Bamboo sheet edge defect detection device

A defect detection and bamboo chip technology, applied in measuring devices, instruments, etc., can solve the problems of small spot range, false alarms, and inability to use in production lines, and achieve the effect of stable working performance and small interference factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

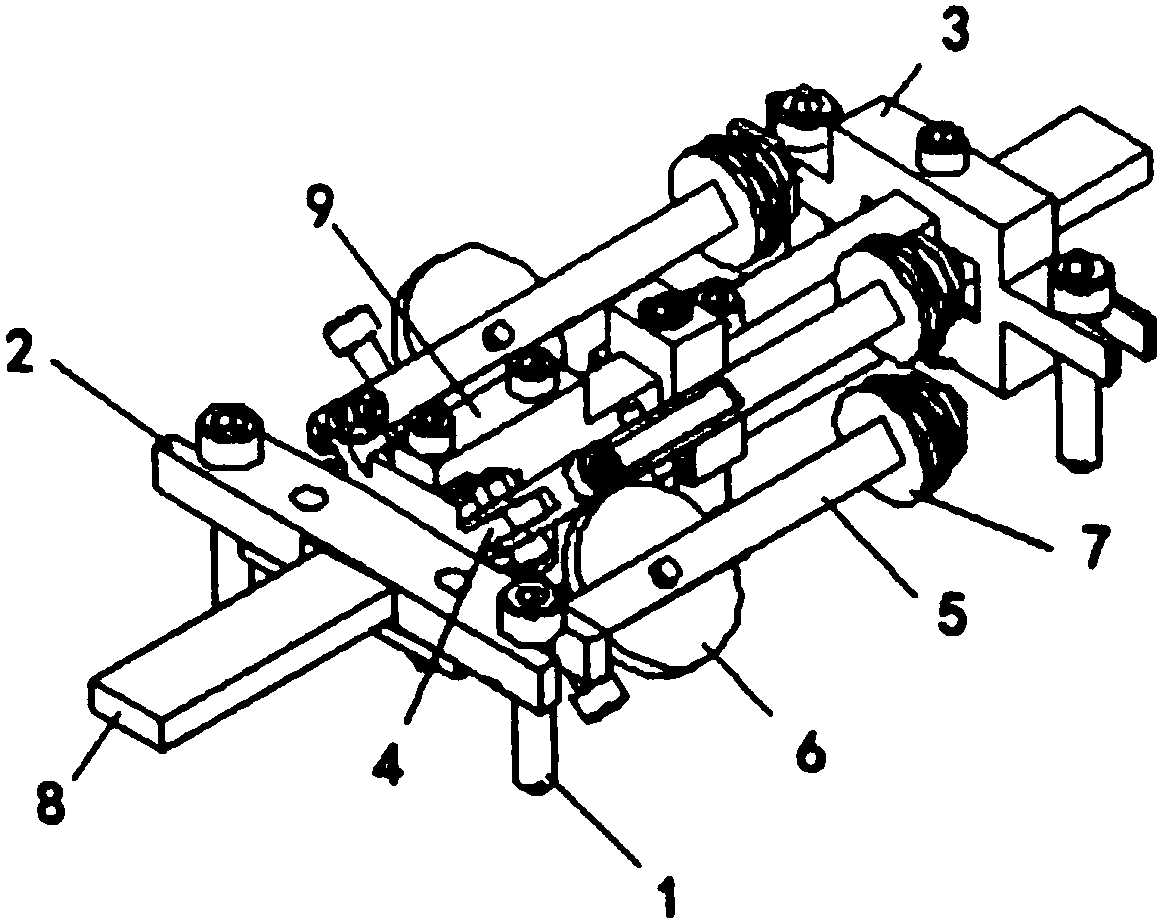

[0018] Examples such as figure 1 As shown, the bamboo edge defect detection device includes a leg 1, a front baffle 2, a rear baffle 3, a bracket ear 4, a detection lever 5, a detection roller 6, a winding wheel 7, a bamboo chip 8 and a wire sensor, The front baffle 2 is installed on the two legs 1, and the back baffle 3 is installed on the other two legs 1. The front baffle 2 is provided with a first bamboo detection through hole, and the back baffle 3 is provided with a second bamboo detection hole. The sheet detection through hole, the bamboo sheet 8 passes through the first bamboo sheet detection through hole and the second bamboo sheet detection through hole, a detection lever 5 is provided between the front baffle 2 and the rear baffle 3, and the bracket ear 4 is installed on the front baffle. On the board 2, one end of the detection lever 5 is rotationally connected with the bracket ear 4, and the other end of the detection lever 5 is equipped with a winding wheel 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com