Multifunctional polytetrafluoroethylene process frame for experiment

A polytetrafluoroethylene, multi-functional technology, applied in the direction of laboratory appliances, test tube holders/clamps, supporting appliances, etc., can solve the problems of damage to organic reagents and process racks, poor corrosion resistance, and mutual collision of organic reagents, etc., to achieve Effective corrosion resistance, improved stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

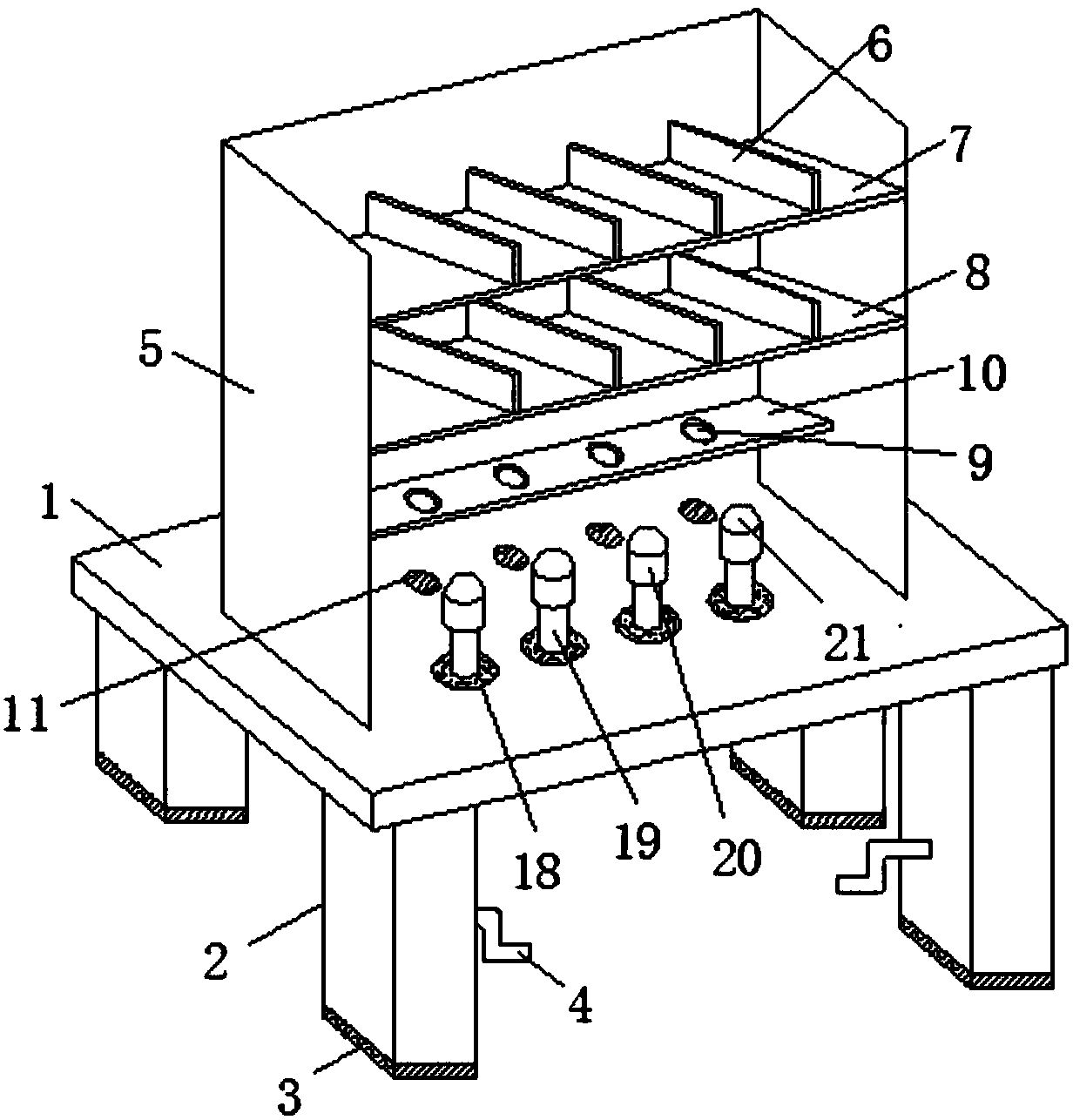

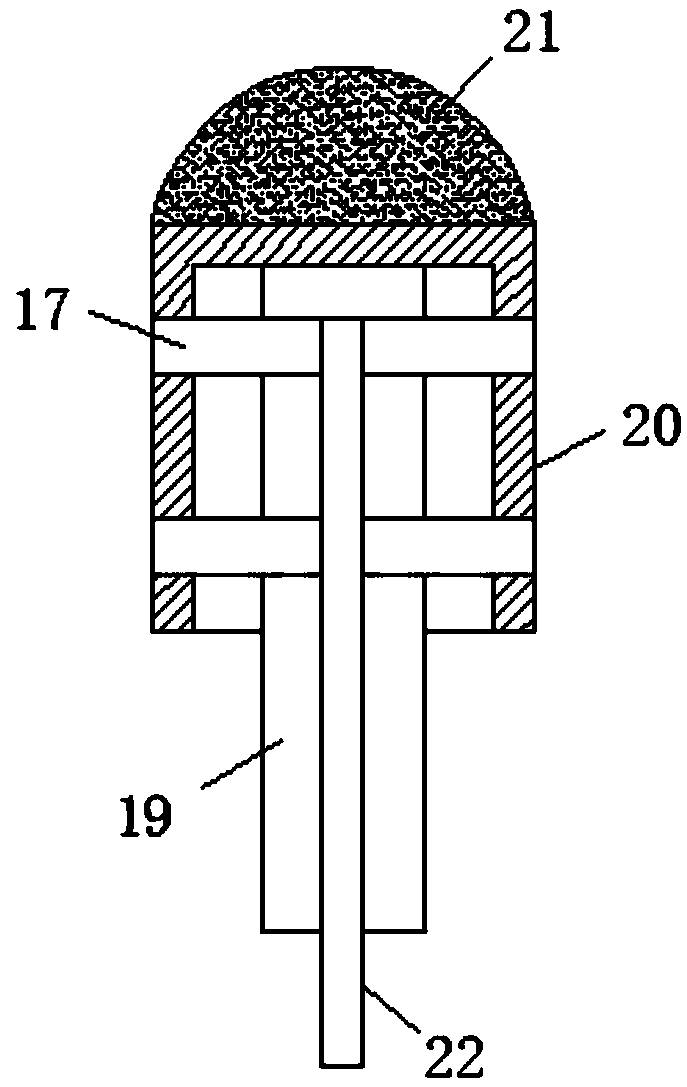

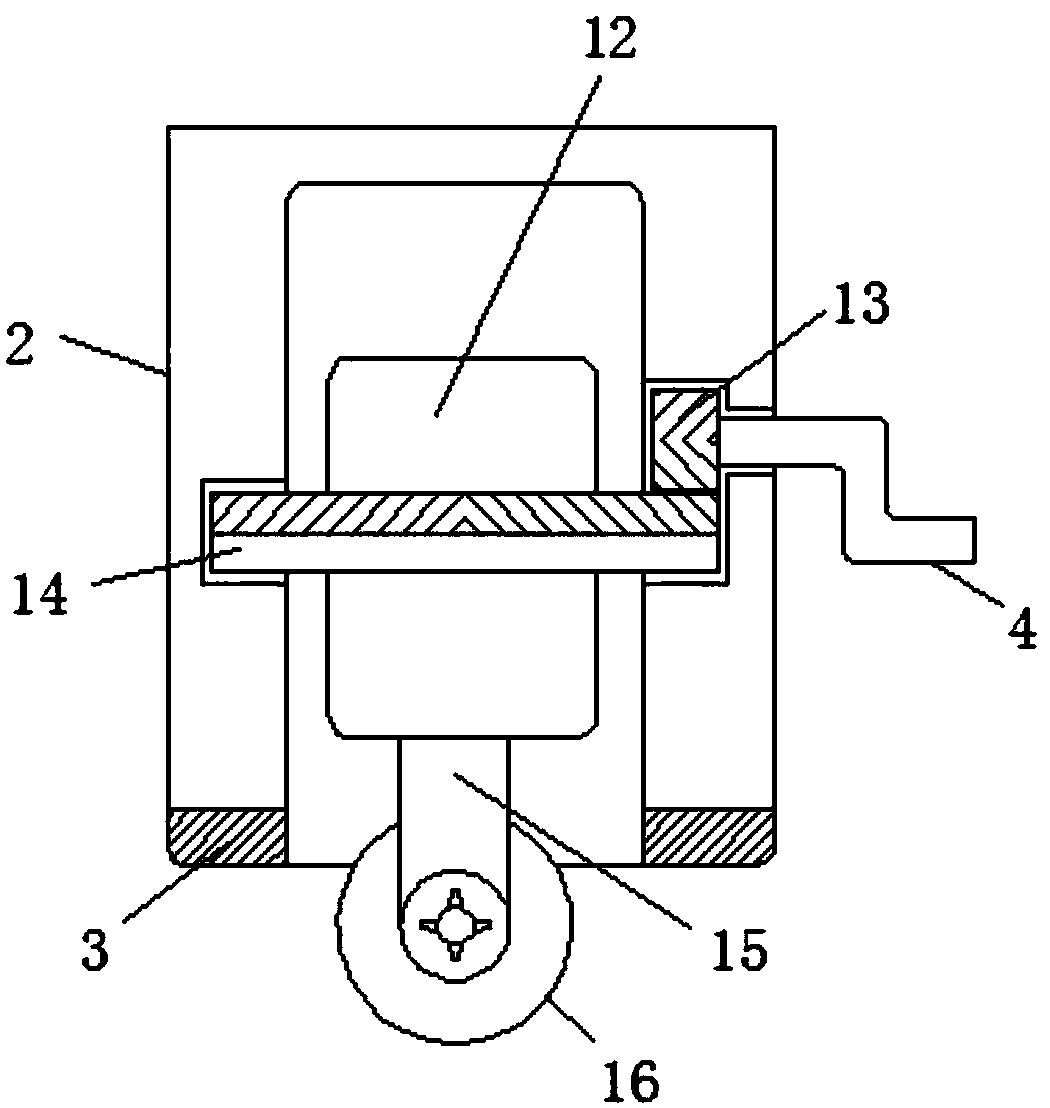

[0019] refer to Figure 1-3 , a multifunctional polytetrafluoroethylene process frame for experimentation, comprising a workbench 1, the upper end of the workbench 1 is provided with a frame body 5, and the inner wall of the frame body 5 is sequentially provided with a first loading plate 7, The second loading board 8 and the third loading board 10, the upper ends of the first loading board 7 and the second loading board 8 are evenly distributed with several spacers 6, and the upper end of the third loading board 10 is penetrated with several spacers. a through hole 9, the upper end of the workbench 1 is provided with a cushion 11 below the through hole 9, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com