Hydrostatic pressure test system and test method for realizing hydrostatic pressure of steel pipe

A hydrostatic test and hydrostatic pressure technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, and measuring devices. Sealing requirements and other issues, to achieve the effect of large promotion value, ensure accuracy, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

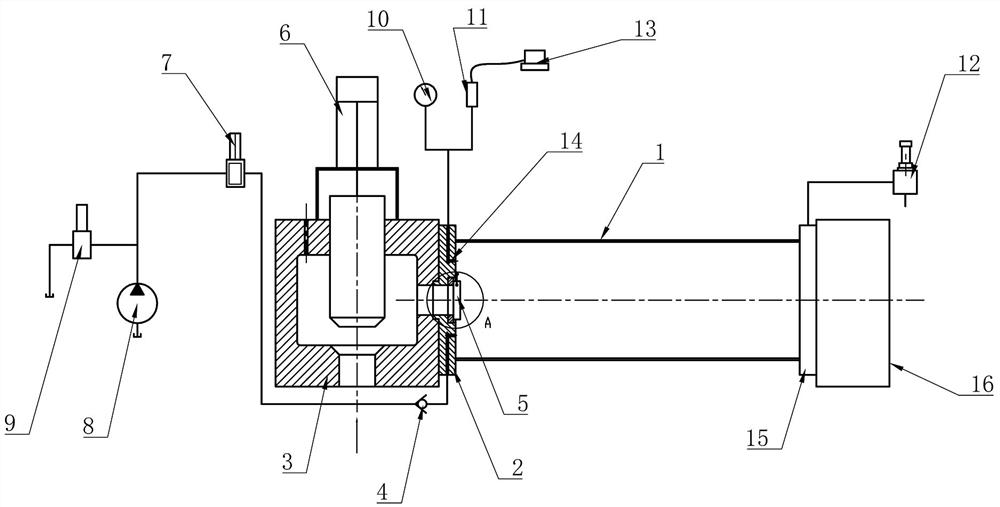

[0037] Such as Figure 1-7 Among them, a hydrostatic test system and test method for a steel pipe to realize hydrostatic pressure, including a first head 2 and a second head 15 installed at both ends of a steel pipe 1, and one side of the first head 2 is provided with a pressure maintaining device 5. A pressure measuring point 14 is provided on the first head 2, and a second pipeline 202 is also provided on the first head 2;

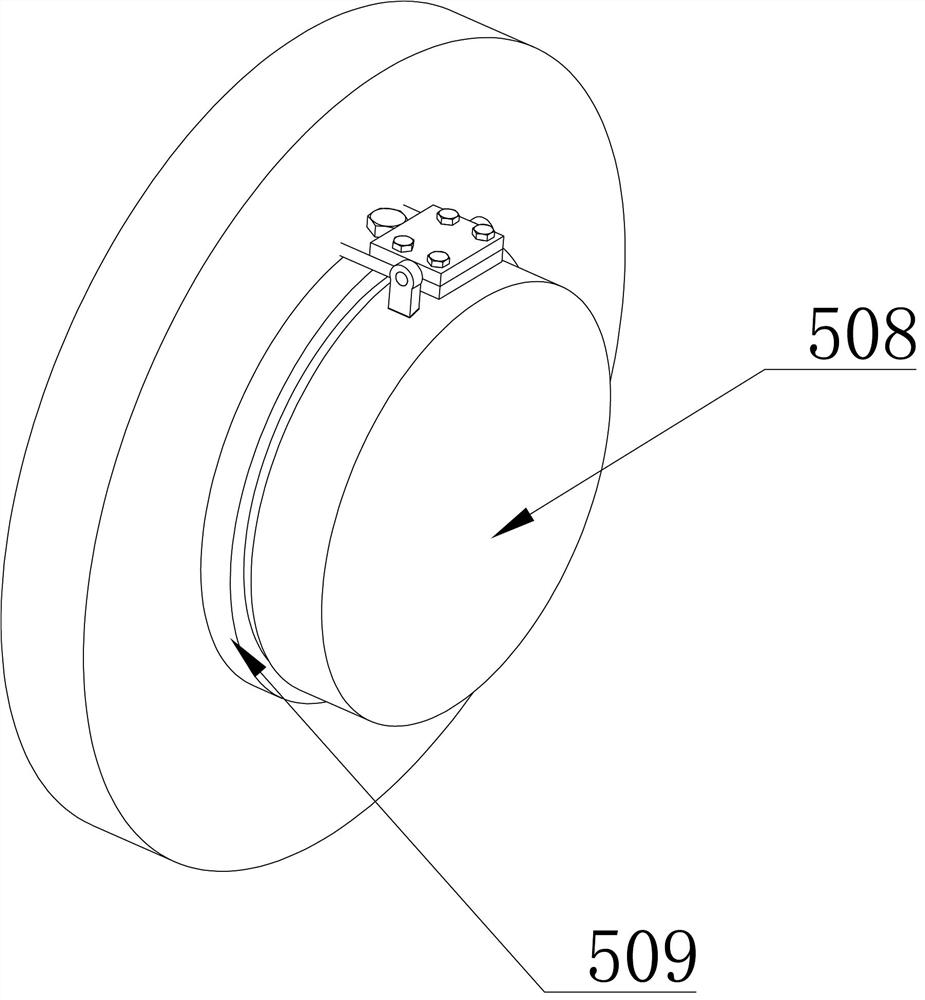

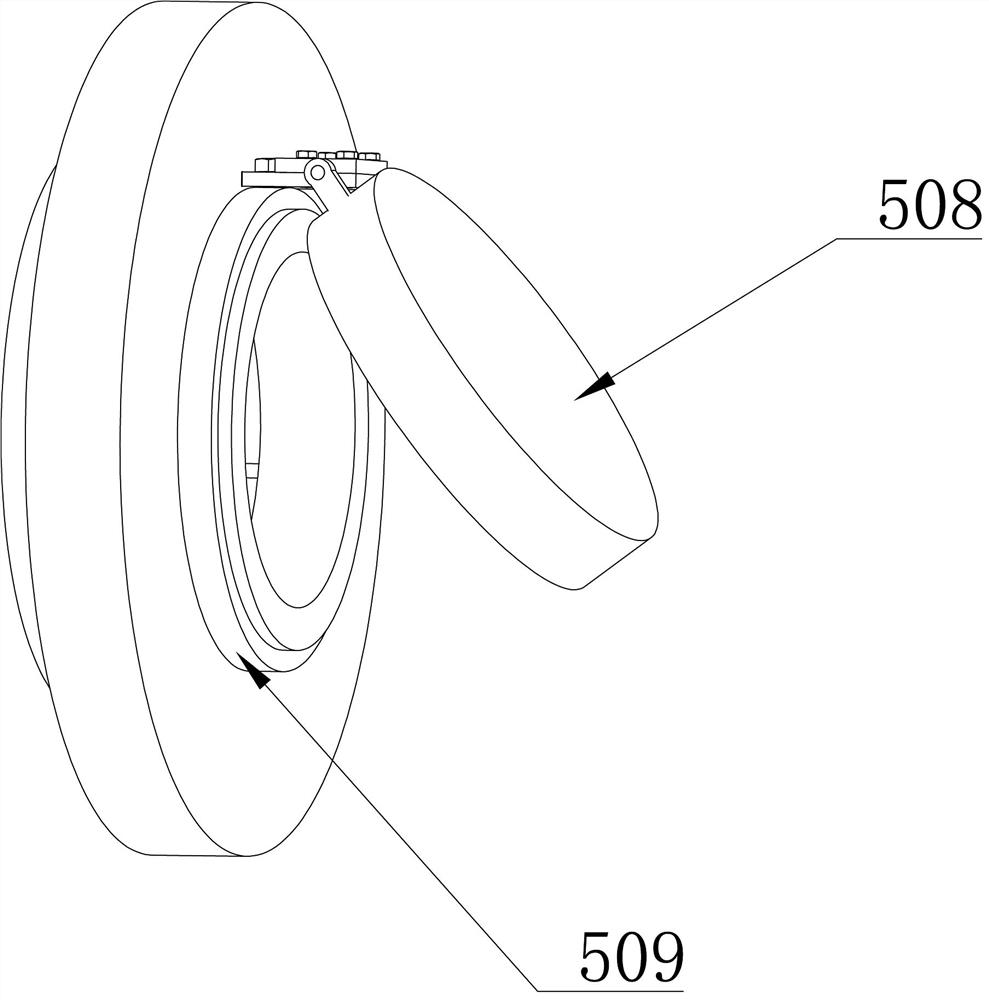

[0038]Drive the low-pressure water to fill the steel pipe 1, and the pressure-holding device 5 is automatically opened. After flushing the steel pipe 1, the pressure-holding device 5 is automatically closed under the action of gravity. seal. With this structure, during the water filling process of the steel pipe, the valve is automatically opened, and after the water filling in the pipe is completed, the valve is closed under the action of gravity, and the valve is pressed tightly by high-pressure water during the pressurization process to realize seali...

Embodiment 2

[0049] Further illustrate in conjunction with embodiment 1, as Figure 1~7 As shown, the method is: S1. Install the pressure maintaining device 5 on the first head 2, transport the steel pipe 1 between the first head 2 and the second head 15 with a rail trolley, and use the clamping device 16 Hold the steel pipe 1 and connect it to the test system in sequence. Lift the hydraulic cylinder 6 so that the sealing spool 601 is pulled out from the low-pressure water inlet 301, and the channel of the low-pressure water inlet 301 is opened. Use a low-pressure water supply device to inject water into the cylinder body 3 through the low-pressure water inlet 301, and the water in the cylinder body 3 fills the steel pipe 1 through the water injection port 302. The momentum of the water flow in the cylinder body 3 automatically opens the valve plate 508. After the water injection in the steel pipe 1 is completed, the valve plate 508 of the pressure maintaining device 5 is automatically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com