No-ballast-water speed increasing ship

A technology for ballasting water and hulls, applied to pipelines, hulls, and ship parts for emptying/ballasting, which can solve problems such as costing manpower and material resources, marine pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

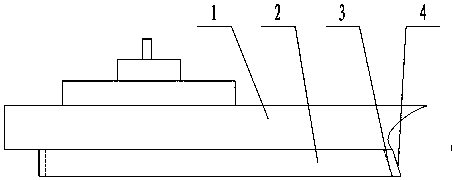

[0011] In the embodiment shown in the drawings, the present invention consists of a hull 1, a water pipe 2, a sealed door 3, and a fence 4. The water pipe 2 is divided into a plurality, and is installed on both sides of the hull 1 bottom storehouse. Both ends of the water pipe 2 are equipped with airtight doors 3, which can be opened and closed as required, either partially or all at the same time, and fences 4 are installed at both ends of each water pipe 2 to block foreign objects such as fish Enter.

[0012] The above description is the implementation of the preferred functions of the present invention, and is not intended to limit the present invention. Any modifications made within the spirit and principles of the present invention are equivalent to replacements and improvements, and should be included in the protection scope of the present invention. Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com