Fixator for metal impact specimen

A technology of impacting specimens and fixtures, applied in the direction of grinding workpiece supports, etc., can solve problems such as inability to absorb and have no magnetism, and achieve the effect of stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

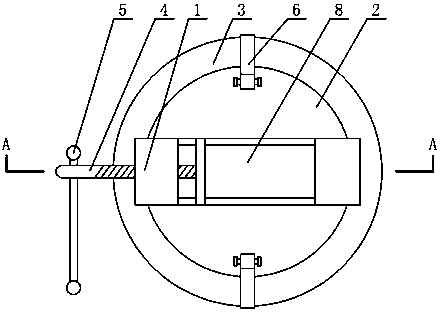

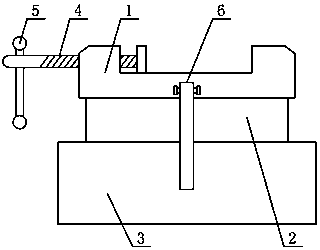

[0023] combined with Figure 1-4 As shown, a metal impact sample holder includes a holder 1 and a fastening screw 4. The holder 1 is a cuboid with protrusions at both ends, and the protrusion at one end is provided with a threaded hole. The threaded hole is compatible with the fastening screw 4, and a cylindrical fixing seat 2 is integrally formed under the holder 1, and a mounting platform 3 is arranged under the fixing seat 2, and the upper surface of the installing platform 3 is arranged There is a cavity for accommodating the fixing base 2, and the lower surface of the installation table 3 is provided with an installation hole 9 adapted to the installation rod of the machine tool.

[0024] The present invention is further elaborated below:

[0025] Align the mounting hole 9 on the lower part of the mounting table 3 with the mounting rod of the machine tool. After the mounting table 3 is installed, place the fixing seat 2 in the upper cavity of the mounting table 3, and pl...

Embodiment 2

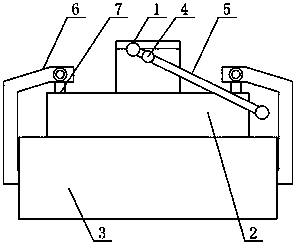

[0027] On the basis of Example 1, in conjunction with the attached Figure 1-3 As shown, further, the fixed base 2 is integrally formed with a lug 7 with a round hole, the lug 7 is hinged to the fastener 6 with a rectangular cross section through a round shaft, and the side wall of the mounting table 3 A rectangular hole compatible with the fastener 6 is provided.

[0028] The present invention is further elaborated below:

[0029] Align the mounting hole 9 at the bottom of the mounting table 3 with the mounting rod of the machine tool. After installing the mounting table 3, place the fixing seat 2 in the cavity above the mounting table 3, and rotate the fastener 6 hinged on the fixing seat 2. Insert the fastener 6 into the rectangular hole opened on the side wall of the installation platform 3, place the impact sample in the holder 1 on the upper part of the fixing seat 2, and rotate the tightening screw 4 to fix the impact sample. Clamped between the boss on one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com