A verification method for crane heave compensation function

A wave compensation and function verification technology, applied in cranes, load hoisting components, transportation and packaging, etc., can solve problems such as suspension, sinking of ships, and threats to the safety of supply operations at sea, so as to improve the test efficiency and simplify the test method. , the effect of shortening the trial period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

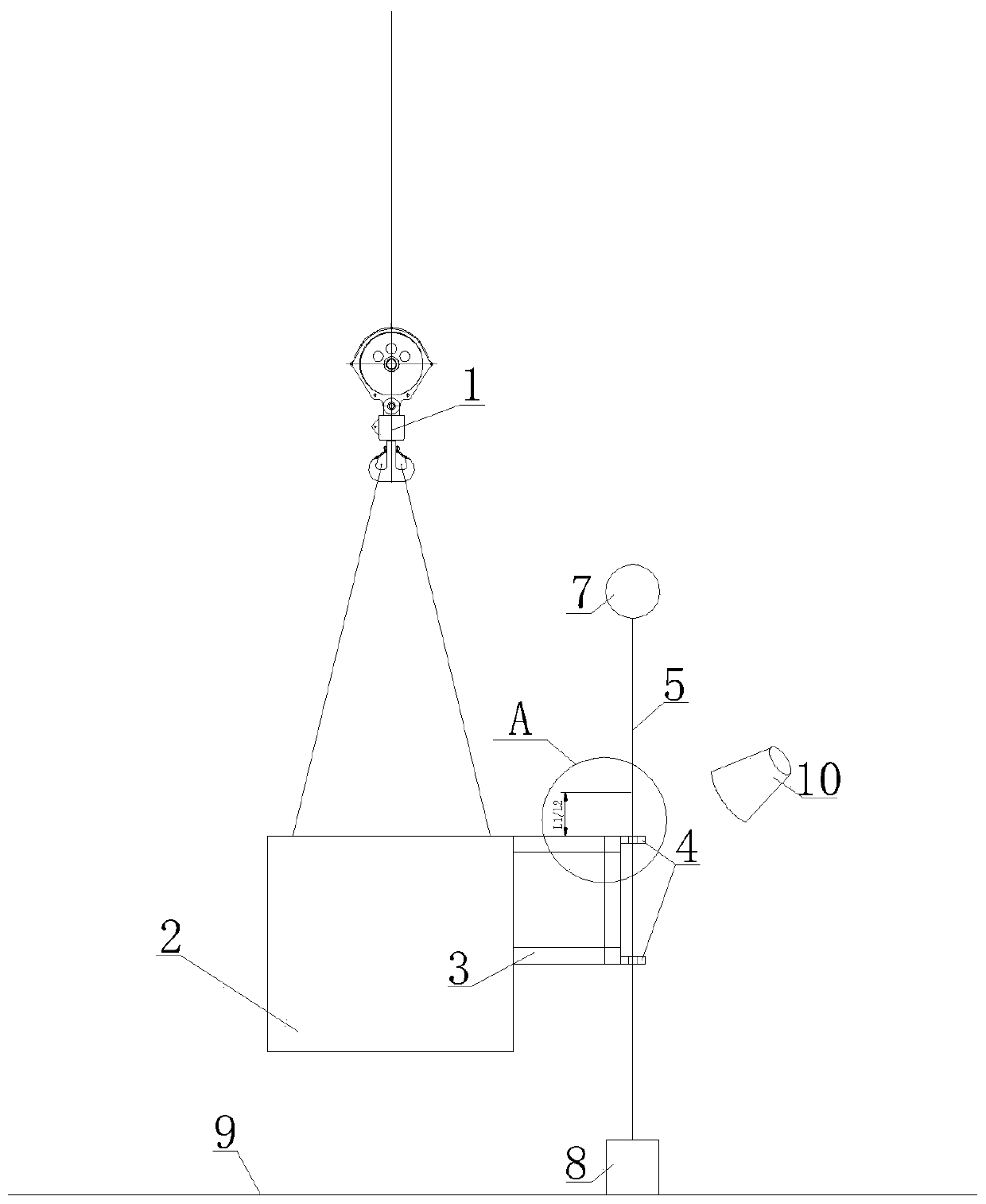

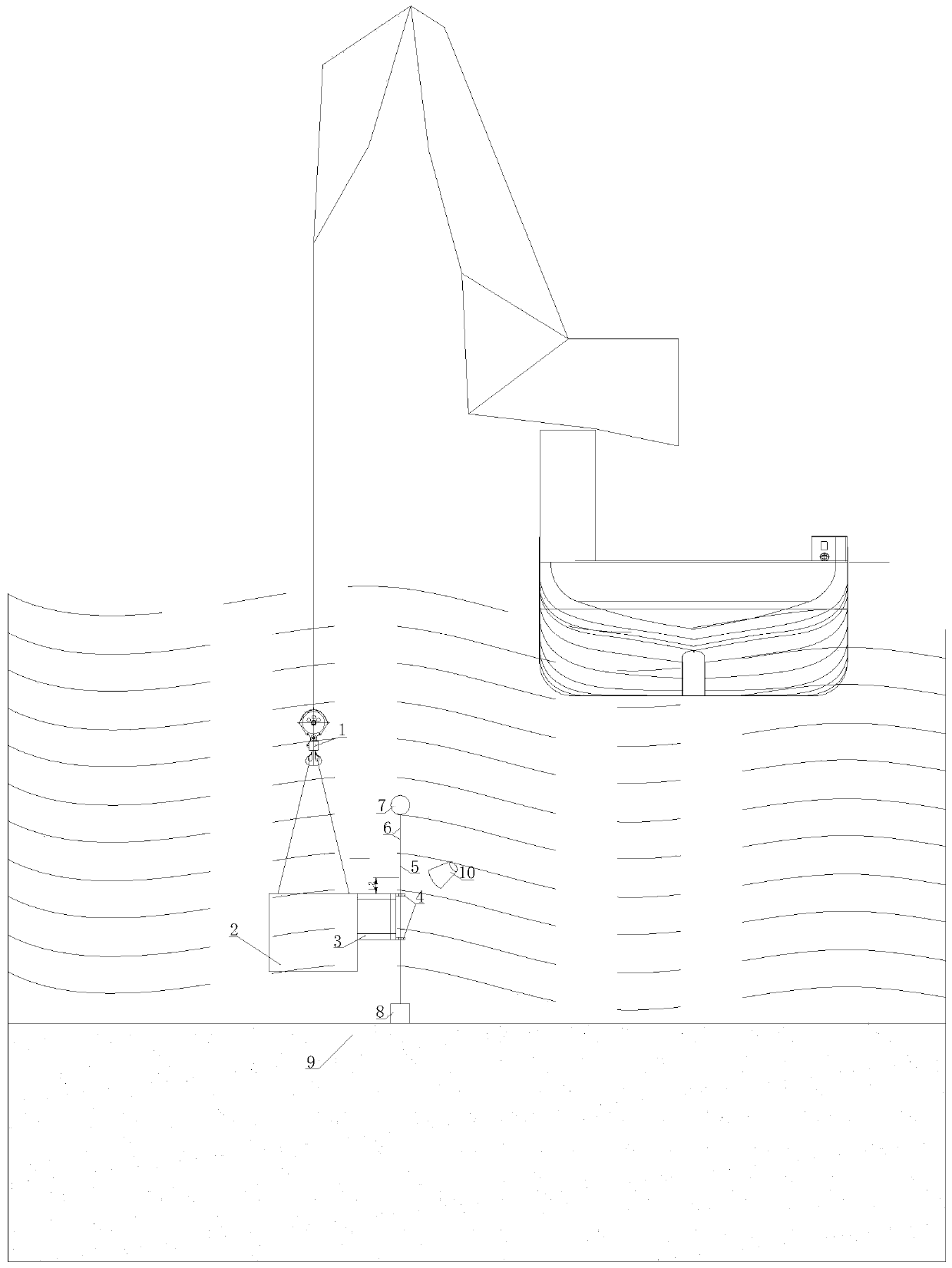

[0019] Such as Figure 1-3 As shown, this embodiment provides a crane heave compensation function verification method, including the following steps:

[0020] 1) The function verification of the crane heave compensation system is carried out on the basis of the load test. During the test, the hook of the crane 1 hangs the load bracket 2;

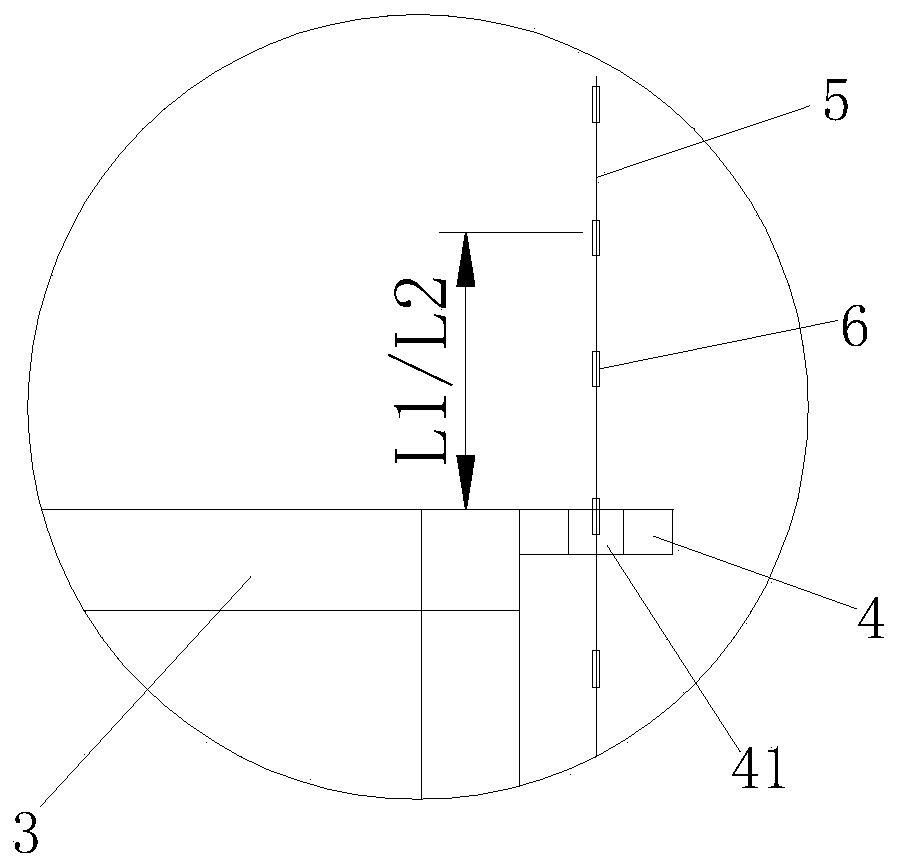

[0021] 2) A "mouth"-shaped tooling frame 3 is installed on one side of the load-bearing bracket 2, and steel plates 4 are respectively installed on the upper and lower ends of the tooling frame 3, and concentric circular holes 41 are arranged on the two steel plates 4;

[0022] 3) Make a measuring rope 5, on which luminescent marks 6 are arranged at continuous intervals. During the test, a floating ball 7 is installed on the upper end of the measuring rope 5, and a counterweight 8 is installed on the lower end. The gravity of the counterweight 8 is greater than that of the floating ball 7. buoyancy;

[0023] 4) Before the crane 1 test, pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com