External inserting type funnel

A technology of funnel and funnel tube, which is applied in the field of household dumping, and can solve problems such as difficult flow of large granular objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

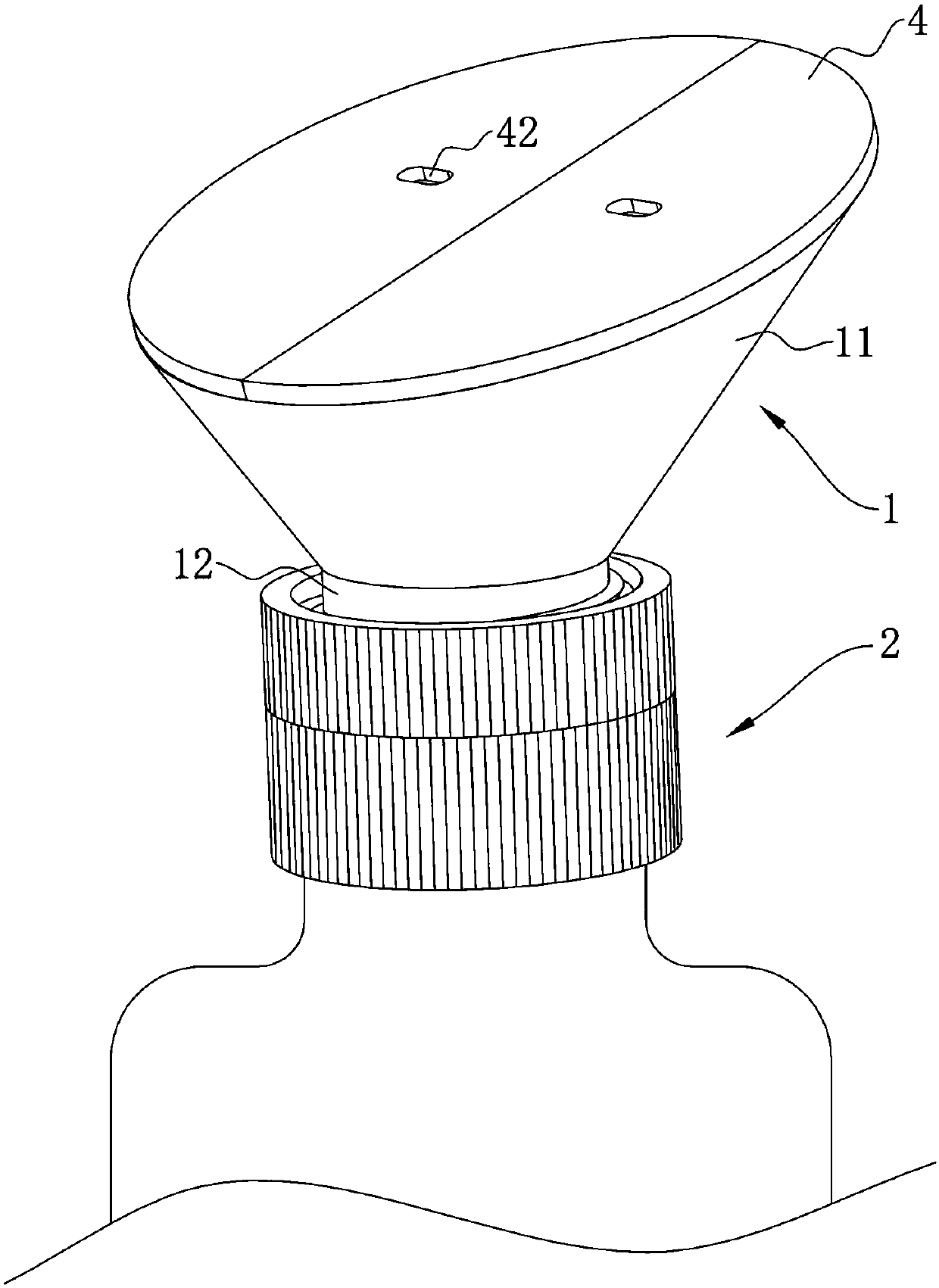

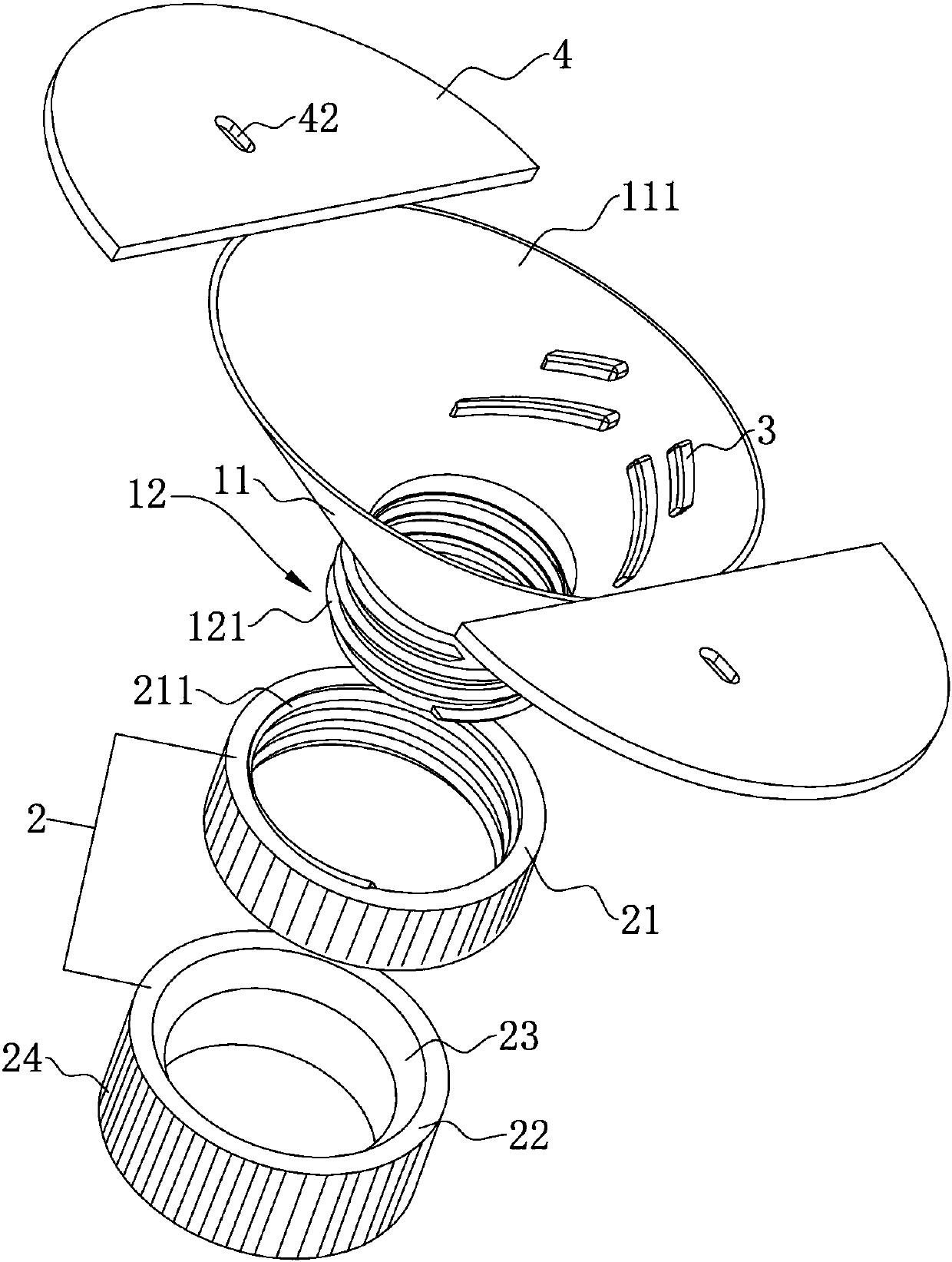

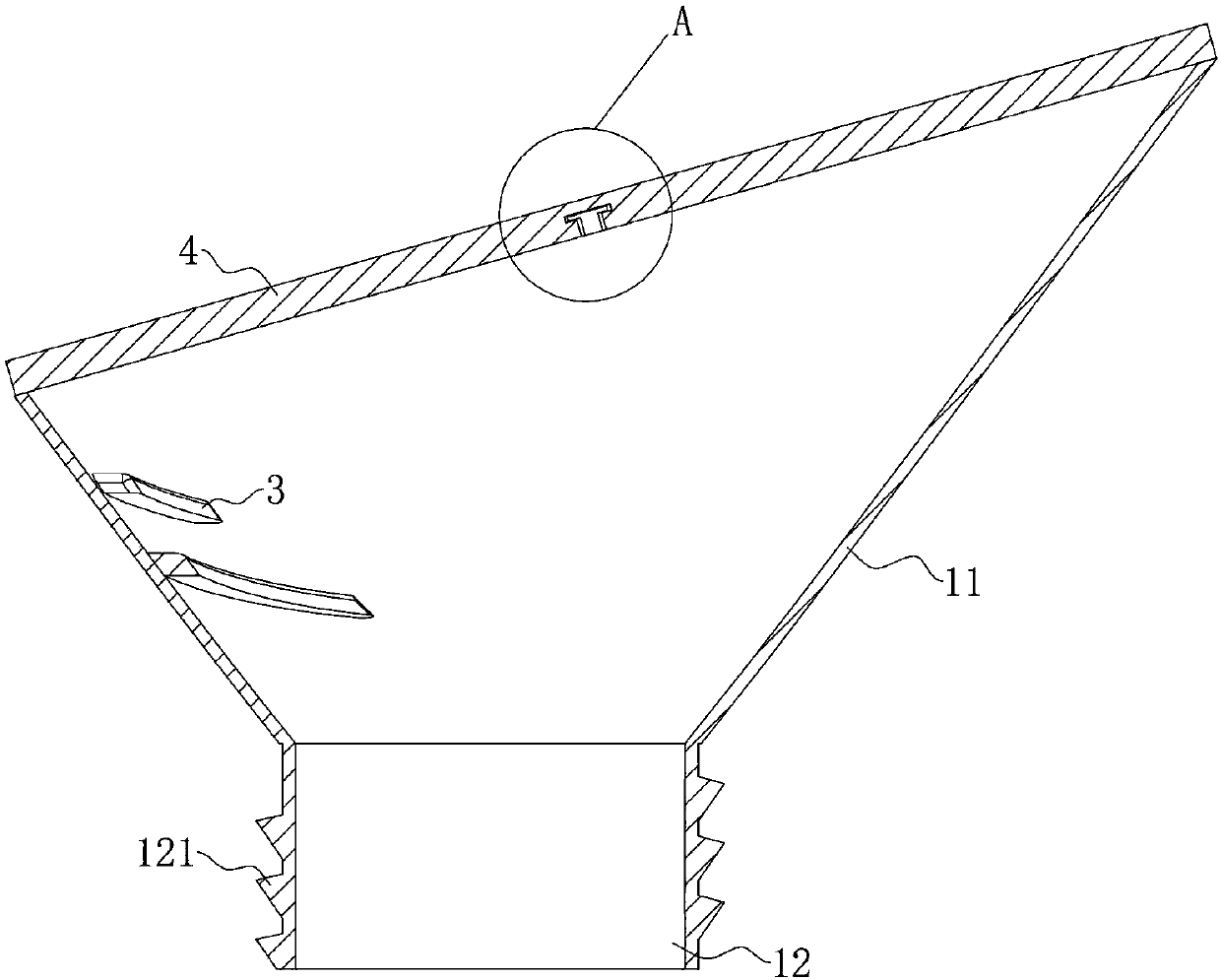

[0032] Such as figure 1 with figure 2 As shown, the present invention provides an externally inserted funnel, which includes a funnel body 1 and a funnel connector 2 installed on the funnel body 1 . The funnel body 1 includes a funnel tube 11 and a funnel tube 12 integrally formed at the bottom of the funnel tube 11. The upper port of the funnel tube 11 forms a feed inlet 111 along an inclined surface. The funnel tube 12 is cylindrical, and the length of the funnel tube 12 is less than The length of the funnel barrel 11, the funnel connector 2 is fitted on the funnel tube 12, and the end of the funnel connector 2 away from the funnel tube 11 is fitted on the container mouth, and the funnel body 1 is fixed by the external plug-in installation of the funnel connector 2 On the mouth of the container, the space for the flow of poured objects in the funnel tube 12 is increased to facilitate the flow of large particle objects from the funnel body 1 into the container. In order to...

Embodiment 2

[0039] Such as Figure 5 As shown, the difference from Embodiment 1 is that the upper connector 21 and the lower connector 22 are cylindrical, and the inner diameter of the upper connector 21 is smaller than the inner diameter of the lower connector 22, and the upper connector 21 and the lower connector 22 The connection of the funnel body 1 forms a boss shape in the funnel connector 2, and the funnel body 1 and the container are installed in the upper connector 21 and the lower connector 22 respectively, so that the funnel body 1 can be installed outside the funnel pipe 12 with a diameter larger than that of the funnel. diameter container.

Embodiment 3

[0041] Such as Image 6 As shown, the difference from Embodiment 1 is that the upper connector 21 and the lower connector 22 are cylindrical, and the inner diameter of the upper connector 21 is greater than the inner diameter of the lower connector 22, and the upper connector 21 and the lower connector 22 The connection of the funnel body 1 forms a boss shape in the funnel connector 2. By fitting the funnel body 1 and the container in the upper connector 21 and the lower connector 22 respectively, it is convenient to install the funnel body 1 where the caliber is smaller than the inner diameter of the funnel tube 12. container.

[0042] In the externally inserted funnel of the present invention, the funnel tube is designed to be cylindrical, and the corresponding funnel connectors are installed in conjunction with it, and different funnel connectors are installed on the corresponding container mouths in an externally inserted manner to increase the amount of pouring in the fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com