A kind of chemical stimulation fluid for low permeability reservoir and preparation method thereof

A chemical stimulation and reservoir technology, applied in the field of oil drilling, can solve the problems of reservoir permeability damage, inability to completely solve the problems of filtrate intrusion into the reservoir, reduction of gas-bearing oil saturation, etc., so as to relieve the blockage of organic and/or inorganic scales , obvious production capacity release and production increase effect, the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

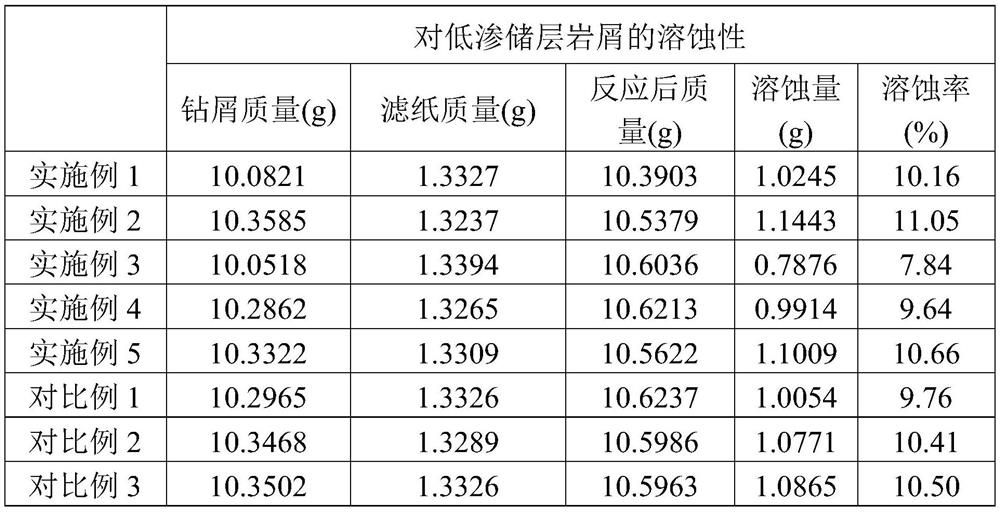

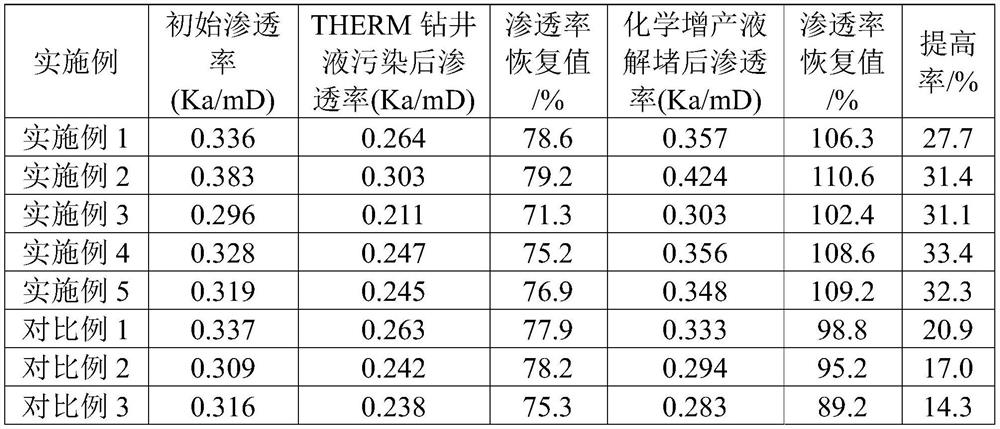

Examples

Embodiment 1

[0036] The chemical stimulation fluid for low-permeability reservoir provided in this example is based on the total weight of the chemical stimulation fluid being 100 parts by weight, and the chemical stimulation fluid includes the following components by weight:

[0037]20.0 parts by weight of the anti-pressure and drainage aid are mixed in the ratio of ethylene glycol: ethylene glycol propyl ether: propylene glycol=0.5:1.5:0.5.

[0038] 8.0 parts by weight of pore dredging agent, mixed in the ratio of acetic acid: sulfamic acid: ethylenediaminetetraacetic acid=2:2:5.

[0039] 2.5 parts by weight of waterproof locking agent, mixed by the ratio of cationic fluorocarbon surfactant: water-soluble organic silicon: nonionic fluorocarbon surfactant=0.5:3:0.5.

[0040] 2.0 parts by weight of clay stabilizer, mixed by vinyl cationic copolymer: organic amine polyoxyethylene ether: polydiallyl dimethyl ammonium chloride = 1:2:1.

[0041] The rest is fresh water.

[0042] The preparat...

Embodiment 2

[0045] The chemical stimulation fluid for low-permeability reservoir provided in this example is based on the total weight of the chemical stimulation fluid being 100 parts by weight, and the chemical stimulation fluid includes the following components by weight:

[0046] 15.0 parts by weight of the anti-pressure and drainage aid are mixed in the ratio of ethylene glycol: ethylene glycol propyl ether: propylene glycol=1.0:1.5:1.0.

[0047] 10.0 parts by weight of the channel dredging agent is mixed in the ratio of acetic acid: sulfamic acid: ethylenediaminetetraacetic acid=3:2:3.

[0048] 3.0 parts by weight of waterproof locking agent, mixed by cationic fluorocarbon surfactant: water-soluble organic silicon: nonionic fluorocarbon surfactant=1:2:1.

[0049] 2.0 parts by weight of a clay stabilizer, mixed in a ratio of vinyl cationic copolymer: organic amine polyoxyethylene ether: polydiallyl dimethyl ammonium chloride = 2:5:1.5.

[0050] The rest is sea water.

[0051] The p...

Embodiment 3

[0054] The chemical stimulation fluid for low-permeability reservoir provided in this example is based on the total weight of the chemical stimulation fluid being 100 parts by weight, and the chemical stimulation fluid includes the following components by weight:

[0055] 20.0 parts by weight of the depressurizing and drainage aid are mixed in a ratio of ethylene glycol: ethylene glycol propyl ether: propylene glycol = 1:1:1.

[0056] 5.0 parts by weight of pore dredging agent, mixed in the ratio of acetic acid: sulfamic acid: ethylenediaminetetraacetic acid=3:2:4.

[0057] 4.0 parts by weight of waterproof locking agent, mixed by cationic fluorocarbon surfactant: water-soluble organic silicon: nonionic fluorocarbon surfactant=1:3:1.

[0058] 2.0 parts by weight of a clay stabilizer, mixed in a ratio of vinyl cationic copolymer: organic amine polyoxyethylene ether: polydiallyl dimethyl ammonium chloride = 1.5:3:1.

[0059] The rest is a mixture of seawater and freshwater at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com