Method for simultaneously extracting peanut oil and peanut protein

A peanut oil and protein technology, applied in the field of agricultural resources, can solve the problems of low utilization value, loss of nutrients, destruction of peanut protein and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

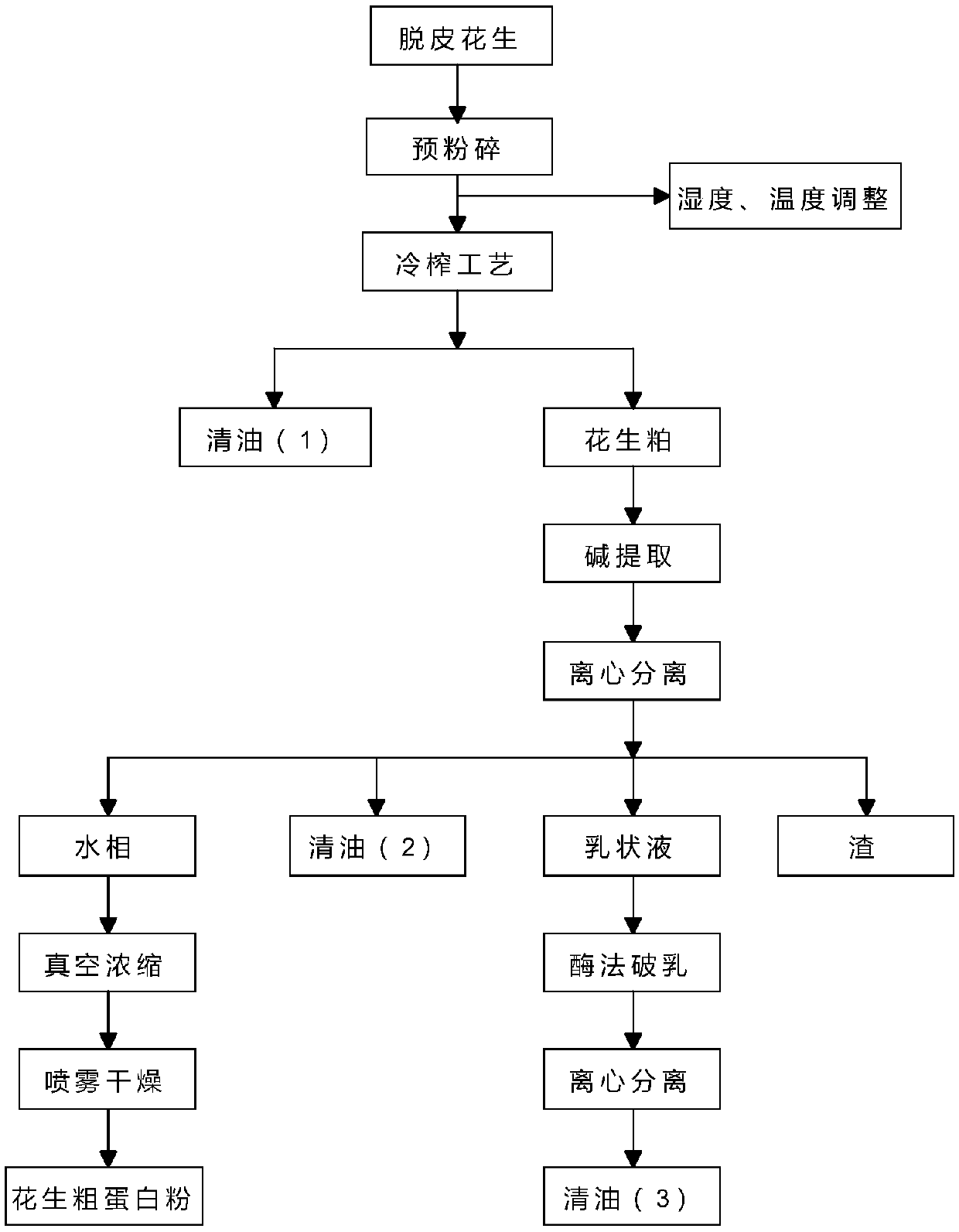

Method used

Image

Examples

Embodiment 1

[0024] (1) After pre-crushing the peeled peanuts (50.21% oil content, 21.26% protein content) into 4-8 petals, adjust the moisture content to 9%, and perform cold pressing at a pressing temperature of 40°C to obtain cold pressed peanuts. Peanut crude oil is obtained by filtering the crude oil with a plate and frame filter to obtain cold-pressed peanut oil (cold-pressed clear oil).

[0025] (2) Step (1) The peanut oil obtained after cold pressing accounts for 40% of the total oil content. 1 weight of peanut meal is crushed through a 60-mesh sieve and mixed with 6 parts by weight of water, and the pH value is adjusted at a temperature of 50 ° C and 2 mol / L NaOH to 8, extract for 4 hours, and the stirring speed is 200r / min. Carry out centrifugation under the condition of 4000g then, obtain peanut oil phase (clear oil), emulsion liquid phase, water phase and slag phase.

[0026] (3) Add 1 times the weight of water to the emulsion obtained in step (2), add 0.5% papain (W / W) (manuf...

Embodiment 2

[0033] (1) After pre-crushing the peeled peanuts (50.21% oil content, 21.26% protein content) into 4-8 petals, adjust the moisture content to 12%, and perform cold pressing at a pressing temperature of 60°C to obtain cold pressed peanuts. Peanut crude oil is obtained by filtering the crude oil with a plate and frame filter to obtain cold-pressed peanut oil (cold-pressed clear oil).

[0034] (2) The peanut oil obtained after cold pressing accounts for 45% of the total oil content. 1 weight of peanut meal is crushed through an 80-mesh sieve and mixed with 5 parts by weight of water, and the pH value is adjusted to 8.5 at a temperature of 60 ° C and 2 mol / L NaOH. Extract for 6h, the stirring speed is 200r / min. Then carry out centrifugation under the condition of 3000g to obtain peanut oil phase (clear oil), emulsion liquid phase, water phase and slag phase.

[0035] (3) Add 0.5 times the weight of water to the emulsion phase obtained in step (2), add 0.5% Protex 7L (W / W) (manufa...

Embodiment 3

[0039] (1) After pre-crushing the peeled peanuts (50.21% oil content, 21.26% protein content) into 4-8 petals, adjust the moisture content to 15%, and perform cold pressing at a pressing temperature of 45°C to obtain cold pressed peanuts. Peanut crude oil is obtained by filtering the crude oil with a plate and frame filter to obtain cold-pressed peanut oil (cold-pressed clear oil).

[0040](2) The peanut oil obtained after cold pressing accounts for 50% of the total oil content. 1 weight of peanut meal is crushed through a 100-mesh sieve and mixed with 7 parts by weight of water, and the pH value is adjusted to 9.5 at a temperature of 60 ° C and 4 mol / L NaOH. Extract for 3 hours, the stirring speed is 200r / min. Then carry out centrifugation under the condition of 3500g to obtain peanut oil phase (clear oil), emulsion liquid phase, water phase and slag phase.

[0041] (3) Add 1.5 times the weight of water to the emulsion phase obtained in step (2), add 0.5% Alcalase 2.4L (W / W)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com