Method for improving shearing width precision of strip steel

A strip steel, high-precision technology, applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

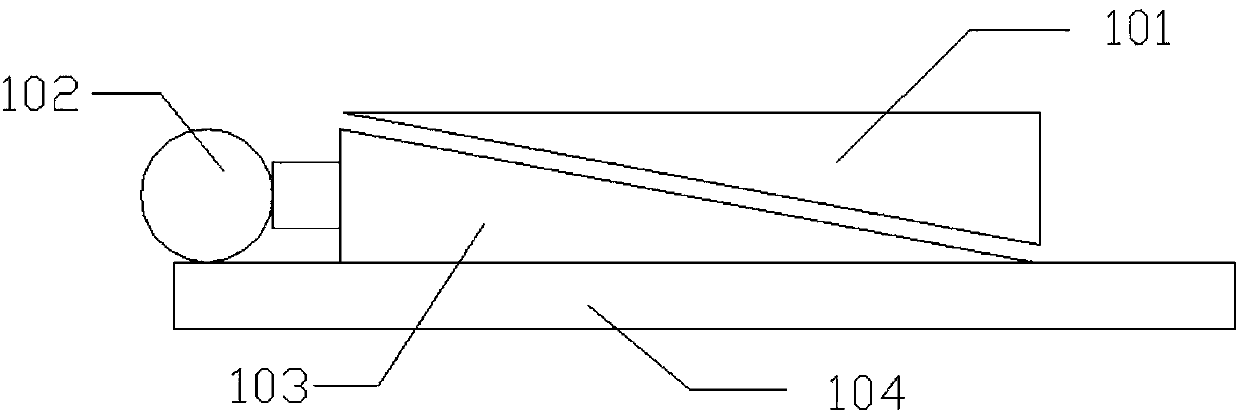

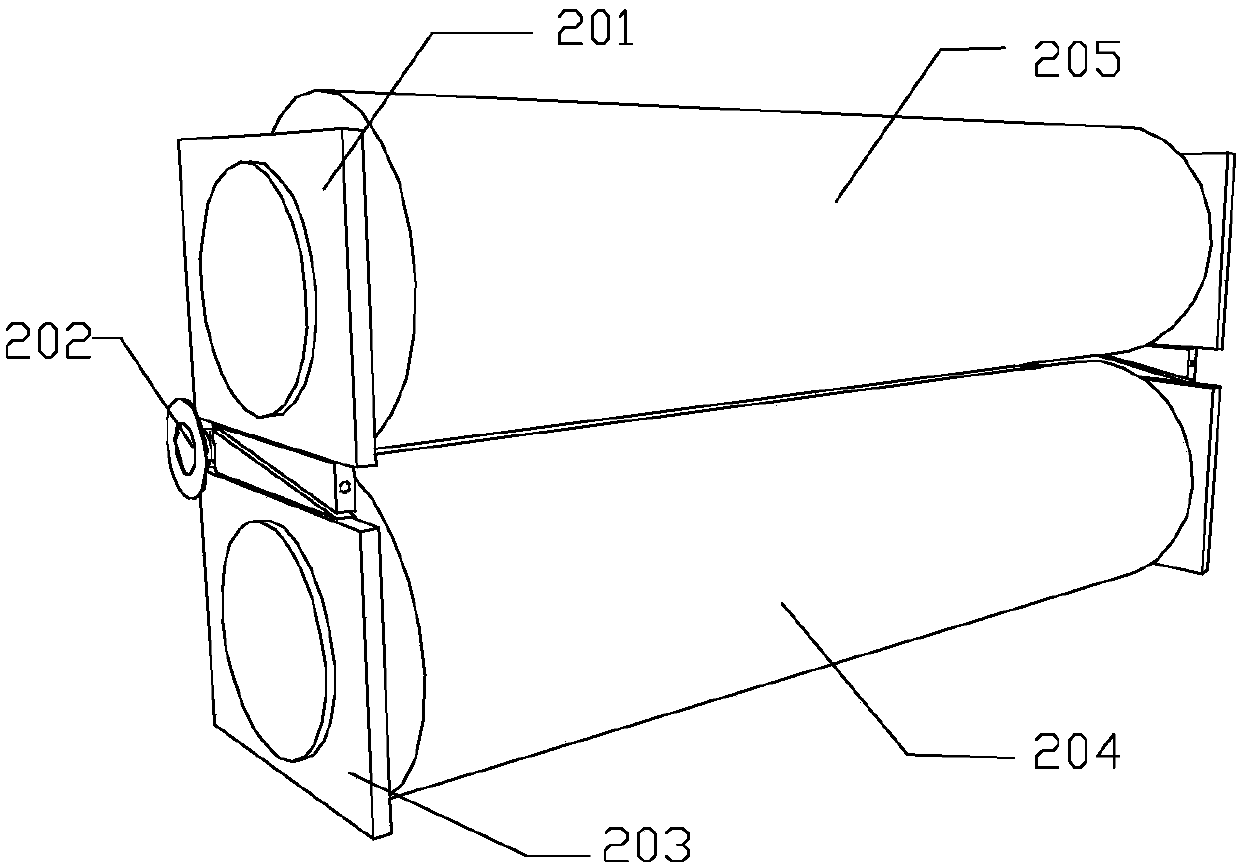

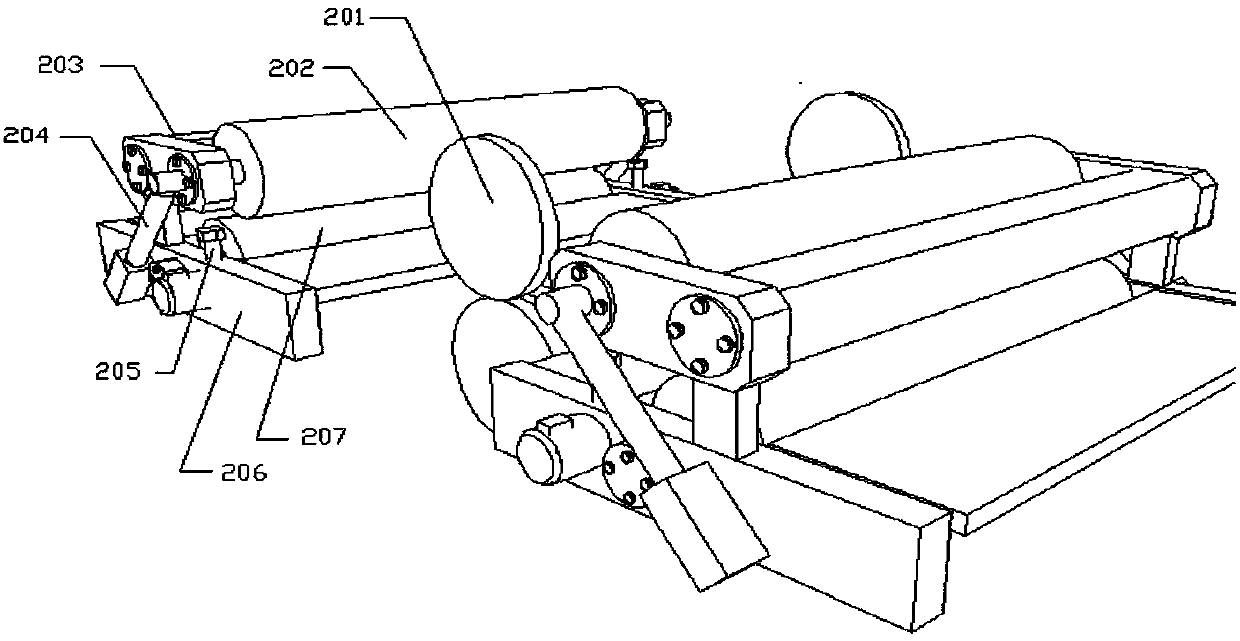

[0047] like figure 1 , 2 Shown, control method of the present invention comprises the following steps:

[0048] A set of roll gap adjustment devices are respectively placed on both sides of the main pinch roll of the production line, through the (102) roll gap adjustment screw, the linkage control (103) roll gap lower slope control device drives the (101) upper slope control device , wherein (104) is a frame integrated with the main pinch roller. (202) roll gap control disc drives (102) roll gap adjustment screw linkage control (103) roll gap lower slope control device drives (204) main pinch roller lower roll, (101) upper slope and (201) roller machine The frame is connected to drive (205) the upper roll of the main pinch roller. Because the two-side roll gap is adjusted through the (102) roll-gap adjustment screw linkage, so as to reduce the error during the adjustment of the two-side roll gap, improve the roll gap control accuracy, and ensure the tension when the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com