Make-up method for color masters in production of PVC (polyvinyl chloride) tubes and device

A technology of PVC pipe and color masterbatch, which is applied in the field of PVC pipe production equipment, can solve problems such as difficulty in handling, and achieve the effects of avoiding pollution, increasing mixing uniformity, and increasing the discharge of air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

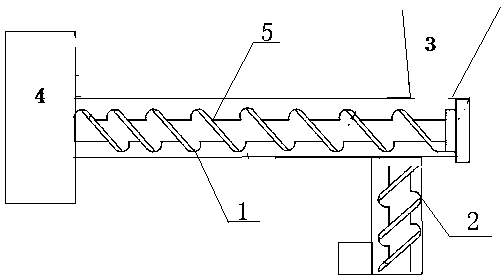

[0016] Embodiment 1: as figure 1 As shown, the dosing device of the color masterbatch in the production of PVC pipes includes a feeding screw conveyor, and the two ends of the feeding screw conveyor 1 are respectively a feed hopper 3 and an extrusion head 4. The improvement of this device lies in the color masterbatch In the mixing stage, a color masterbatch screw conveyor 2 is additionally connected to the barrel of the feeding screw conveyor 1, and the color masterbatch screw conveyor 2 will be used to squeeze the color masterbatch into the feeding screw conveyor and prepare The material of PVC pipe is mixed. In order to make the mixing more uniform, the color master screw conveyor 2 is connected to the feeding section of the feeding screw conveyor 1; at the same time, the feeding control device is connected to the color master screw conveyor 2 to realize the masterbatch The perfect match of material and color masterbatch. At the same time, when making the thread of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com