A processing mold for seamless underwear and its application method

A seamless underwear and mold processing technology, which is applied in the field of clothing, can solve the problems of excessive price of seamless underwear, high use and maintenance costs, etc., and achieve the effects of easy operation, reduced production costs, and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

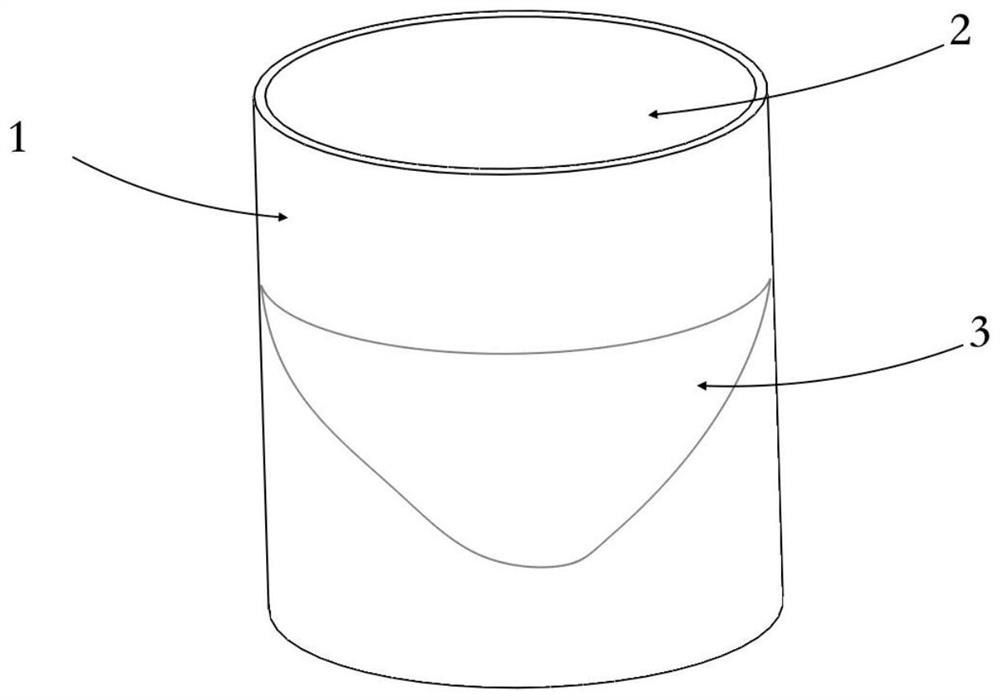

[0025] A processing mold for seamless underwear, such as figure 1 shown. The mold 1 as a whole is made of elastic materials, such as rubber or silicone elastic materials. The mold 1 has a flat cylinder hollow structure 2 inside, and the outer surface of the mold 1 is provided with a dent 3 having the same shape as the underwear. The depth of the dent 3 ranges from 0.1 to 1 mm, which is equivalent to the thickness of the underwear.

[0026] Both the top and the bottom of the mold 1 are open, and an expansion part (not shown in the figure) is installed inside the hollow structure 2 of the mold 1 . Preferably, the expansion part is an inflatable airbag. With the expansion of the inflatable air bag, the mold is also expanded at any time, so that it can be suitable for producing seamless underwear of the same style but different sizes.

[0027] The types of underwear that can be processed and produced by the processing mold of the present invention include underwear, vests or on...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that the mold is a sealed hollow structure capable of inflating and deflating, and the mold is equipped with an air nozzle. In this way, the mold itself is an inflatable airbag without an additional inflatable airbag, which further simplifies the structure of the mold. For ease of placement, the bottom of the mold is flat.

Embodiment 3

[0031] The present embodiment provides the using method of the processing mold in the above-mentioned embodiment 1, comprises the following steps:

[0032] Step 1. Select matching molds according to the type and size range of underwear to be produced;

[0033] Step 2. Inflate the inflatable air bag to make the mold reach the precise and suitable size;

[0034] Step 3. Brush or spray the liquid material of underwear fabric in the dent on the outer surface of the mold;

[0035] Step 4, waiting for the liquid raw materials to solidify into underwear fabrics;

[0036] Step 5, taking off the underwear fabric from the mould, and obtaining the underwear garment after necessary trimming.

[0037] Further, after the liquid raw materials are solidified into underwear fabrics, the inflatable air bag is deflated to shrink the mold, and then the underwear fabrics are free from the dents by themselves.

[0038] Further, in step 3, a layer of isolation layer is first painted on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com