Method for transforming coal-bed gas well into coal-measure gas well

A technology for coalbed methane wells and coal measure gas, which is applied in wellbore/well components, chemical instruments and methods, and earth-moving drilling, etc., and can solve the problems of poor compatibility between fracturing fluid and formation, small fracturing fluid consumption, and high construction pressure. , to achieve the effect of increasing reservoir permeability, increasing daily gas production, and increasing stimulation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

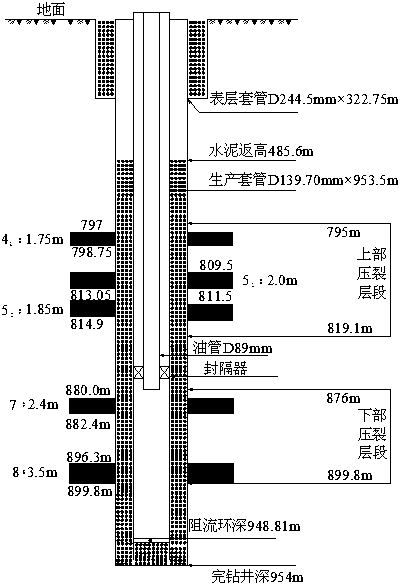

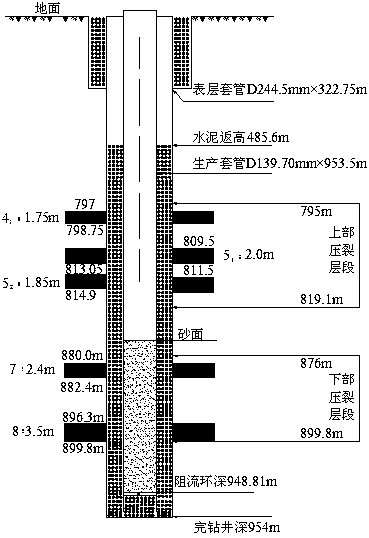

[0026] A method for transforming a coal-bed gas well into a coal-measure gas well, comprising the steps of:

[0027]1) Select a coalbed methane well CM-01 that has undergone coal seam transformation in the early stage but has poor transformation effect as the surface coalbed methane well for this transformation. A total of 1.19×10 5 m 3 According to the gas content of each layer of the well, the volumetric method is used to calculate the gas content of each well within the control range of a single well (0.1 km 2 ) the coal-measure gas resources in the transformed layer are 21.85×10 6 m 3 , the produced gas volume is less than 1% of the coal-measure gas resources in the reformed layer, and according to the current domestic economic and technical conditions, when the resource abundance reaches 1×10 8 m 3 / km 2 At the above time, it has commercial value, so the well can be used as a reformed well.

[0028] 2) Low-damage fracturing fluid was used for the reconstruction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com