Boehmeria nivea peeling machine

A technology of ramie and hemp skin, applied in the field of ramie peeling machine, can solve the problems of low efficiency of ramie peeling, and achieve the effect of strong skin and bone separation ability, convenient movement and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

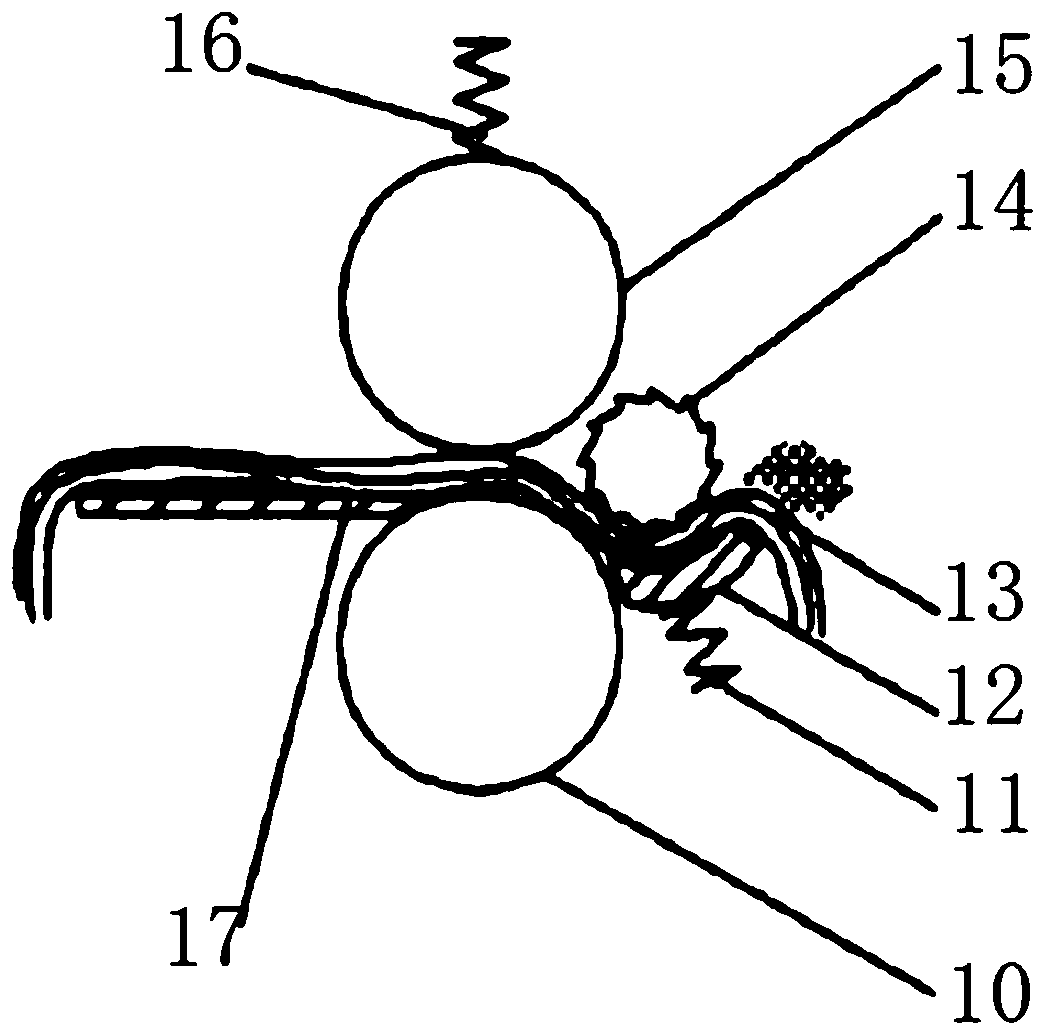

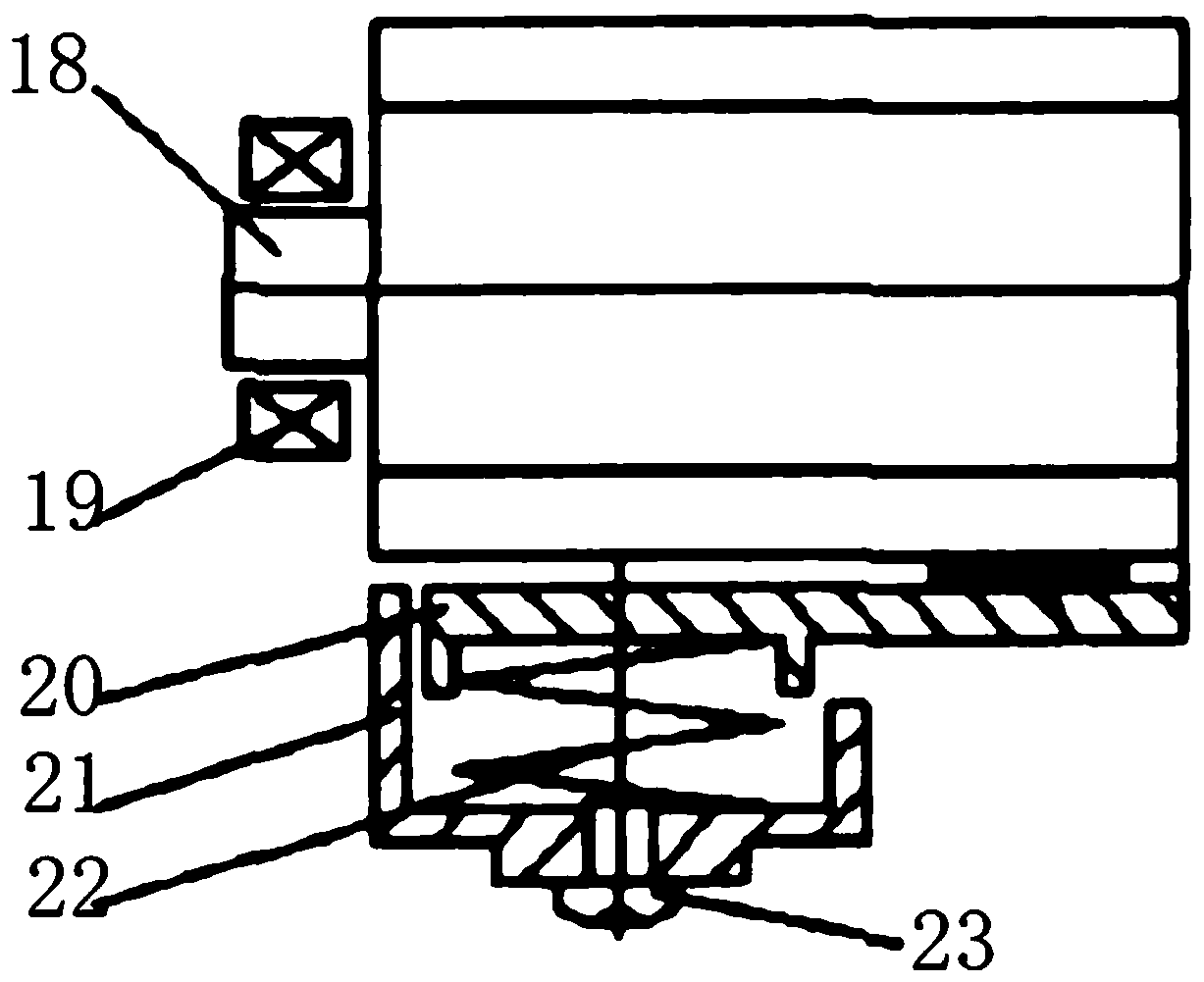

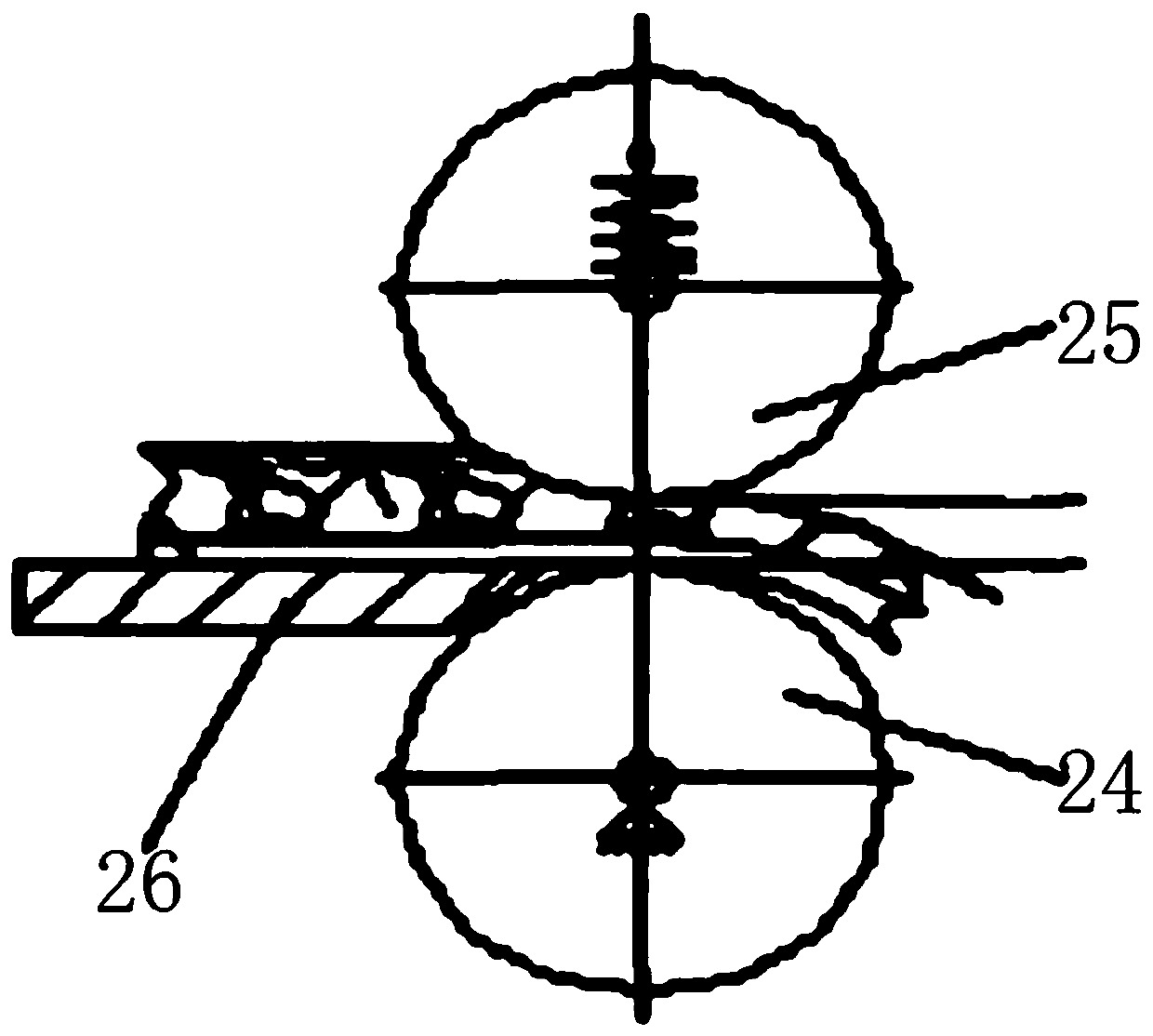

[0018] It includes rubber conveying wheels, scrapers, hobs, rubber pressure wheels, pressure wheels, compression springs, compression screws, sliding bearings, and feeding tables. It is characterized in that: the rubber transmission wheels are driven by the motor through the gearbox ) rotates clockwise, the rubber pressure wheel (4) clings to the rubber conveying wheel under the action of the compression spring (6), and rotates counterclockwise at the same linear speed under the action of friction, and the root of the hemp bark passes through the feeding The stage (9) is fed between the rubber conveying wheel and the rubber pressure wheel, and the colloid and water are squeezed out under the pressure of the compression spring and the rubber pressure wheel. When the hemp skin enters the hob (3) and the scraper (2) After the gap, the hob blade teeth cut and squeeze the tensioned hemp husk at a certain relative speed under the relative action of the scraper to remove the hemp husk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com