Rubber ball collecting equipment

A technology of equipment and rubber balls, which is applied in the field of condenser cooling and pipe cleaning equipment, can solve the problems of obstructing the discharge of balls, long ball discharge paths, and large water resistance, and achieves the effect of not easy to block and high efficiency of ball collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

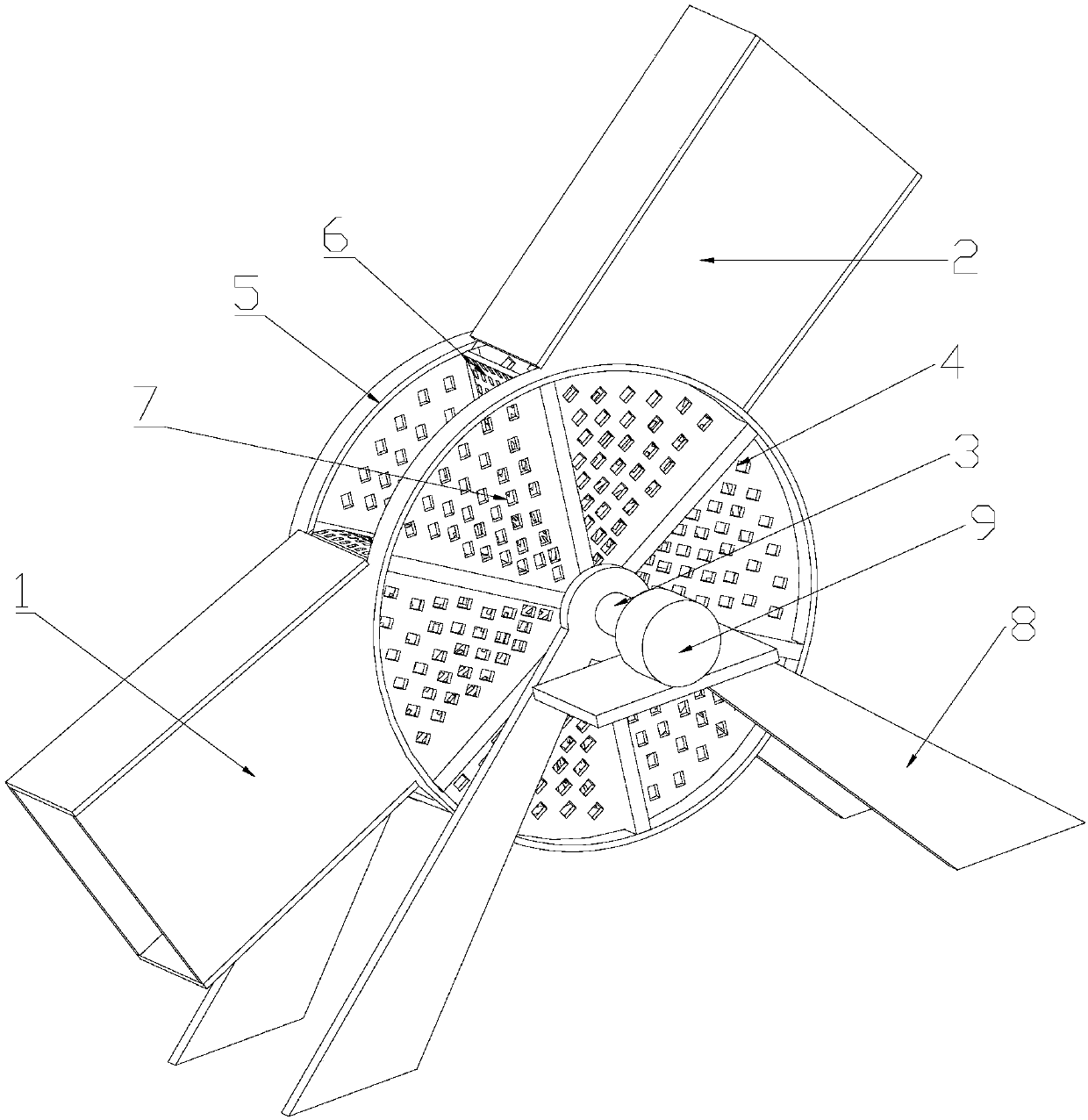

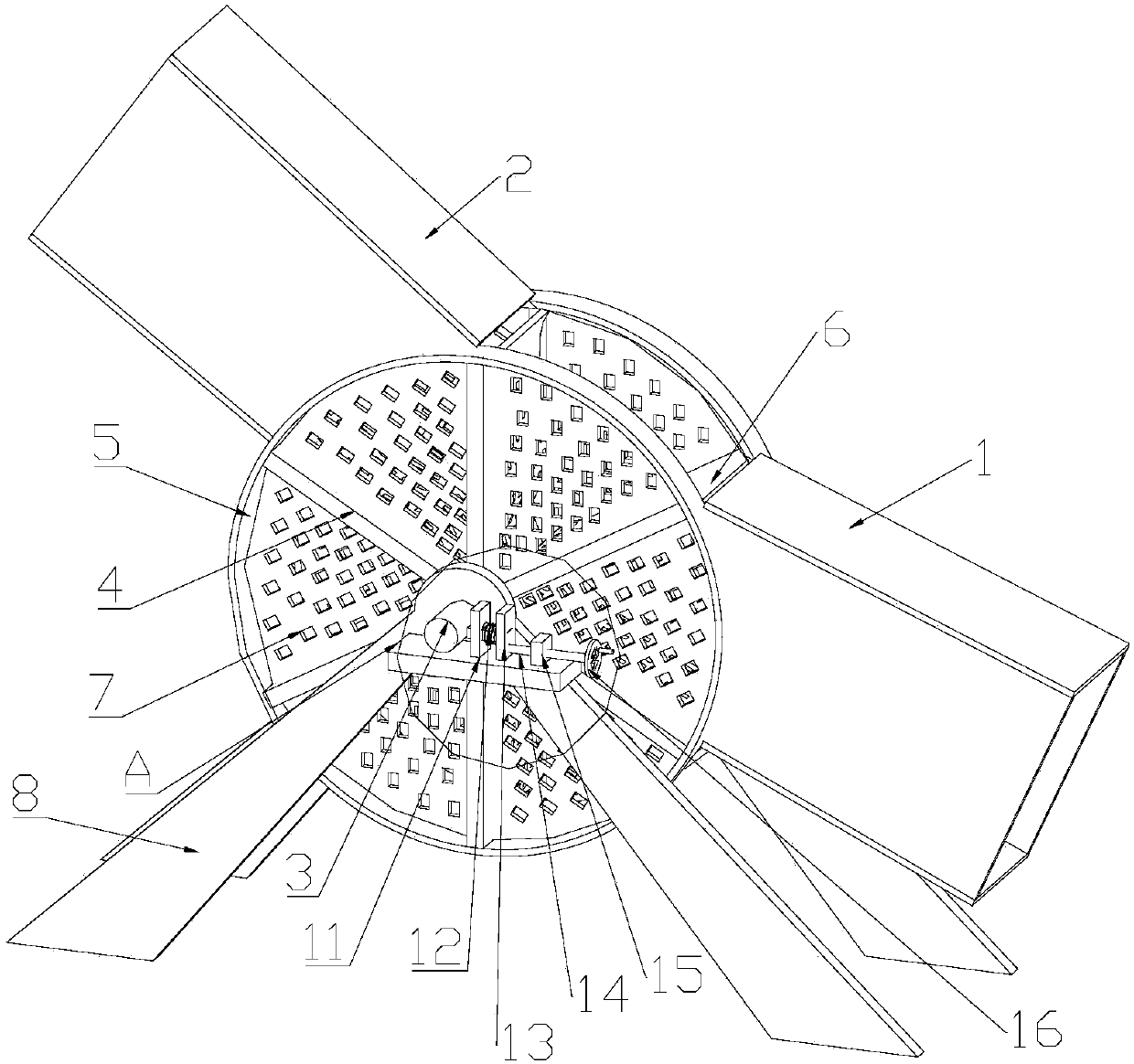

[0033] Example 1, the end of the rotating shaft 3 is connected to the motor 9, the rotating blade 6 is made of flexible hollow grid material, the motor 9 drives the rotating shaft 3 to rotate, the water flows down from the gap of the rotating blade 6, and then the rubber ball is trapped in the grid space, the grid space The outlet of the rubber ball is rotated to the nozzle of the slanted downward goal tube 1, and the rubber ball enters along the trend, thereby realizing the ball collection operation.

Embodiment 2

[0034] Embodiment 2, the rotating blade 6 is configured as a flexible mesh, and the connecting blade 7 is configured as a hollow mesh. The rotating blade 6 has no water leakage function, because the outlet of the ball tube 2 is set obliquely downward, so under the impact of the water flow and the rubber ball, the rotating blade 6 will rotate, thereby driving the rotating shaft 3 to rotate, and then driving the entire mechanism to rotate , and in the process of rotation, because the connecting blade 7 is hollowed out, the water flows downstream under the action of gravity, while the rubber ball is trapped, and when it rotates to the nozzle of the goal tube 1, it is thrown off the inlet and outlet tube , and then complete the ball collection operation.

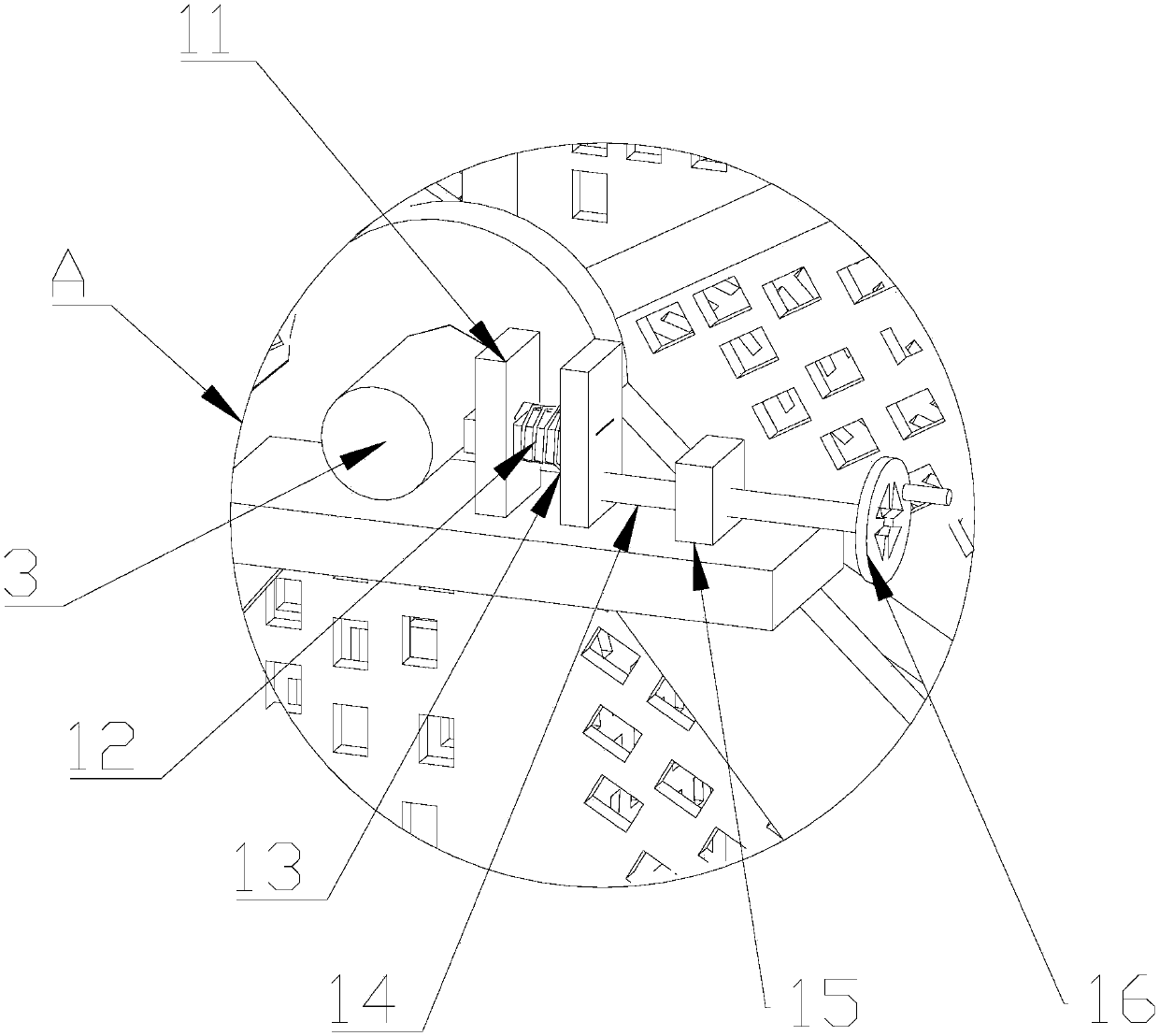

[0035] When the water potential flowing out from the outlet pipe 3 is constant, when the rotating speed of the rotating shaft 3 needs to be adjusted, the rotating speed can be slowed down so that the screw 14 can be moved toward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com