Method for replacing tower foot of transmission tower

A replacement method, a technology for iron towers, applied to towers, building types, buildings, etc., can solve the problems of large construction area, high work intensity, temporary power outages, etc., to reduce the construction area and reduce the workload , Guarantee the effect of normal electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

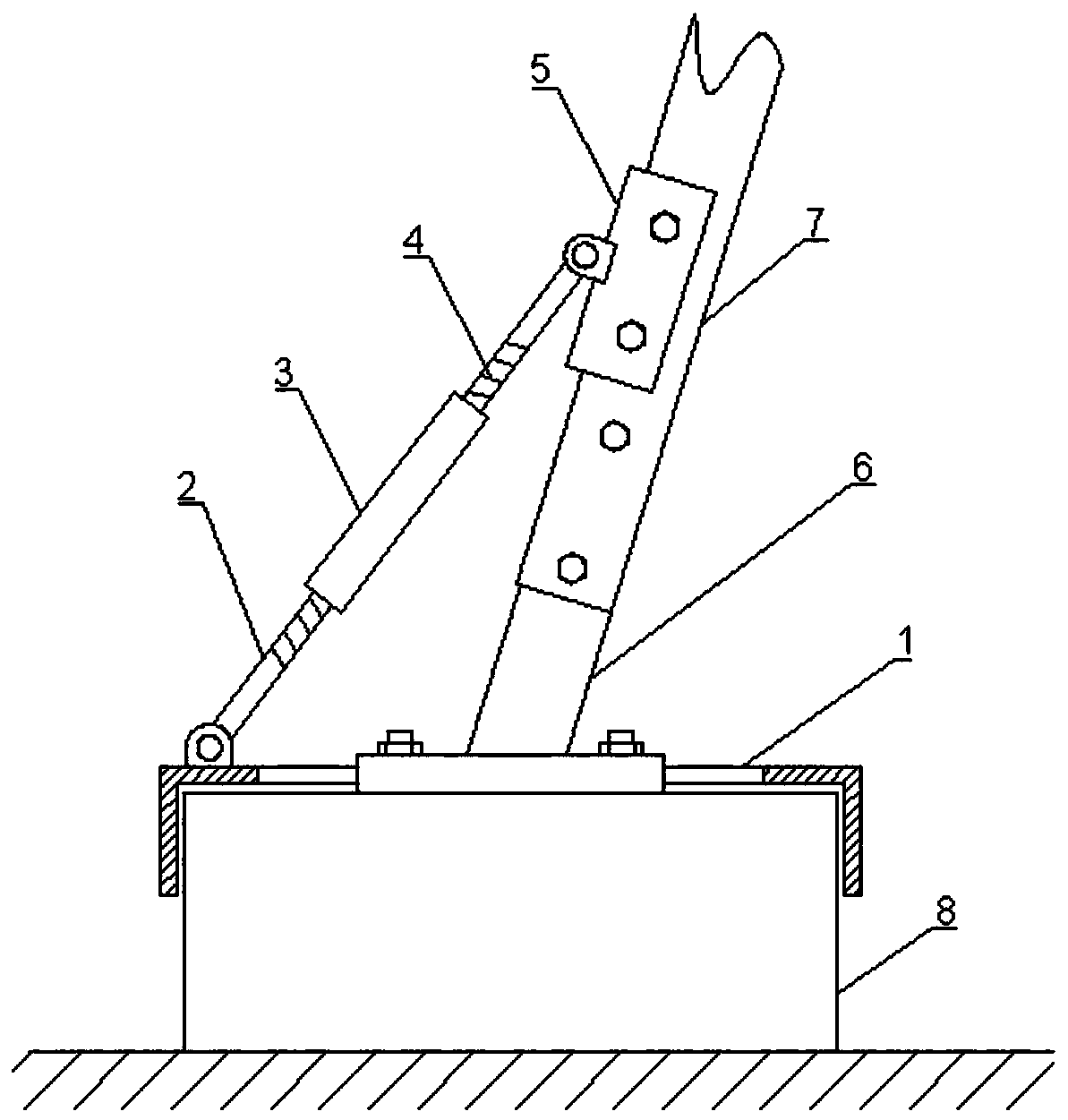

[0025] Such as figure 1 , figure 2 As shown, a transmission tower foot and main iron replacement method, the specific steps are as follows:

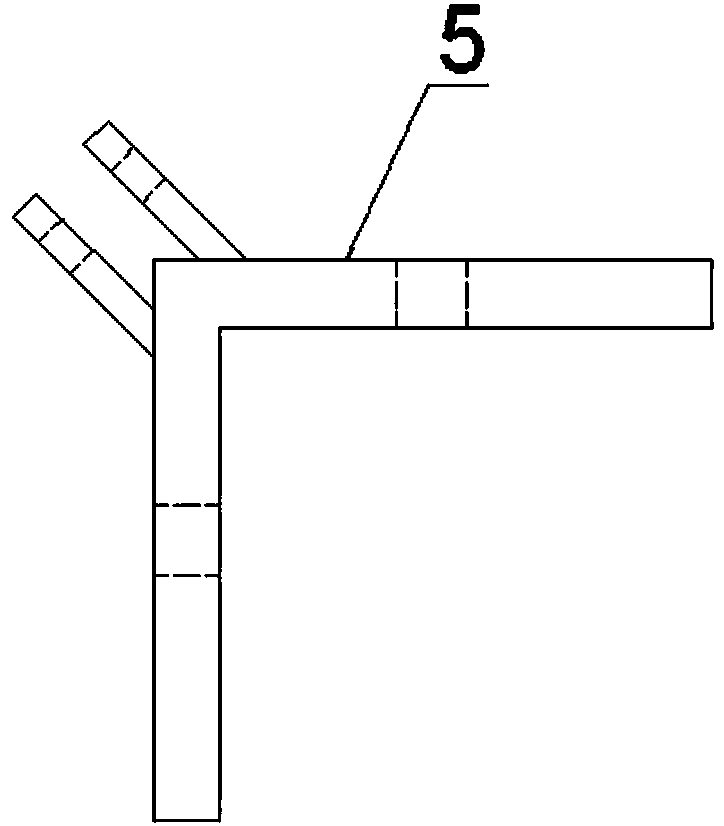

[0026] 1. Connect the support device between the tower foot where the tower foot 6 is to be replaced and the main iron 7. The support device includes a square frame-shaped support hoop seat 1, and the first screw rod is hinged on the top surface of the support hoop seat 1 through a pin shaft 2. Install the threaded sleeve 3 on the top of the first screw rod 2, and install the second screw rod 4 on the inner top of the threaded sleeve 3. The upper and lower thread directions of the threaded sleeve 3 are opposite, and the corresponding first screw rod 2 and the second screw rod The thread direction of the second screw mandrel 4 is opposite, and the support connector 5 is articulated at the top of the second screw mandrel 4 by a pin shaft. The support hoop seat 1 is installed on the tower base 8 where the tower foot 6 is to be replaced, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com