Follow-up external rearview mirror for vehicle

A technology for exterior rearview mirrors and rearview mirrors, which is applied in the field of automobile rearview mirrors, and can solve problems such as affecting the driver's distance judgment, small curvature radius, and ineffective reduction of blind spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

[0031] An embodiment of the present invention provides a follow-up exterior rearview mirror for a vehicle.

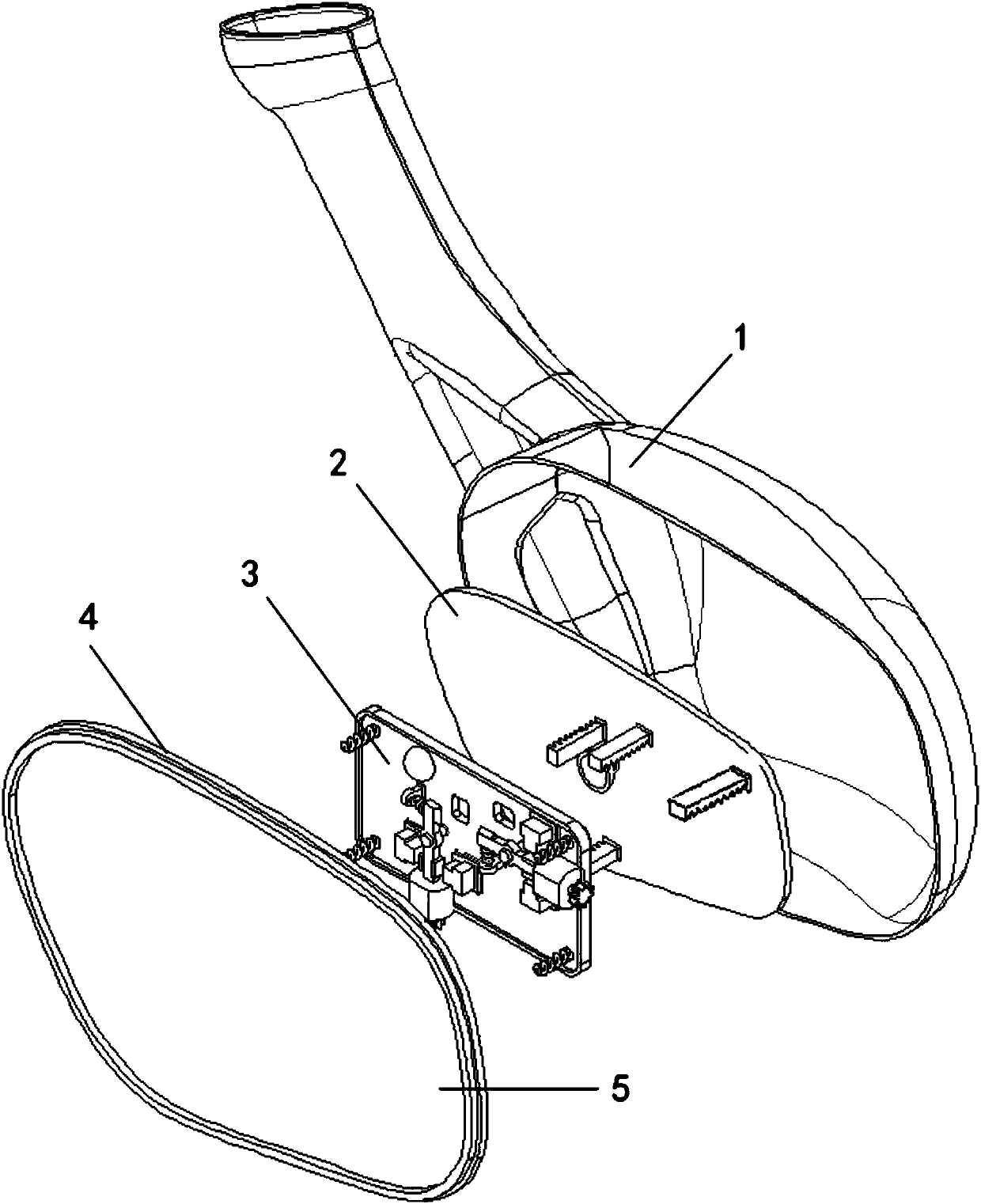

[0032] Such as figure 1 As shown, the follow-up exterior rearview mirror includes an exterior rearview mirror housing 1 , a rearview mirror frame 2 , a motor seat 3 , a lens seat 4 and a lens 5 . The outer rearview mirror housing 1 is rigidly connected with the rearview mirror frame 2; the outer rearview mirror frame 2 is connected with the motor seat 3; the motor seat 3 is connected with the lens seat 4;

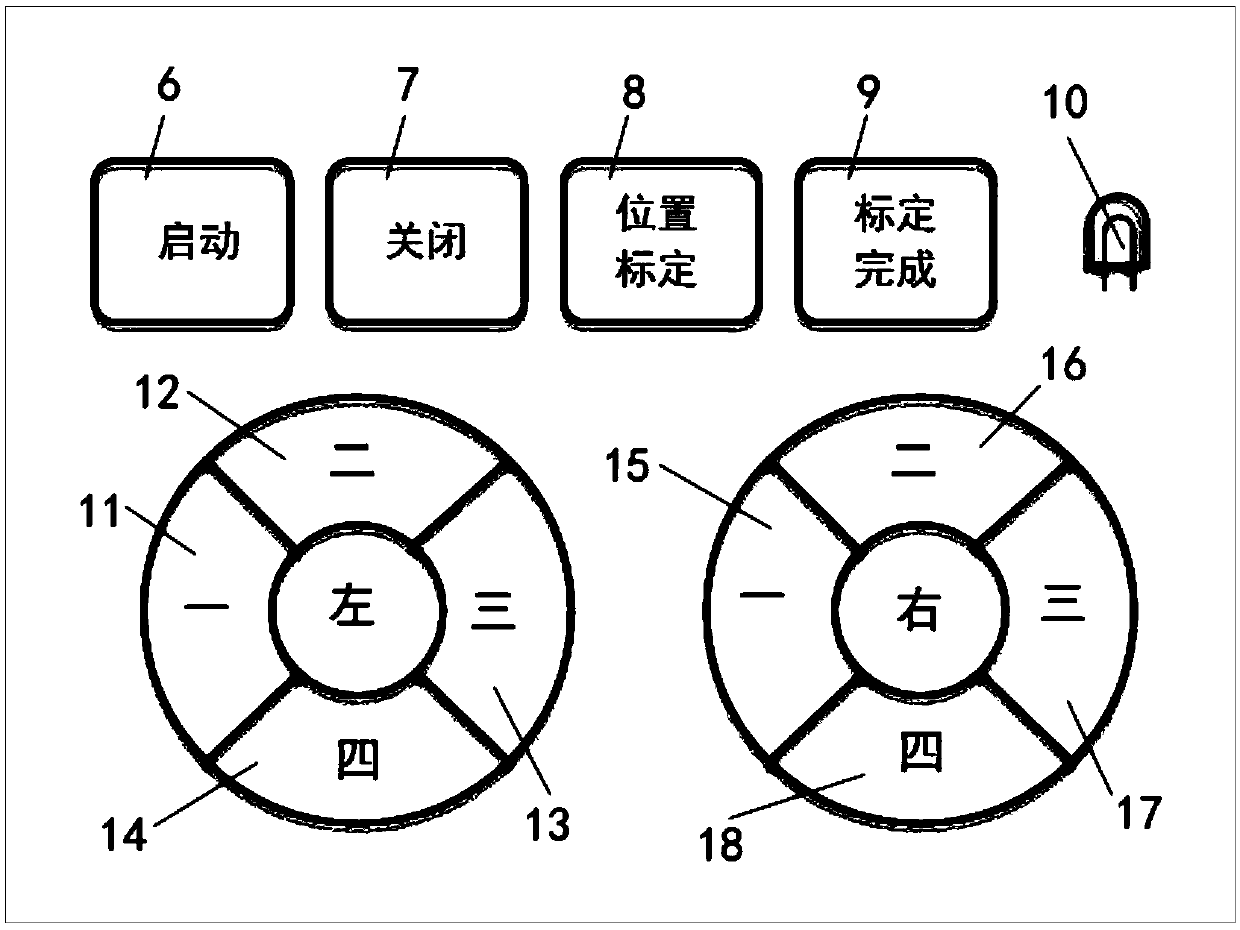

[0033] Such as figure 2As shown, the control panel includes four buttons, two groups of function keys and a status indicator. The start button 6 is used to start or restart the follow-up exterior rearview mirror system. The off button 7 turns off the follow-up exterior rearview mirror system. Position calibration key 8 is used for positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com