Composite explosion-proof valve, cover plate assembly and battery

A technology of explosion-proof valve and cover plate, which is applied in the direction of secondary battery, battery pack parts, and secondary battery repair/maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

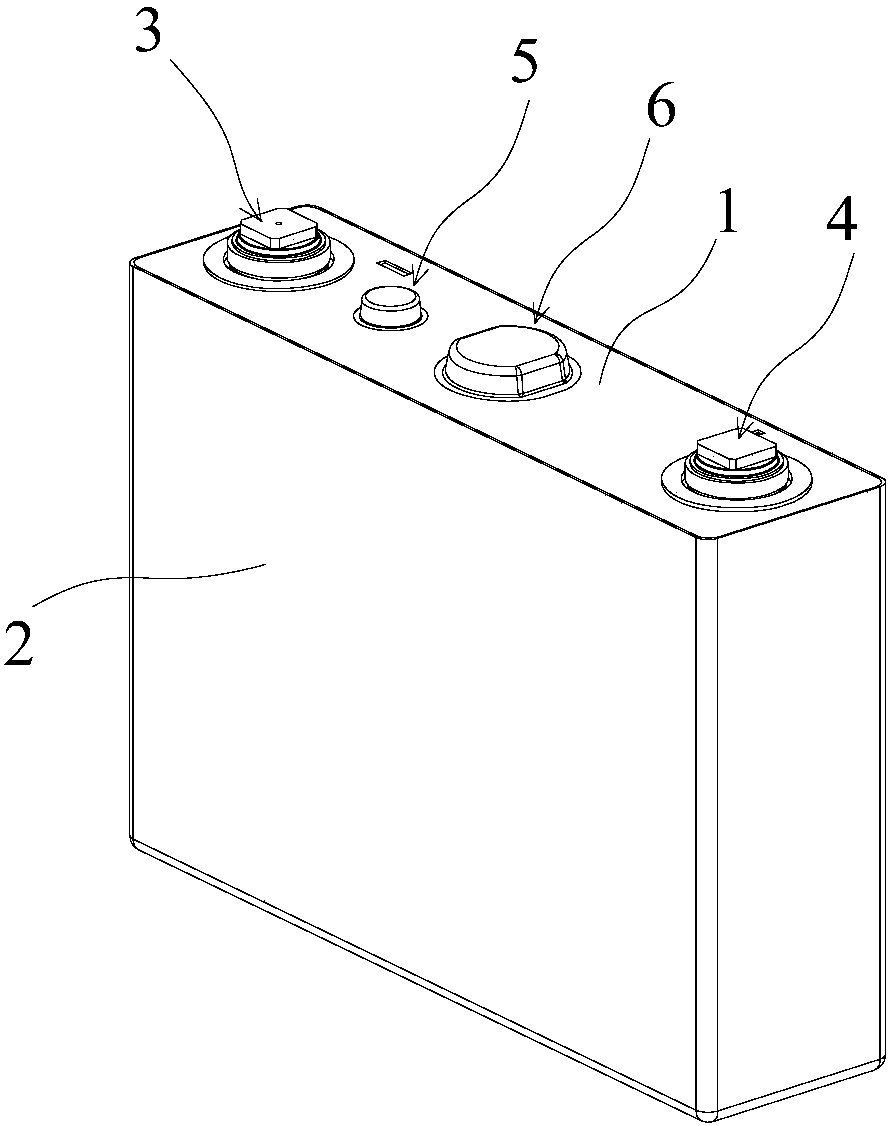

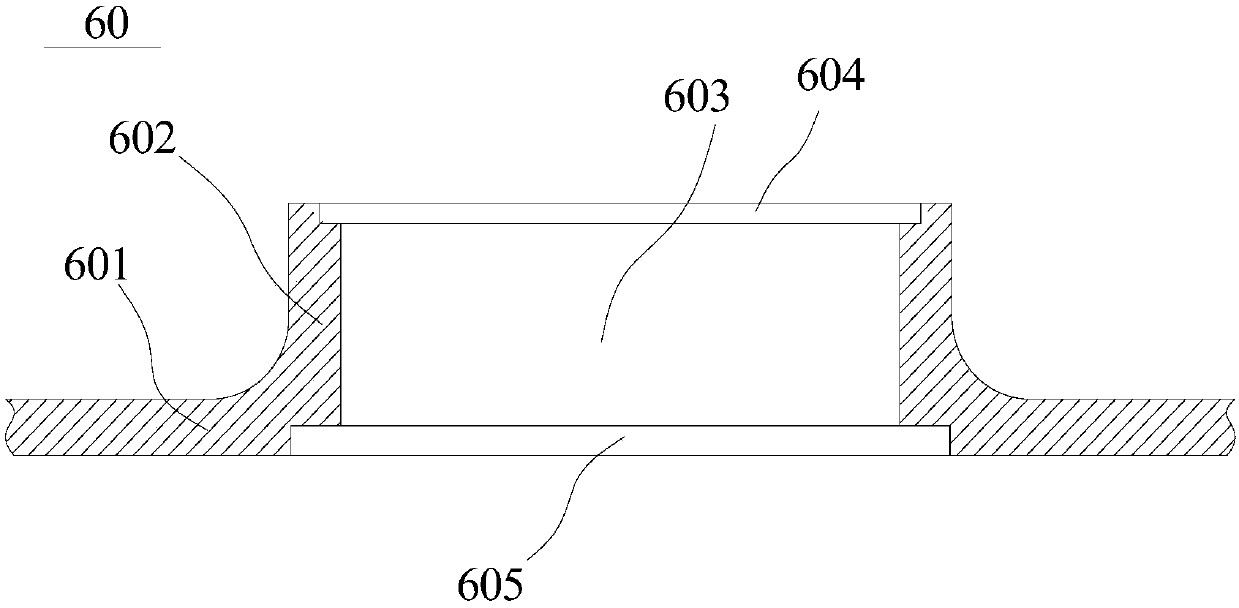

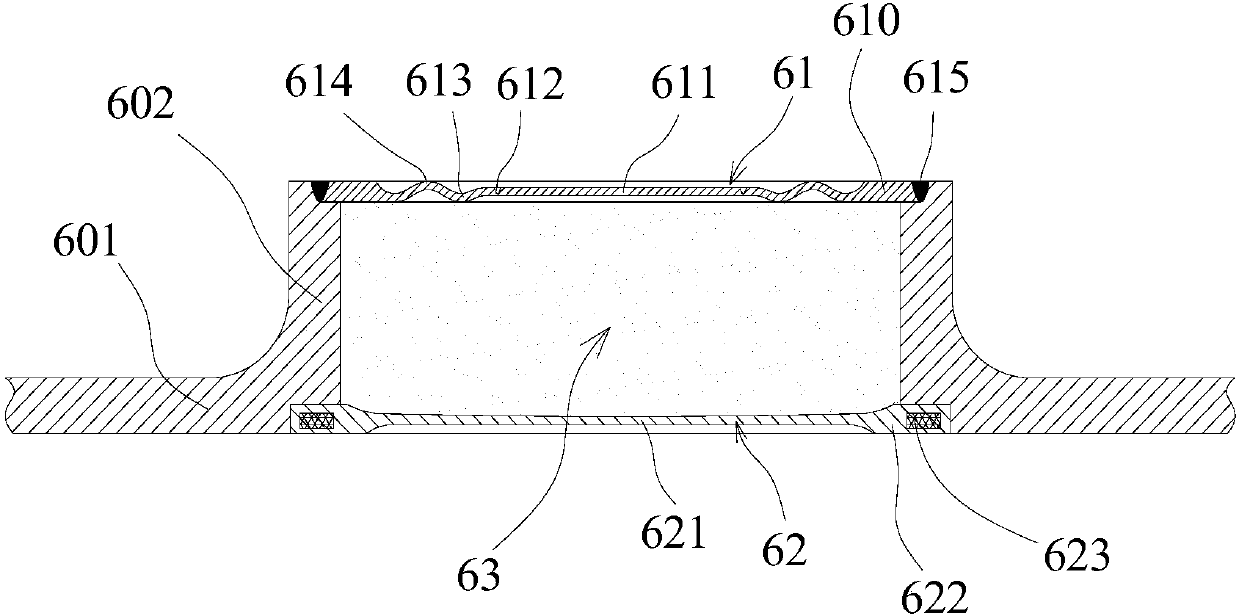

[0050] This example will specifically explain the battery, the cover plate assembly and the composite explosion-proof valve 6 disclosed in the present invention.

[0051] Such as figure 1As shown, this example discloses a battery, the battery includes a case 2, a pole core and a cover plate assembly, the cover plate assembly and the case 2 form a closed space, and the pole core is installed in the closed space. The battery in this example may be a lithium-ion battery, or other types of nickel batteries or lead-acid batteries. The pole core is formed by winding or stacking positive electrode sheets, separators, and negative electrode sheets, which is known to the public. Wherein, the above-mentioned cover plate assembly includes a cover plate body 1 on which a compound explosion-proof valve 6 is installed. Wherein, generally, the first electrode assembly 3 and the second electrode assembly 4 with different polarities are insulated and installed on the cover plate assembly. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com