A leaf threshing and redrying processing method for simultaneously regulating the structure of tobacco slices and the stalk content rate in leaves

A technology of threshing and redrying and processing methods, which is applied in the fields of tobacco, tobacco treatment, application, etc., and can solve the problems of insufficient and effective screening, secondary crushing, and unresolved problems of screening too large leaves, etc., to achieve The cost and process difficulty are limited, the occupied space is small, and the effect of good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

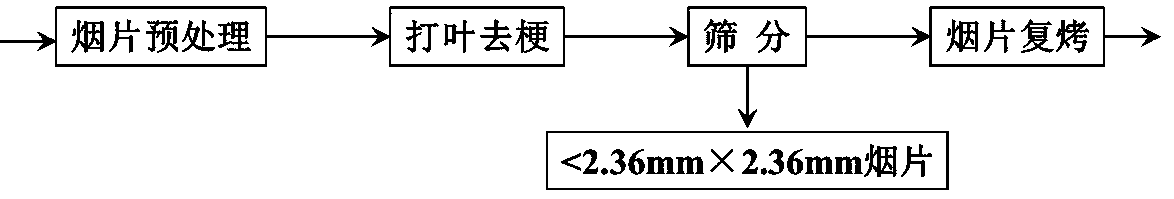

Problems solved by technology

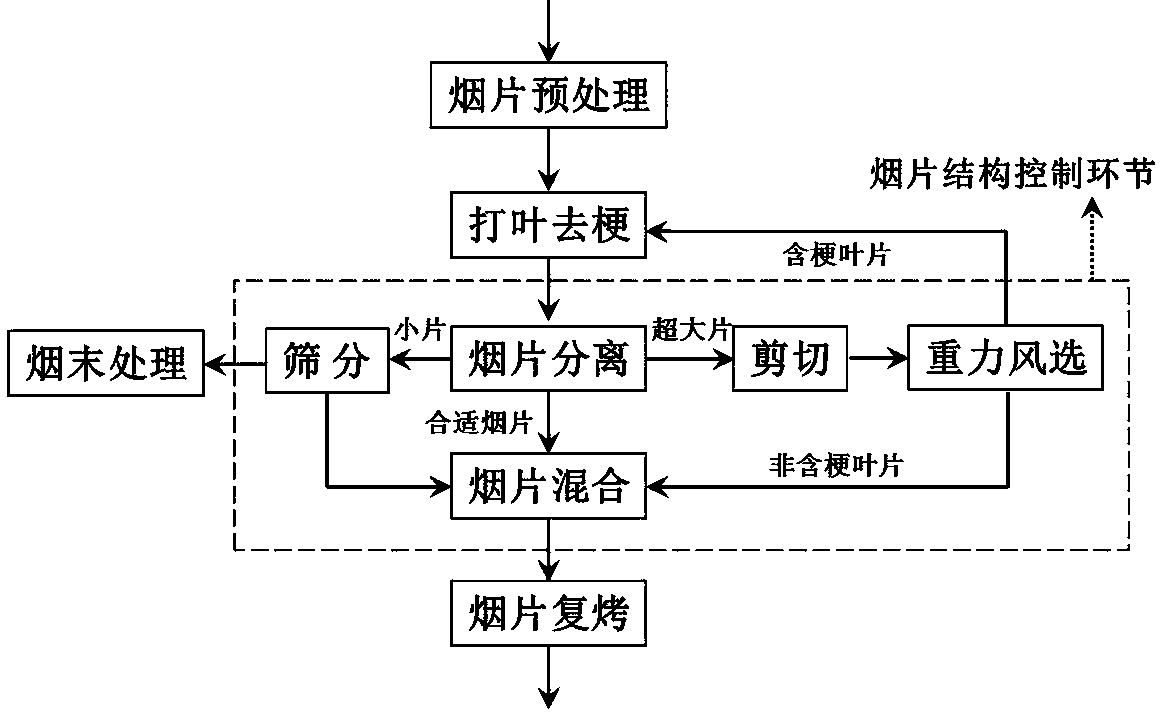

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Using C3F grade tobacco leaves in the Pingdingshan area of Henan as the test material, the existing threshing and redrying mode and the threshing and redrying processing mode described in this patent were used to test respectively, and the tobacco structure and processing economy of the two processing modes were compared. sex;

Embodiment 2

[0037] Embodiment 2 takes B2F tobacco leaves in Nanping area of Fujian as the test material, and takes the currently clear thin cigarette tobacco sheet structure as the goal, adopts the threshing and redrying processing mode described in this patent to carry out the test, and adjusts the parameters of the equipment to make the tobacco sheet. The structure meets the structural requirements of thin cigarettes.

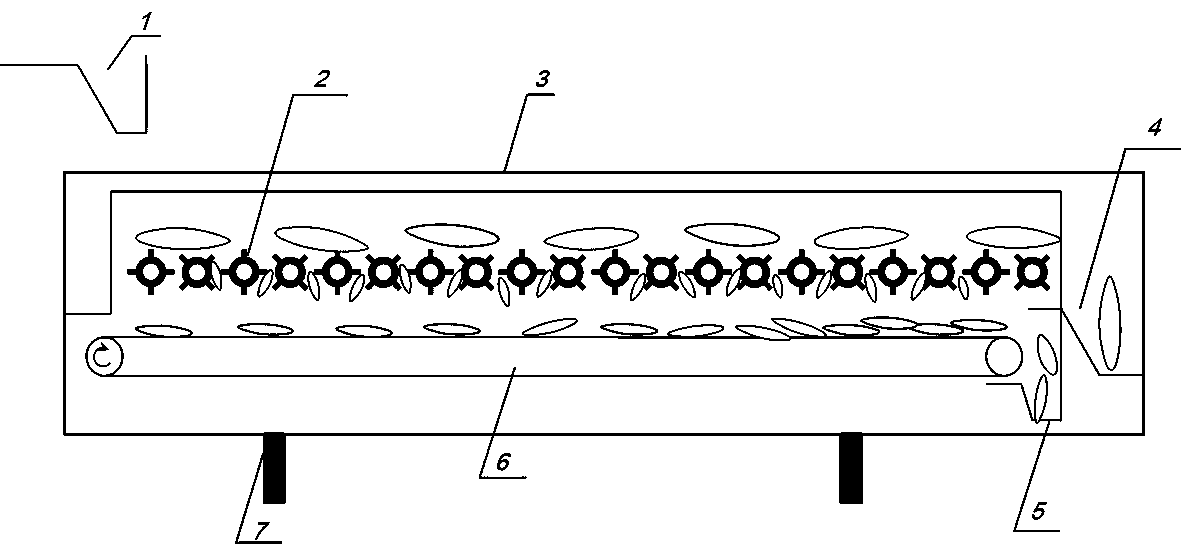

[0038] The screening device adopted in the following examples is designed by the inventor, and its structure is as follows: image 3 , 4 As shown, it is a multi-roller toggle type tobacco leaf screening device,

[0039]The device includes a main body support 7, a frame groove body 3 set on the main body support, and a material conveying device 6 at the bottom of the frame groove body 3. The front end of the frame groove body 3 is provided with an incoming material blanking port 1. The upper part of the end is provided with a large-size tobacco sheet discharge port 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com