Practical cloth winding device for rapid winding of textile fabric

A textile fabric, fast technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of reducing corporate profits, consuming manpower and time, and affecting the rolling process, so as to improve work efficiency and reduce Manual operation, the effect of improving the work efficiency of cloth rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

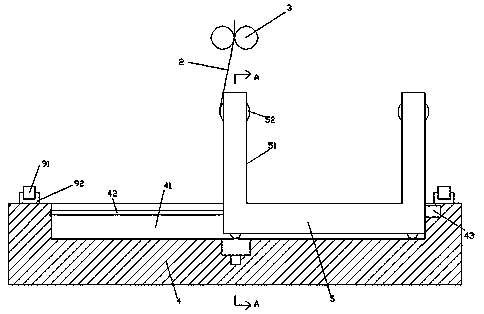

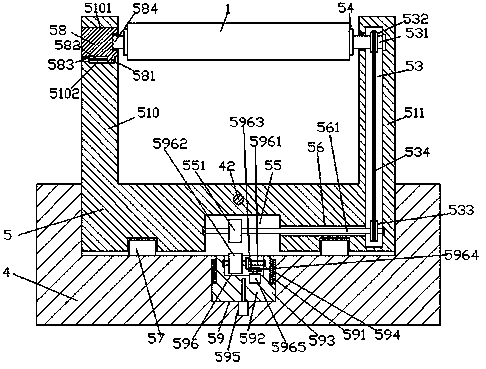

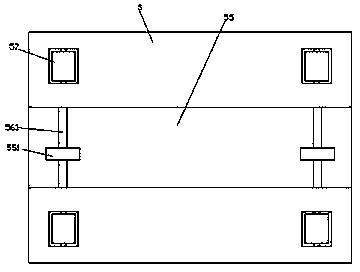

[0025] Such as Figure 1-Figure 6 As shown, a practical cloth rolling device for fast winding of textile cloth according to the present invention includes a machine base 4 and a guide roller 3 arranged above the top of the machine base 4 and opposite to the left and right. There is a first guide chute 41, which slides and fits to connect the sliding bottom bracket 5 in the first guide chute 41, and the middle position of the inner bottom wall of the first guide chute 41 is provided with a lifting chute 59, and the lifting chute 59 The inner walls of the front and rear sides of the groove 59 are symmetrically provided with a second guide chute 591, and the lift chute 59 is provided with a lift slider 592, and the front and rear sides of the bottom of the lift slide 592 are respectively provided with a first guide groove extending into the front and rear sides. The first guide slider 593 in the second guide chute 591, the middle position of the bottom end surface of the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com