Tea stir-frying mechanism

A stir-frying mechanism and technology of tea leaves, which are applied in tea processing before extraction, etc., can solve problems such as low quality, difficulty in ensuring the quality of fresh tea roasting, and insufficient roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

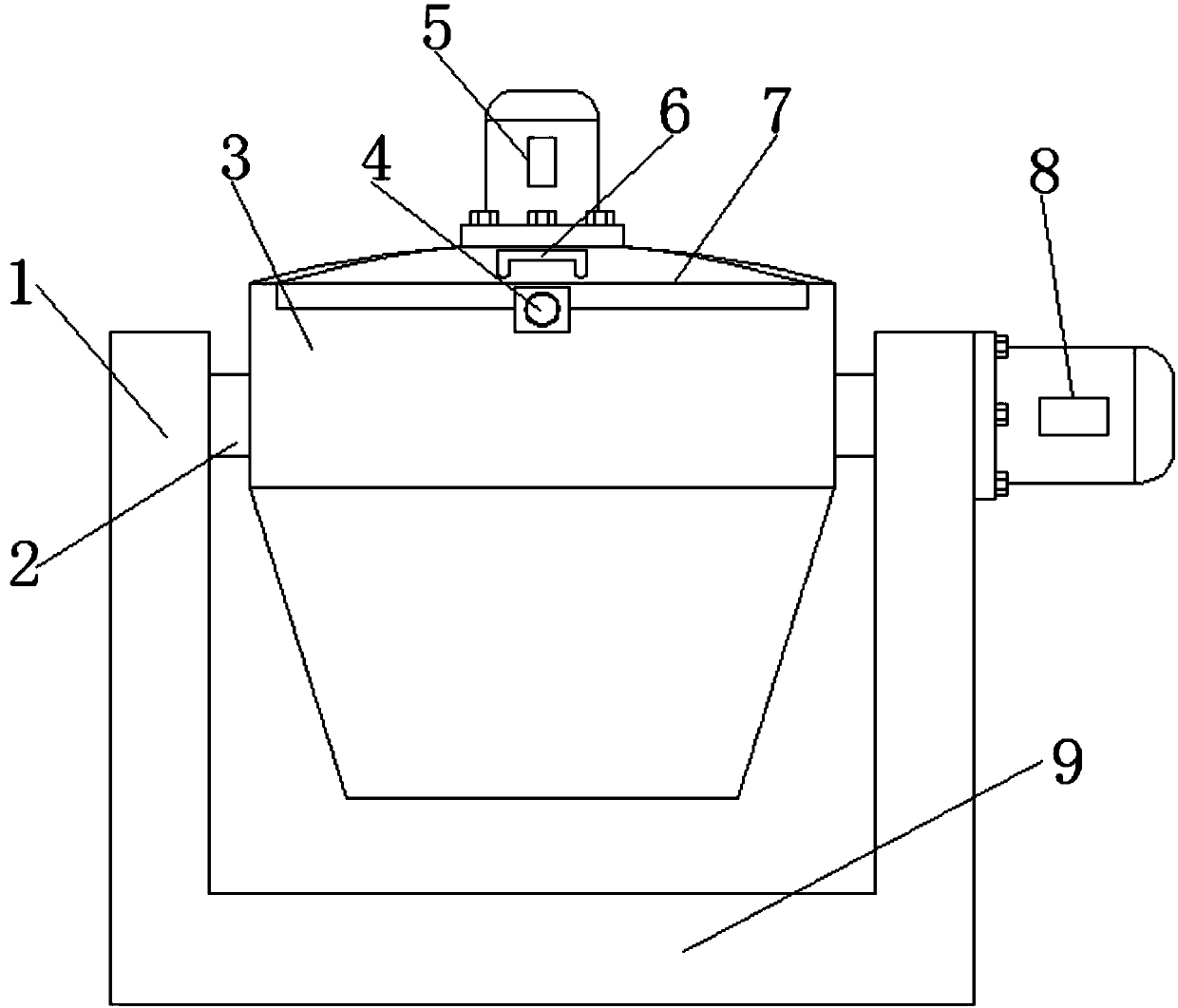

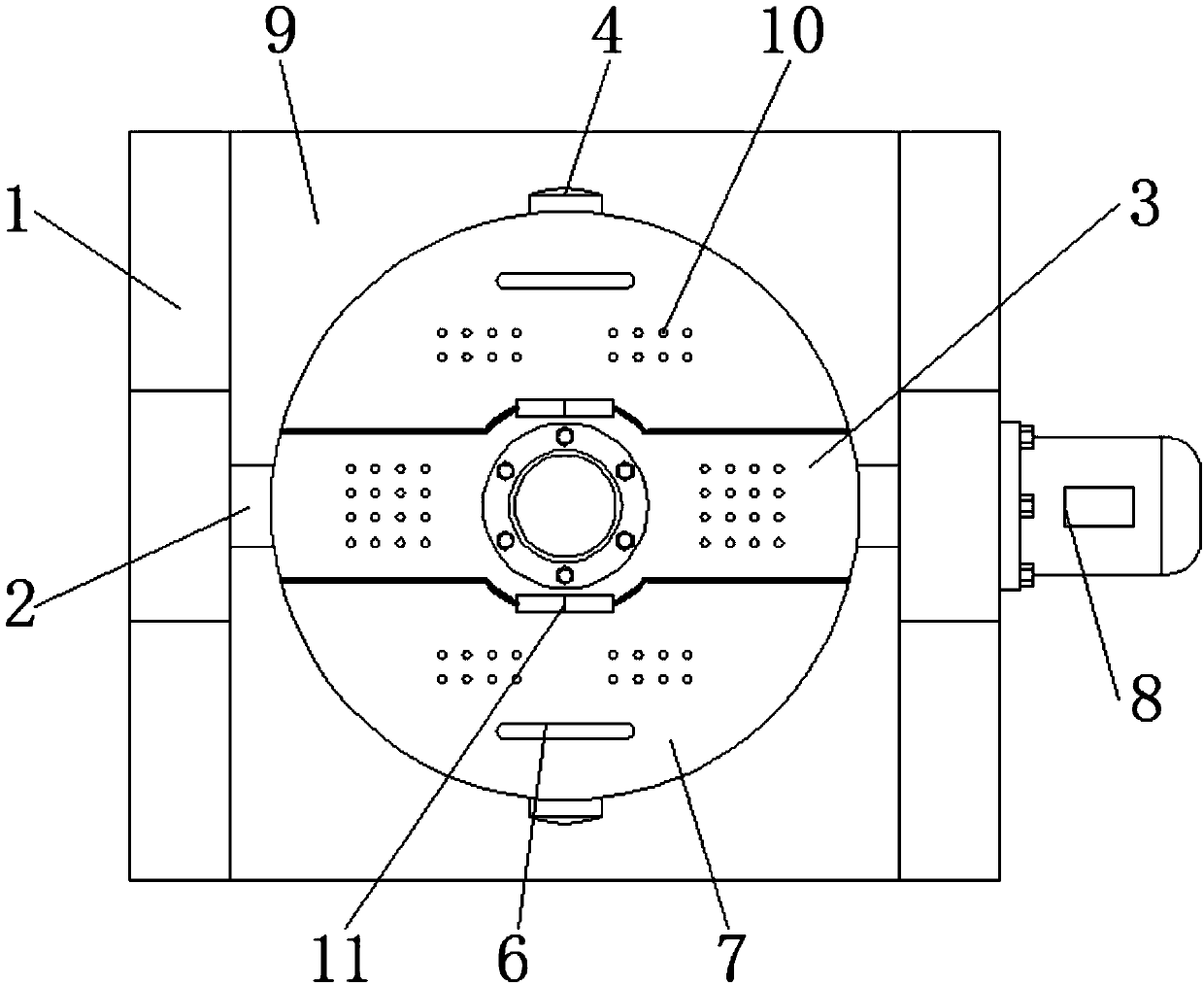

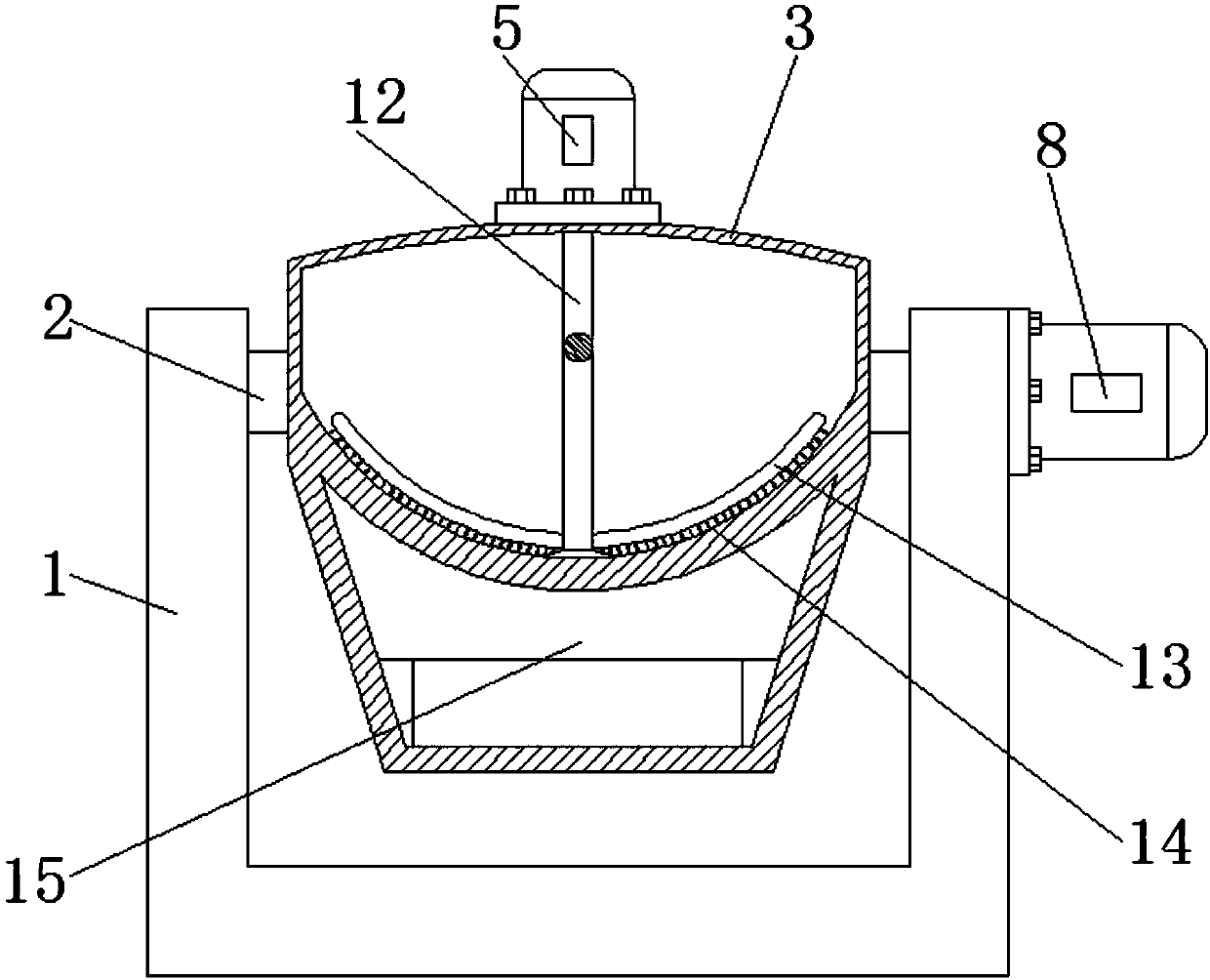

[0024] Such as Figure 1-Figure 4 As shown, a stir-frying mechanism for tea processing mainly includes a fixed connecting plate 1, a rotating shaft 2, a main body 3, a safety lock 4, a rotating motor 5, a handle 6, a movable cover 7, a swing motor 8, a supporting base 9, Air vent 10, connect fixed pin 11, stir-fry main shaft 12, the first stir-fry sub-shaft 13, stir-fry bristles 14, heating equipment 15 and the second stir-fry sub-shaft 16, the upper end of fixed connecting plate 1 passes through rotating shaft 2 and Main body 3, and a safety lock 4 is installed on the upper side of the main body 3, the main body 3 forms a rotating structure through the rotating shaft 2 and the fixed connecting plate 1, and the rotating motor 5 is located at the center of the upper end of the main body 3, which improves the tumbling of tea leaves inside the main body 3 Efficiency increases the stir-frying effect of tea leaves, and also ensures the performance of the rotary motor 5. The lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com