Movable platform system of pressing machine

A mobile platform and mobile worktable technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of inability to realize automatic mobile mold change, no positioning, etc., and achieve the effect of automatic regulation, smooth movement and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

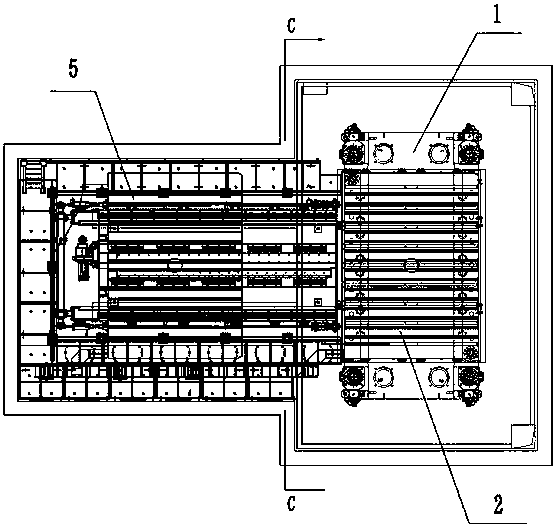

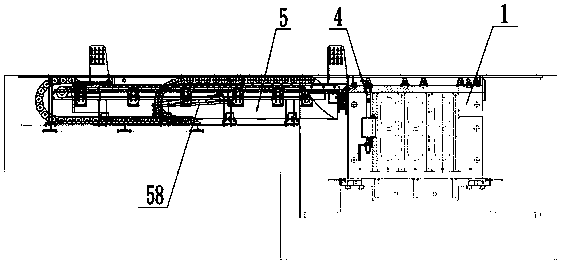

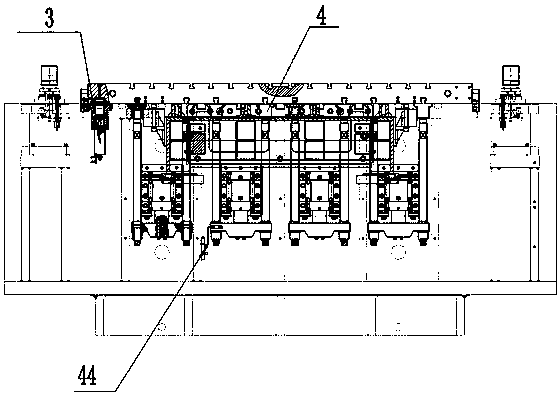

[0042] see Figure 1 to Figure 3 , a press mobile platform system, including a press base 1, a mobile workbench 2, a positioning mechanism 3, a locking mechanism 4 and a mobile base 5;

[0043] see Figure 4 to Figure 7 , the mobile worktable 2 is movably arranged above the press base 1, and the upper surface of the mobile worktable 2 is provided with a strip-shaped upper card slot 21 passing through the front end and the rear end of the mobile workbench 2 along its moving direction , the upper card slot 21 is used to install the mould; in this embodiment, the number of the upper card slot 21 is multiple, and several upper card slots 21 are arranged at intervals and parallel to each other. The lower surface of the mobile workbench 2 is provided with a strip-shaped lower card slot 22 that runs through the front end and the rear end of the mobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com