Method for controllable modulating of distribution of Fischer-Tropsch reaction product through Co-based catalyst

A Fischer-Tropsch reaction and catalyst technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of improving the difficulty of product separation and purification and catalyst recovery process, and achieve sensitive and high-speed product switching. Effects of reactivity, high olefin selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 0.74g Co(NO 3 ) 2 ·6H 2 O, 0.04mL mass fraction is 50% Mn(NO 3 ) 3 4H 2 O aqueous solution, 0.05gZr(NO 3 ) 4 ·5H 2 O, 0.015g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 20mL of water and stirred evenly to make a mixed solution. Weigh 0.85gSiO2 2 Carrier, mix the mixture with the carrier evenly, impregnate in vacuum at room temperature for 5 hours, separate solid and liquid, wash with water, and dry at 100°C for 12 hours to obtain a solid powder; mix the obtained solid powder with 0.5g of phenylalanine, and the mixed powder is heated at 500°C Calcined for 5 hours, ground, pressed into tablets, and sieved to obtain 15%Co-1%Mn-1%Zr-0.5%Ce-0.05%N-0.1%C / SiO 2 catalyst.

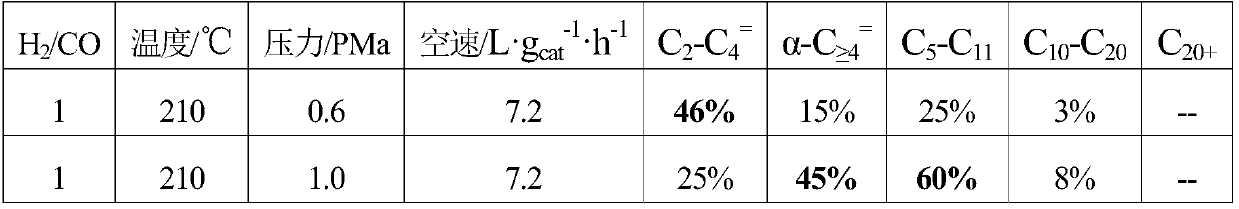

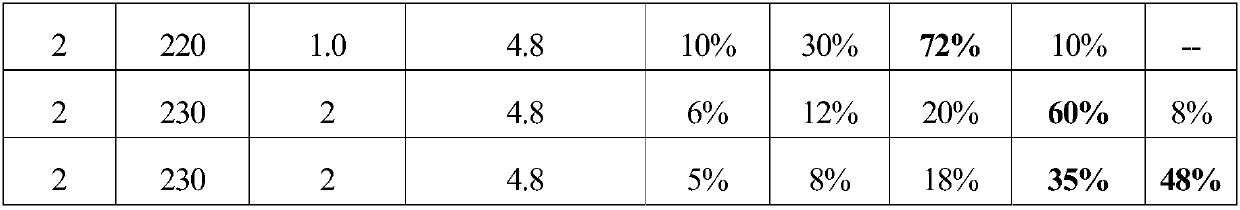

[0020] 0.5g 15%Co-1%Mn-1%Zr-0.5%Ce-0.05%N-0.1%C / SiO 2 The catalyst is mixed with an equal volume of quartz sand, placed in a fixed-bed reactor, and pure H 2 Gas (H 2 =99.9%), heated up to 450°C at a rate of 5°C / min, maintained for 5h, then cooled to 180°C, fed into synthesis gas, and carried out the...

Embodiment 2

[0024] 0.50g Co 2 (CO) 8 , 0.09g Mn(Ac) 2 , 0.047g Zr(NO 3 ) 3 ·6H 2 O, 0.03g Ce(NO 3 )3 ·6H 2 O was dissolved in 20mL of ethanol and stirred evenly to make a mixed solution. Weigh 1.0g SiO2 2 Carrier, mix the mixed solution with the carrier evenly, impregnate in vacuum at room temperature for 5 hours, separate solid and liquid, wash with water, and dry at 100°C for 12 hours to obtain a solid powder; mix the obtained solid powder with 1.0g of phenylalanine, and the mixed powder is heated at 500°C Roast for 5h, grind, press into tablets, and sieve to get 20%Co-2%Mn-1%Zr-1%Ce-0.1%N-0.1%C / SiO 2 catalyst.

[0025] 0.5g 20%Co-2%Mn-1%Zr-1%Ce-0.1%N-0.1%C / SiO 2 The catalyst is mixed with an equal volume of quartz sand, placed in a fixed-bed reactor, and pure H 2 Gas (H 2 =99.9%), heated up to 450°C at a rate of 5°C / min, maintained for 5h, then cooled to 180°C, fed into synthesis gas, and carried out the Fischer-Tropsch reaction of synthesis gas to hydrocarbon products acco...

Embodiment 3

[0029] 0.50g Co(NO 3 ) 2 ·6H 2 O, 0.02mL 50% Mn(NO 3 ) 3 4H 2 O, 0.10g Zr(NO 3 ) 4 ·5H 2 O, 0.031g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 20mL of water and stirred evenly to make a mixed solution. Weigh 1.0g Al 2 o 3 Carrier, mix the mixed liquid with the carrier evenly, impregnate in vacuum at room temperature for 5 hours, separate solid and liquid, wash with water, and dry at 100°C for 5 hours to obtain a solid powder; mix the obtained solid powder with 0.5g melamine, and roast the mixed powder at 500°C for 5 hours, Grinding, tableting, and sieving to obtain 10%Co-0.5%Mn-2%Zr-1%Ce-0.08%N-0.05%C / Al 2 o 3 catalyst.

[0030] 0.5g 10%Co-0.5%Mn-2%Zr-1%Ce-0.08%N-0.05%C / Al 2 o 3 The catalyst is mixed with an equal volume of quartz sand, placed in a fixed-bed reactor, and pure H 2 Gas (H 2 =99.9%), heated up to 450°C at a rate of 5°C / min, maintained for 5h, then cooled to 180°C, fed into synthesis gas, and carried out the Fischer-Tropsch reaction of synthesis gas to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com