A liquid crystal screen alignment offset defect detection method

A technology of alignment offset and defect detection, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems that affect the detection efficiency, cannot obtain clear images of two objects at the same time, increase the complexity of the process, and achieve low cost, The Effect of Fast LCD Screen Alignment Offset Detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

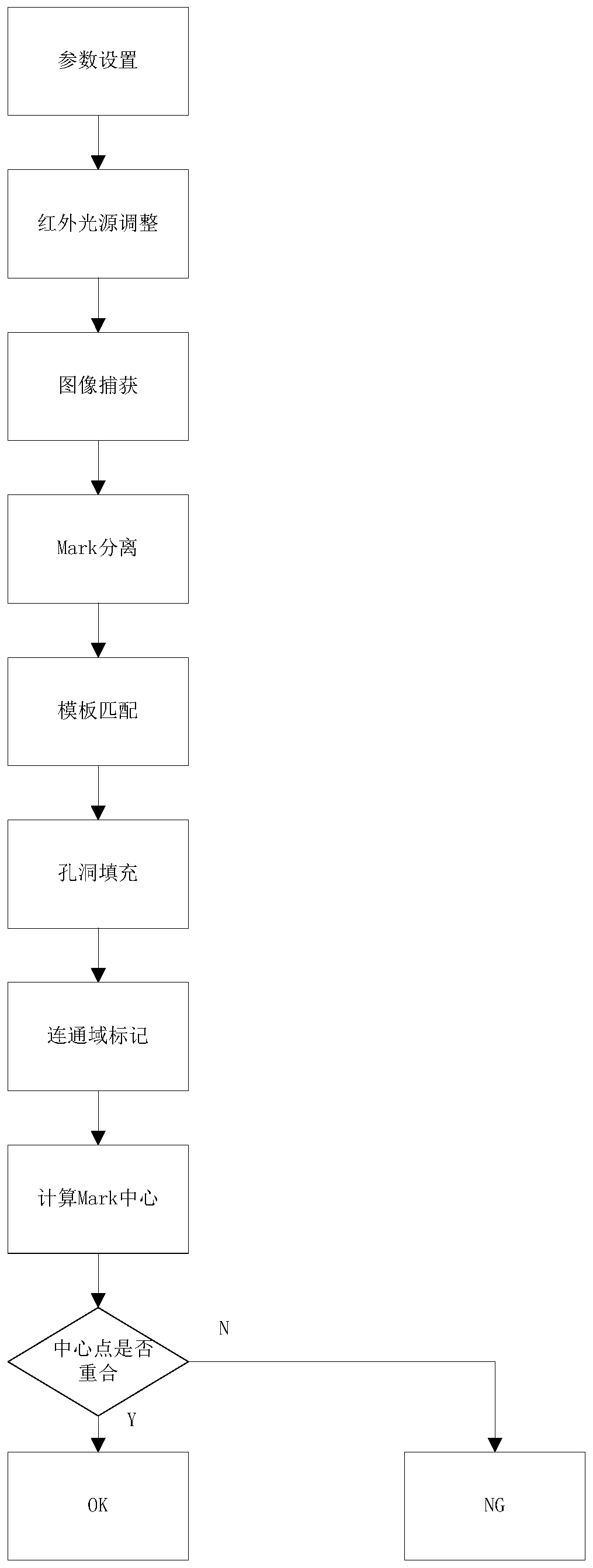

[0021] Example: see figure 1 , a liquid crystal screen alignment defect detection method, the components of the liquid crystal screen to be tested include polarizers, glass, ITO electrodes, PI, and liquid crystals, and the method steps are as follows:

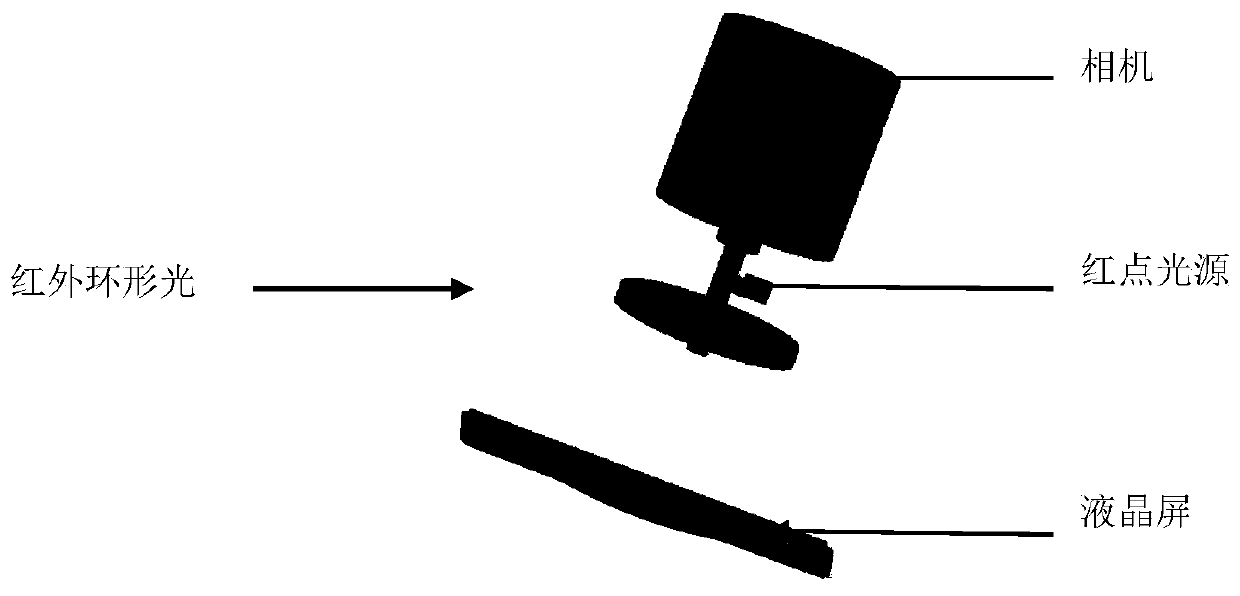

[0022] (1) The model of each part of the optical system is selected, and the optical system includes a camera, a lens, a point light source and an infrared light source;

[0023] Choose a camera with a wide spectral response area, which can perform the best effective response at 380NM to 1100NM; choose a coaxial telecentric lens as the best lens, with low distortion rate, strong magnification selectivity and high resolution

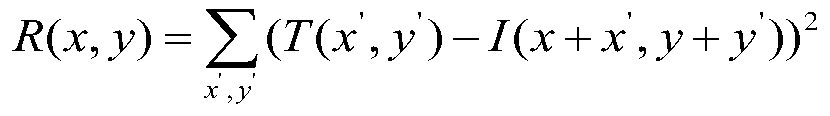

[0024] (2) Refer to figure 2 Install cameras, lenses, coaxial red light and ring-shaped infrared light sources, and LCD screens to be tested, test the imaging effects of different bands of infrared light sources and illumination heights, and determine the optimal band and installation height of the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com