Thick-wall pipeline bevel fit-up method

A pipe bevel and pipe technology, which is applied in the direction of manufacturing tools, welding equipment, welding accessories, etc., can solve the problems of unfavorable gap size, affecting welding quality, and damaging the base material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below by specific examples.

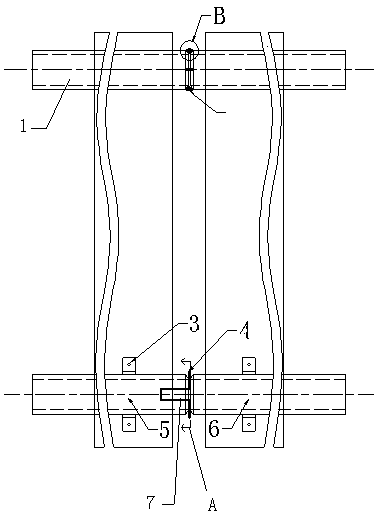

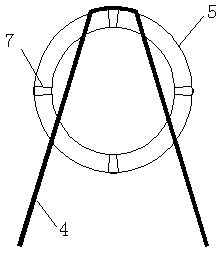

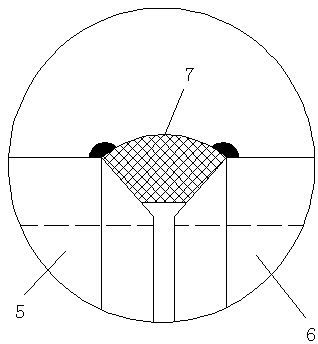

[0020] like Figure 1~Figure 3 As shown, a pairing method of thick-walled pipe grooves includes a working platform 1, a pipe positioning frame 3, a gap adjustment ruler 4, and a gap positioning block 7. The pairing method includes

[0021] Step 1. Place the two sections of pipelines 5 and 6 that need to be connected on the working platform 1;

[0022] Step 2. Use the pipe positioning frame 3 to respectively fix the two sections of pipes on both sides of the working platform;

[0023] Step 3, insert the gap adjustment ruler 4 into the gap between the two sections of pipelines 5 and 6, and the gap adjustment ruler 5 is attached to the port of any section of the pipeline;

[0024] Step 4. Adjust the two sections of pipelines 5 and 6 so that the gap adjustment ruler 4 fits the two sections of pipelines at the same time;

[0025] Step 5, insert a gap positioning block 7 at the gap between the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com