Numerical control rotary workbench with harmonic reducer

A technology of harmonic reducer and rotary table, which is applied in the direction of manufacturing tools, controlling mechanical energy, metal processing equipment, etc. The effect of outside space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

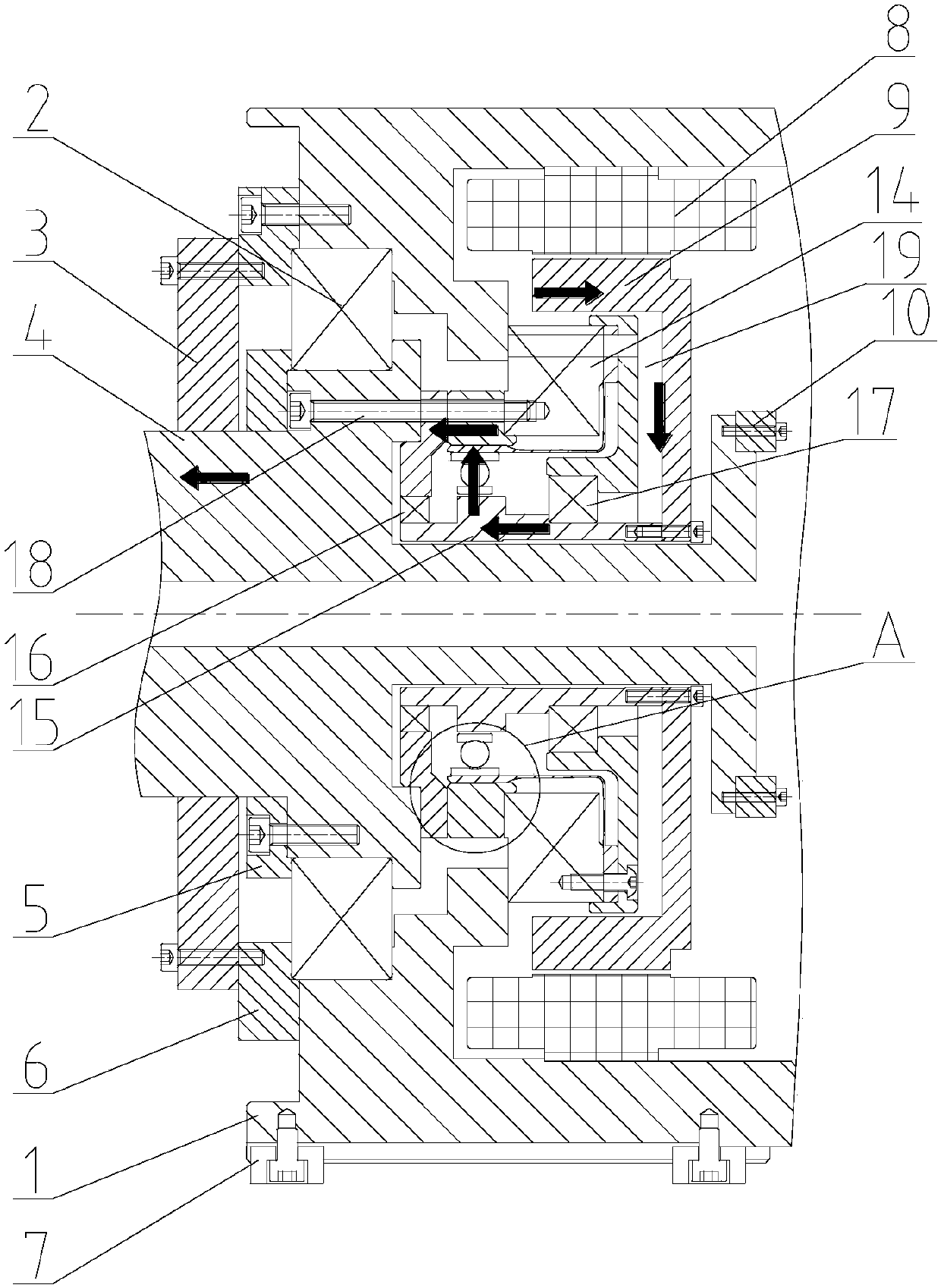

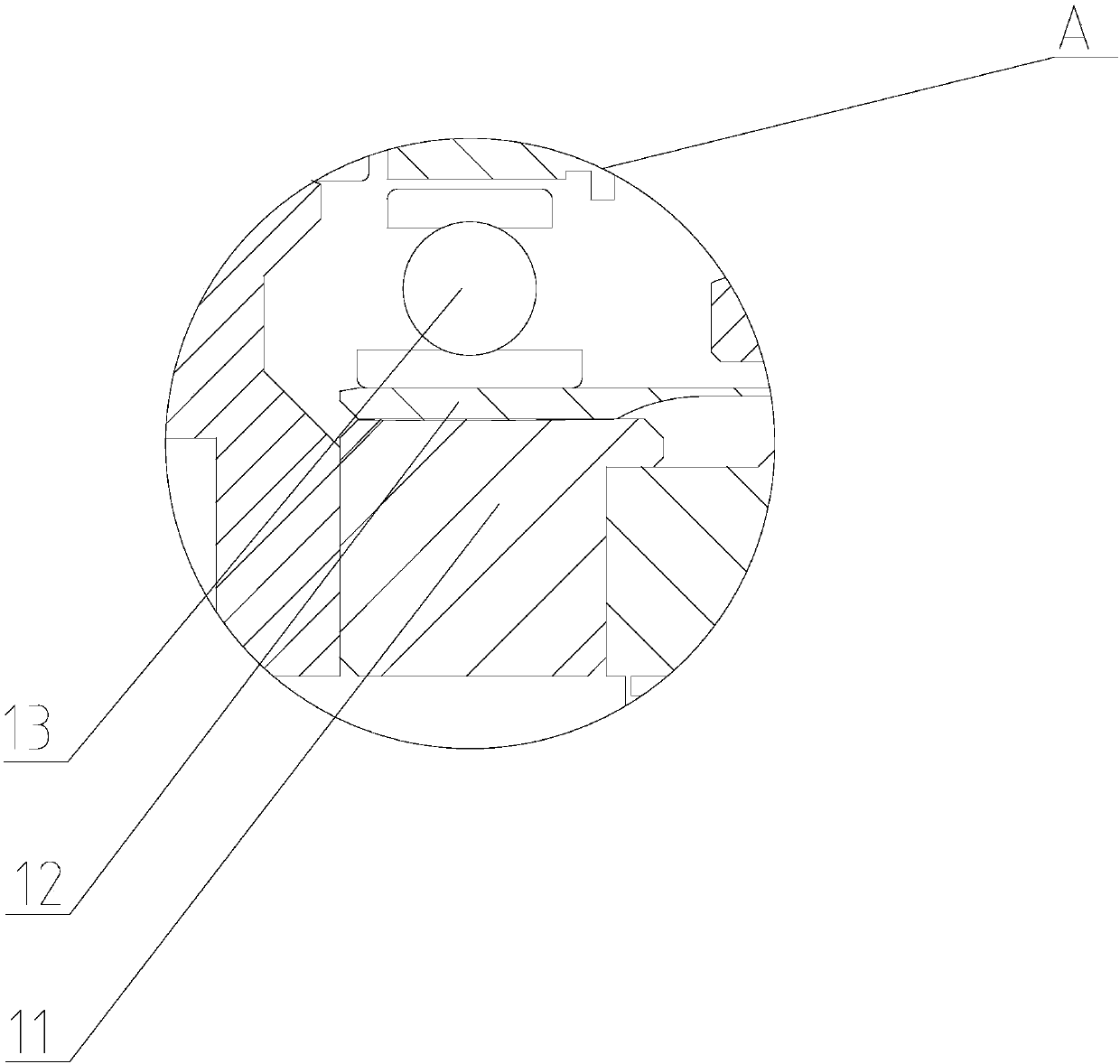

[0019] Such as figure 1 A CNC rotary table with a harmonic reducer is shown, including a motor housing 1, a stator 8, a rotor 9, an output shaft 4 for rotating and positioning materials, and a shaft for adjusting the output torque of the output shaft 4 Harmonic reducer, the stator 8 is fixedly installed in the motor housing 1, the rotor 9 is rotatably installed on the stator 8, and the area between the rotor 9 and the output shaft 4 forms an installation cavity for accommodating the harmonic reducer chamber 19, the harmonic reducer is fixedly installed on the installation chamber 19, and the harmonic reducer is connected with the rotor 9 and the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com