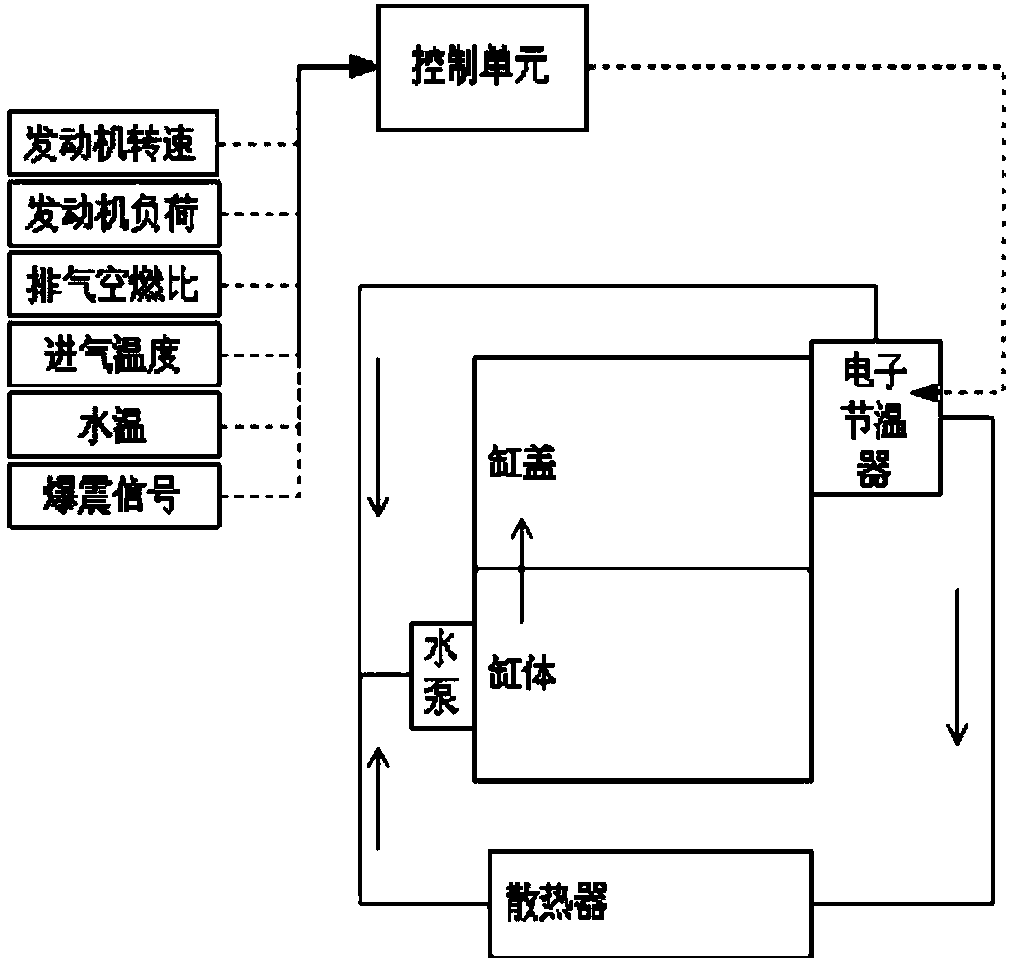

[0025] The present invention replaces the conventional target water temperature calculated based on parameters such as engine speed, load, intake air temperature and vehicle speed according to the engine target exhaust temperature and target knock relief angle, and the exhaust temperature calculated by the exhaust temperature model and the knock model of the electronic control system. Compare the parameters of the temperature and detonation angle to judge the combustion state of the engine. If the engine exhaust temperature and detonation angle are higher than the target exhaust temperature and detonation angle, the electronic thermostat will be energized. The value size is controlled.

[0026] In addition, through the mechanical thermostat function of the electronic thermostat, combined with the engine running state, after logical judgment, the temperature adjustment function of the mechanical thermostat is given priority, so that the engine is in the best working temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com